Produkt ähnlich wie:

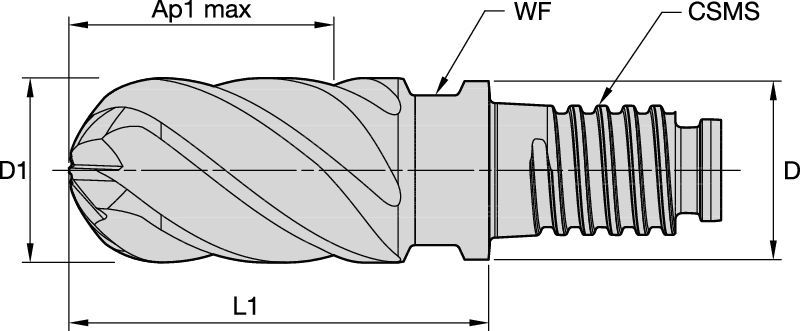

DUO-LOCK™ • HARVI™ III • Ball Nose • 6 Flutes • Inch

HARVI III Ball Nose • UJBV • Unequal Flute Spacing • Eccentric Relief

Material Nummer6072145

ISO Katalog NummerUJBV0500Y6CNANSI Katalog NummerUJBV0500Y6CN

- P Stahl

- M Rostfreier Stahl

- K Gusseisen

- S Hochwarmfeste Legierungen

- H Gehärtete Werkstoffe

Helix Angle: 37°/39°

Umfangfräsen/Schulterfräsen: Kugelkopf / Vollradius

3D-Profilfräsen/Kopierfräsen

Werkzeugabmessungen: Schneidreihen: 6

Corner Style: Ball Nose

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 6072145 |

| ISO Katalog Nummer | UJBV0500Y6CN |

| ANSI Katalog Nummer | UJBV0500Y6CN |

| Sorte | KCSM15 |

| Aufnahmeart Maschinenseite | DUO-LOCK |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 12.2 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | .4803 in |

| [AP1MAX] 1. maximale Schnitttiefe | 19.05 mm |

| [AP1MAX] 1. maximale Schnitttiefe | .75 in |

| [L1] Messlänge | 28.6 mm |

| [L1] Messlänge | 1.126 in |

| [CSMS] Systemgröße – Maschinenseite | DL12 |

| [WF] Flächenbreite | 9.5 mm |

| [WF] Flächenbreite | .374 in |

| [Z] Anzahl der Spannuten | 6 |

| [D1] Effektiver Schneidendurchmesser | 12.7 mm |

| [D1] Effektiver Schneidendurchmesser | .5 in |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Gusseisen

- Hochwarmfeste Legierungen

- Gehärtete Werkstoffe

Uses and application

Helix Angle: 37°/39°

Umfangfräsen/Schulterfräsen: Kugelkopf / Vollradius

3D-Profilfräsen/Kopierfräsen

Werkzeugabmessungen: Schneidreihen: 6

Corner Style: Ball Nose

Grades

KCSM15

Hartmetallschneidstoff mit einer dicken, prozessoptimierten PVD-Beschichtung mit einer höheren Verschleißfestigkeit. Überragender Schutz vor Kolk-, Kerb- und Freiflächenverschleiß bei der Bearbeitung von Stahl und nicht rostendem Stahl. Ausgezeichnete Leistung bei Härten von bis zu 52 HRC.

Features and benefits

- Unequal flute spacing and variable helix configuration minimize chatter and harmonics for smoother machining.

- Center cutting.

- Optimized geometry for titanium machining.

- Single tool for both roughing and finishing, reducing setups.

- Standard items listed. Additional styles and coatings made-to-order.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Toleranz

| Toleranzen für Schaftfräser | |

| D1 | Toleranz e8 |

| 13/32 | -0,00126"/-0,00232" |

| 23/32 | -0,00157"/-0,00287" |

| -0,00197''/-0,00350'' | |

Anwendungsdaten

HARVI III Ball Nose • UJBV • Unequal Flute Spacing • Roughing

| Werkstoffgruppe |  |  | ||||||||||||||||

| Schulterfräsen (A) | kurz | mittel | lang | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||||||

| A | Auskraglänge der | D1 | ||||||||||||||||

| KCSM15 | KCSM15 | KCSM15 | ||||||||||||||||

| Schnittgeschwindigkeit | Schnittgeschwindigkeit | Schnittgeschwindigkeit | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||||

| ap | ae | Min. | Max. | Min. | Max. | Min. | Max. | dec. | .3750 | .5000 | .6250 | .7500 | 1.2500 | |||||

| P | 0 | Ap max | 0.4 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 |

| 1 | Ap max | 0.4 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | |

| 2 | Ap max | 0.4 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | |

| 3 | Ap max | 0.4 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | |

| 4 | Ap max | 0.4 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0017 | .0022 | .0026 | .0029 | .0034 | |

| 5 | Ap max | 0.4 x D | 200 | – | 330 | 170 | – | 280.5 | 160 | – | 264 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | |

| 6 | Ap max | 0.4 x D | 160 | – | 250 | 136 | – | 212.5 | 128 | – | 200 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | |

| M | 1 | Ap max | 0.4 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 |

| 2 | Ap max | 0.4 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | |

| 3 | Ap max | 0.4 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | |

| K | 1 | Ap max | 0.4 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 |

| 2 | Ap max | 0.4 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | |

| 3 | Ap max | 0.4 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | |

| S | 1 | Ap max | 0.4 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 |

| 2 | Ap max | 0.4 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0022 | |

| 3 | Ap max | 0.4 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0022 | |

| 4 | Ap max | 0.4 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0014 | .0018 | .0021 | .0024 | .0030 | |

| H | 1 | Ap max | 0.4 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0017 | .0022 | .0026 | .0029 | .0034 |

| 2 | Ap max | 0.4 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | |

HARVI III Ball Nose • UJBV • Unequal Flute Spacing • Finishing

| Werkstoffgruppe |  |  | ||||||||||||||||

| Schulterfräsen (A) | kurz | mittel | lang | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||||||

| A | Auskraglänge der | D1 | ||||||||||||||||

| KCSM15 | KCSM15 | KCSM15 | ||||||||||||||||

| Schnittgeschwindigkeit | Schnittgeschwindigkeit | Schnittgeschwindigkeit | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||||

| ap | ae | Min. | Max. | Min. | Max. | Min. | Max. | dec. | .3750 | .5000 | .6250 | .7500 | 1.2500 | |||||

| P | 0 | Ap max | 0.06 x D | 940 | – | 1250 | 846 | – | 1125 | 846 | – | 1125 | IPT | .0028 | .0035 | .0040 | .0045 | .0050 |

| 1 | Ap max | 0.06 x D | 940 | – | 1250 | 846 | – | 1125 | 846 | – | 1125 | IPT | .0028 | .0035 | .0040 | .0045 | .0050 | |

| 2 | Ap max | 0.06 x D | 870 | – | 1180 | 783 | – | 1062 | 783 | – | 1062 | IPT | .0028 | .0035 | .0040 | .0045 | .0050 | |

| 3 | Ap max | 0.06 x D | 750 | – | 1000 | 675 | – | 900 | 675 | – | 900 | IPT | .0023 | .0029 | .0035 | .0039 | .0049 | |

| 4 | Ap max | 0.06 x D | 560 | – | 940 | 504 | – | 846 | 504 | – | 846 | IPT | .0021 | .0026 | .0031 | .0034 | .0041 | |

| 5 | Ap max | 0.06 x D | 370 | – | 620 | 314.5 | – | 527 | 296 | – | 496 | IPT | .0019 | .0024 | .0028 | .0031 | .0040 | |

| 6 | Ap max | 0.06 x D | 310 | – | 470 | 263.5 | – | 399.5 | 248 | – | 376 | IPT | .0016 | .0020 | .0023 | .0025 | .0029 | |

| M | 1 | Ap max | 0.06 x D | 560 | – | 720 | 448 | – | 576 | 392 | – | 504 | IPT | .0023 | .0029 | .0035 | .0039 | .0049 |

| 2 | Ap max | 0.06 x D | 370 | – | 500 | 296 | – | 400 | 259 | – | 350 | IPT | .0019 | .0024 | .0028 | .0031 | .0040 | |

| 3 | Ap max | 0.06 x D | 370 | – | 440 | 296 | – | 352 | 259 | – | 308 | IPT | .0016 | .0020 | .0023 | .0025 | .0029 | |

| K | 1 | Ap max | 0.06 x D | 750 | – | 940 | 675 | – | 846 | 675 | – | 846 | IPT | .0028 | .0035 | .0040 | .0045 | .0050 |

| 2 | Ap max | 0.06 x D | 690 | – | 870 | 621 | – | 783 | 621 | – | 783 | IPT | .0023 | .0029 | .0035 | .0039 | .0049 | |

| 3 | Ap max | 0.06 x D | 690 | – | 810 | 621 | – | 729 | 621 | – | 729 | IPT | .0019 | .0024 | .0028 | .0031 | .0040 | |

| S | 1 | Ap max | 0.06 x D | 310 | – | 560 | 248 | – | 448 | 186 | – | 336 | IPT | .0023 | .0029 | .0035 | .0039 | .0049 |

| 2 | Ap max | 0.06 x D | 160 | – | 250 | 128 | – | 200 | 96 | – | 150 | IPT | .0012 | .0016 | .0019 | .0021 | .0027 | |

| 3 | Ap max | 0.06 x D | 160 | – | 250 | 128 | – | 200 | 96 | – | 150 | IPT | .0012 | .0016 | .0019 | .0021 | .0027 | |

| 4 | Ap max | 0.06 x D | 310 | – | 370 | 248 | – | 296 | 186 | – | 222 | IPT | .0017 | .0022 | .0026 | .0029 | .0036 | |

| H | 1 | Ap max | 0.06 x D | 500 | – | 870 | 400 | – | 696 | 300 | – | 522 | IPT | .0021 | .0026 | .0031 | .0034 | .0041 |

| 2 | Ap max | 0.06 x D | 440 | – | 750 | 352 | – | 600 | 264 | – | 450 | IPT | .0016 | .0020 | .0023 | .0025 | .0029 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use