Product Similar To:

DUO-LOCK™ • HARVI™ I TE • Chamfered • 4 Flutes • Inch

HARVI™ I TE Four Flute Modular End Mill for Roughing and Finishing Covering the Broadest Range of Applications and Materials

Material Number7136467

ISO Catalog IDH1TE4CH1250R188DLANSI Catalog IDH1TE4CH1250R188DL

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Corner Style: Corner Chamfer

Helical Milling

Ramping: 3°

Side Milling/Shoulder Milling: Square End

Pocketing

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

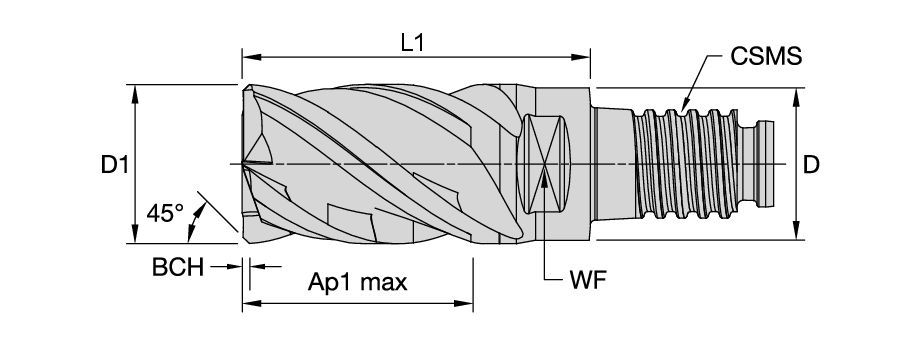

| Material Number | 7136467 |

| ISO Catalog ID | H1TE4CH1250R188DL |

| ANSI Catalog ID | H1TE4CH1250R188DL |

| Grade | KCPM15 |

| Adapter Style Machine Side | DUO-LOCK |

| [D] Adapter / Shank / Bore Diameter | 30.75 mm |

| [D] Adapter / Shank / Bore Diameter | 1.21 in |

| [AP1MAX] 1st Maximum Cutting Depth | 47.625 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.875 in |

| [L1] Gage Length | 71.5 mm |

| [L1] Gage Length | 2.815 in |

| [CSMS] System Size Machine Side | DL32 |

| [WF] Width of Flat | 28 mm |

| [WF] Width of Flat | 1.102 in |

| [BCH] Corner Chamfer Width | 0.508 mm |

| [BCH] Corner Chamfer Width | .02 in |

| [Z] Number of Flutes | 4 |

| [D1] Effective Cutting Diameter | 31.75 mm |

| [D1] Effective Cutting Diameter | 1.25 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Uses and application

Corner Style: Corner Chamfer

Helical Milling

Ramping: 3°

Side Milling/Shoulder Milling: Square End

Pocketing

Features and benefits

- Versatile modular end mill for steels, stainless steel, cast iron, and high temperature alloys.

- Covers a variety of operations, including dynamic milling, and extreme ramping operations.

- Maximum metal removal, maximum productivity, maximum benefit.

- Asymmetrical divided flutes, variable helix, twisted end face, facteted eccentric relief, and chip gashes within the flutes.

- Centre cutting for plunging and ramping operations.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

| Malzeme grubu | Max Depth |  |  | Diş başına önerilen ilerleme 3D Frezeleme/Profil işleme (A) için (fz=mm/Diş) | ||||||||

| KCPM15–KCSM15 | ||||||||||||

| Kesme hızı | Çap | |||||||||||

| Min. | Başlangıç | Maks. | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||

| P | 0 | 1 x D | 410 | 490 | 580 | IPT | 0.0022 | 0.0026 | 0.003 | 0.0034 | 0.0037 | 0.0041 |

| 1 | 1 x D | 410 | 490 | 580 | IPT | 0.0022 | 0.0026 | 0.003 | 0.0034 | 0.0037 | 0.0041 | |

| 2 | 1 x D | 410 | 490 | 580 | IPT | 0.0022 | 0.0026 | 0.003 | 0.0034 | 0.0037 | 0.0041 | |

| 3 | 1 x D | 360 | 430 | 490 | IPT | 0.0019 | 0.0021 | 0.0026 | 0.0031 | 0.0035 | 0.0037 | |

| 4 | 1 x D | 250 | 360 | 460 | IPT | 0.0016 | 0.0019 | 0.0023 | 0.0027 | 0.003 | 0.0032 | |

| 5 | 0.75 x D | 160 | 230 | 300 | IPT | 0.0015 | 0.0017 | 0.0021 | 0.0024 | 0.0028 | 0.003 | |

| 6 | 0.75 x D | 130 | 180 | 230 | IPT | 0.0012 | 0.0014 | 0.0017 | 0.002 | 0.0022 | 0.0024 | |

| M | 1 | 0.75 x D | 250 | 300 | 330 | IPT | 0.0019 | 0.0021 | 0.0026 | 0.0031 | 0.0035 | 0.0037 |

| 2 | 0.75 x D | 150 | 180 | 220 | IPT | 0.0015 | 0.0017 | 0.0021 | 0.0024 | 0.028 | 0.003 | |

| 3 | 0,5 x D | 130 | 160 | 210 | IPT | 0.0012 | 0.0014 | 0.0017 | 0.002 | 0.0022 | 0.0024 | |

| K | 1 | 1 x D | 360 | 400 | 460 | IPT | 0.0022 | 0.0026 | 0.003 | 0.0034 | 0.0037 | 0.0041 |

| 2 | 1 x D | 330 | 380 | 430 | IPT | 0.0019 | 0.0021 | 0.0026 | 0.0031 | 0.0035 | 0.0037 | |

| 3 | 0.75 x D | 300 | 340 | 390 | IPT | 0.0015 | 0.0017 | 0.0021 | 0.0024 | 0.028 | 0.003 | |

| S | 1 | 0,5 x D | 130 | 190 | 260 | IPT | 0.0019 | 0.0021 | 0.0026 | 0.0031 | 0.0035 | 0.0037 |

| 2 | 0,5 x D | 130 | 180 | 230 | IPT | 0.0015 | 0.0017 | 0.0021 | 0.0024 | 0.028 | 0.003 | |

| 3 | 0,3 x D | 60 | 80 | 110 | IPT | 0.0009 | 0.0011 | 0.0014 | 0.0016 | 0.0019 | 0.002 | |

| 4 | 0,75 x D | 130 | 150 | 160 | IPT | 0.0013 | 0.0016 | 0.002 | 0.0022 | 0.0025 | 0.0028 | |

| H | 1 | 0,75 x D | 230 | 320 | 390 | IPT | 0.0016 | 0.0019 | 0.0023 | 0.0027 | 0.003 | 0.0032 |

| 2 | 0,75 x D | 185 | 255 | 315 | IPT | 0.0011 | 0.0013 | 0.0016 | 0.0019 | 0.0021 | 0.0022 | |

| Malzeme grubu |  |  | KCPM15–KCSM15 | Çap başına önerilen ilerleme oranı (f) | ||||||||||

| Kesme hızı; | D1 | |||||||||||||

| Max Depth | Applicable | Coolant | Min. | Başlangıç | Maks. | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1-1/4 | ||

| P | 0 | 1 x D | Preferred | 360 | 430 | 490 | IPR | 0.0022 | 0.0026 | 0.0033 | 0.0044 | 0.0051 | 0.006 | |

| 1 | 1 x D | Required | 360 | 430 | 490 | IPR | 0.0022 | 0.0026 | 0.0033 | 0.0044 | 0.0051 | 0.006 | ||

| 2 | 1 x D | Required | 360 | 430 | 490 | IPR | 0.0022 | 0.0026 | 0.0033 | 0.0044 | 0.0051 | 0.006 | ||

| 3 | 1 x D | Required | 330 | 350 | 390 | IPR | 0.0017 | 0.0019 | 0.003 | 0.0035 | 0.0041 | 0.0053 | ||

| 4 | 1 x D | Required | 220 | 280 | 330 | IPR | 0.0017 | 0.0019 | 0.003 | 0.0035 | 0.0041 | 0.0053 | ||

| 5 | 0.75 x D | Required | 150 | 160 | 210 | IPR | 0.0011 | 0.0014 | 0.0018 | 0.0024 | 0.0028 | 0.003 | ||

| 6 | 0.75 x D | Required | 130 | 150 | 190 | IPR | 0.0011 | 0.0014 | 0.0018 | 0.0024 | 0.0028 | 0.003 | ||

| M | 1 | 0.75 x D | Required | 190 | 220 | 260 | IPR | 0.0017 | 0.0019 | 0.003 | 0.0035 | 0.0041 | 0.0053 | |

| 2 | 0.75 x D | Required | 130 | 150 | 190 | IPR | 0.0011 | 0.0014 | 0.0018 | 0.0024 | 0.0028 | 0.003 | ||

| 3 | 0.5 x D | Required | 110 | 130 | 160 | IPR | 0.0011 | 0.0014 | 0.0018 | 0.0024 | 0.0028 | 0.003 | ||

| K | 1 | 1 x D | Preferred | 330 | 360 | 390 | IPR | 0.0022 | 0.0026 | 0.0033 | 0.0044 | 0.0051 | 0.006 | |

| 2 | 1 x D | Required | 300 | 330 | 360 | IPR | 0.0017 | 0.0019 | 0.003 | 0.0035 | 0.0041 | 0.0053 | ||

| 3 | 0.75 x D | Required | 250 | 280 | 330 | IPR | 0.0017 | 0.0019 | 0.003 | 0.0035 | 0.0041 | 0.0053 | ||

| S | 1 | 0.5 x D | Required | 100 | 130 | 180 | IPR | 0.0017 | 0.0019 | 0.003 | 0.0035 | 0.0041 | 0.0053 | |

| 2 | 0.5 x D | Required | 100 | 120 | 150 | IPR | 0.0011 | 0.0014 | 0.0018 | 0.0024 | 0.0028 | 0.003 | ||

| 3 | 0.3 x D | Required | 50 | 60 | 90 | IPR | 0.0007 | 0.0009 | 0.0012 | 0.0017 | 0.0019 | 0.0023 | ||

| 4 | 0.75 x D | Required | 100 | 110 | 130 | IPR | 0.0011 | 0.0014 | 0.0018 | 0.0024 | 0.0028 | 0.003 | ||

| H | 1 | 0.75 x D | Required | 190 | 220 | 260 | IPR | 0.0017 | 0.0019 | 0.003 | 0.0035 | 0.0041 | 0.0053 | |

| 2 | ||||||||||||||

| Malzeme grubu |  |  | KCPM15 | Çap başına önerilen ilerleme oranı (f) | ||||||||||

| Kesme hızı; | D1 | |||||||||||||

| Max Depth | Applicable | Coolant | Min. | Başlangıç | Maks. | mm | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | 32,0 | ||

| P | 0 | 1 x D | Preferred | 110 | 130 | 150 | fn | 0,056 | 0,067 | 0,084 | 0,112 | 0,126 | 0,150 | |

| 1 | 1 x D | Required | 110 | 130 | 150 | fn | 0,056 | 0,067 | 0,084 | 0,112 | 0,126 | 0,150 | ||

| 2 | 1 x D | Required | 110 | 130 | 150 | fn | 0,056 | 0,067 | 0,084 | 0,112 | 0,126 | 0,150 | ||

| 3 | 1 x D | Required | 100 | 105 | 120 | fn | 0,042 | 0,049 | 0,075 | 0,088 | 0,105 | 0,135 | ||

| 4 | 1 x D | Required | 70 | 85 | 100 | fn | 0,042 | 0,049 | 0,075 | 0,088 | 0,105 | 0,135 | ||

| 5 | 0,75 x D | Required | 45 | 50 | 65 | fn | 0,028 | 0,035 | 0,046 | 0,060 | 0,070 | 0,076 | ||

| 6 | 0,75 x D | Required | 40 | 45 | 60 | fn | 0,028 | 0,035 | 0,046 | 0,060 | 0,070 | 0,076 | ||

| M | 1 | 0,75 x D | Required | 60 | 70 | 80 | fn | 0,042 | 0,049 | 0,075 | 0,088 | 0,105 | 0,135 | |

| 2 | 0,75 x D | Required | 40 | 45 | 60 | fn | 0,028 | 0,035 | 0,046 | 0,060 | 0,070 | 0,076 | ||

| 3 | 0,5xD | Required | 35 | 40 | 50 | fn | 0,028 | 0,035 | 0,046 | 0,060 | 0,070 | 0,076 | ||

| K | 1 | 1 x D | Preferred | 100 | 110 | 120 | fn | 0,056 | 0,067 | 0,084 | 0,112 | 0,126 | 0,150 | |

| 2 | 1 x D | Required | 90 | 100 | 110 | fn | 0,042 | 0,049 | 0,075 | 0,088 | 0,105 | 0,135 | ||

| 3 | 0,75 x D | Required | 75 | 85 | 100 | fn | 0,042 | 0,049 | 0,075 | 0,088 | 0,105 | 0,135 | ||

| S | 1 | 0,5 x D | Required | 35 | 40 | 55 | fn | 0,042 | 0,049 | 0,075 | 0,088 | 0,105 | 0,135 | |

| 2 | 0,5 x D | Required | 30 | 35 | 45 | fn | 0,028 | 0,035 | 0,046 | 0,060 | 0,070 | 0,076 | ||

| 3 | 0,3 x D | Required | 15 | 20 | 28 | fn | 0,019 | 0,023 | 0,031 | 0,042 | 0,049 | 0,058 | ||

| 4 | 0,75 x D | Required | 30 | 35 | 40 | fn | 0,031 | 0,035 | 0,045 | 0,058 | 0,070 | 0,076 | ||

| H | 1 | 0,75 x D | Required | 60 | 70 | 80 | fn | 0,042 | 0,049 | 0,075 | 0,088 | 0,105 | 0,135 | |

| 2 | 0,75 x D | Required | 50 | 60 | 70 | fn | 0,029 | 0,034 | 0,053 | 0,062 | 0,074 | 0,095 | ||

| Malzeme grubu | Max Depth |  |  | Helisel interpolasyon ve eğimli işleme (rampalama) için önerilen diş başına ilerleme (fz = mm/z) | ||||||||

| KCPM15–KCSM15 | ||||||||||||

| Kesme hızı; | Çap | |||||||||||

| Min. | Başlangıç | Maks. | mm | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | 32,0 | |||

| P | 0 | 1 x D | 125 | 150 | 175 | fz | 0,055 | 0,065 | 0,075 | 0,087 | 0,095 | 0,105 |

| 1 | 1 x D | 125 | 150 | 175 | fz | 0,055 | 0,065 | 0,075 | 0,087 | 0,095 | 0,105 | |

| 2 | 1 x D | 125 | 150 | 175 | fz | 0,055 | 0,065 | 0,075 | 0,087 | 0,095 | 0,105 | |

| 3 | 1 x D | 110 | 130 | 150 | fz | 0,047 | 0,054 | 0,067 | 0,078 | 0,088 | 0,095 | |

| 4 | 1 x D | 75 | 110 | 140 | fz | 0,041 | 0,048 | 0,059 | 0,068 | 0,075 | 0,080 | |

| 5 | 0,75 x D | 50 | 70 | 90 | fz | 0,037 | 0,043 | 0,054 | 0,062 | 0,070 | 0,075 | |

| 6 | 0,75 x D | 40 | 55 | 70 | fz | 0,031 | 0,036 | 0,044 | 0,050 | 0,055 | 0,060 | |

| M | 1 | 0,75 x D | 75 | 90 | 105 | fz | 0,047 | 0,054 | 0,067 | 0,078 | 0,088 | 0,095 |

| 2 | 0,75 x D | 45 | 55 | 70 | fz | 0,037 | 0,043 | 0,054 | 0,062 | 0,070 | 0,075 | |

| 3 | 0,5 x D | 40 | 50 | 65 | fz | 0,031 | 0,036 | 0,044 | 0,050 | 0,055 | 0,060 | |

| K | 1 | 1 x D | 110 | 125 | 140 | fz | 0,055 | 0,065 | 0,075 | 0,087 | 0,095 | 0,105 |

| 2 | 1 x D | 100 | 115 | 130 | fz | 0,047 | 0,054 | 0,067 | 0,078 | 0,088 | 0,095 | |

| 3 | 0,75 x D | 90 | 105 | 120 | fz | 0,037 | 0,043 | 0,054 | 0,062 | 0,070 | 0,075 | |

| S | 1 | 0,5 x D | 40 | 60 | 80 | fz | 0,047 | 0,054 | 0,067 | 0,078 | 0,088 | 0,095 |

| 2 | 0,5 x D | 40 | 55 | 70 | fz | 0,037 | 0,043 | 0,054 | 0,062 | 0,070 | 0,075 | |

| 3 | 0,3 x D | 20 | 25 | 35 | fz | 0,024 | 0,029 | 0,036 | 0,041 | 0,047 | 0,050 | |

| 4 | 0,75 x D | 40 | 45 | 50 | fz | 0,034 | 0,040 | 0,050 | 0,057 | 0,064 | 0,070 | |

| H | 1 | 0,75 x D | 70 | 100 | 120 | fz | 0,041 | 0,048 | 0,059 | 0,068 | 0,075 | 0,080 |

| 2 | 0,75 x D | 60 | 90 | 110 | fz | 0,029 | 0,034 | 0,041 | 0,048 | 0,053 | 0,056 | |

| Malzeme grubu |  |  | Kısa | Orta | Uzun | Kenar frezeleme (A) için önerilen diş başına ilerleme (IPT = inç/diş). Kanal açma (B) için IPT %20 azaltılır. | ||||||||||||||

| A | B | Uygun adaptör | D1 | |||||||||||||||||

| KCPM15 | KCPM15 | KCPM15 | ||||||||||||||||||

| Kesme hızı | Kesme hızı | Kesme hızı | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||||||||

| ap | ae | ap | Min. | Maks. | Min. | Maks. | Min. | Maks. | dec. | .3750 | .5000 | .6250 | .7500 | 1.2500 | 1.2500 | |||||

| P | 0 | 1.5 x D | 0.5 x D | 1 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | 0.0027 | 0.0034 | 0.0039 | 0.0044 | 0.0049 | 0.0049 |

| 1 | 1.5 x D | 0.5 x D | 1 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | 0.0027 | 0.0034 | 0.0039 | 0.0044 | 0.0049 | 0.0049 | |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | 0.0027 | 0.0034 | 0.0039 | 0.0044 | 0.0049 | 0.0049 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | 0.0048 | |

| 4 | 1.5 x D | 0.5 x D | 0.75 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0039 | 0.0040 | |

| 5 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 330 | 170 | – | 281 | 160 | – | 264 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | 0.0039 | |

| 6 | 1.5 x D | 0.5 x D | 0.75 x D | 160 | – | 250 | 136 | – | 213 | 128 | – | 200 | IPT | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | 0.0029 | |

| M | 1 | 1.5 x D | 0.5 x D | 1 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | 0.0048 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | 0.0039 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | 0.0029 | |

| K | 1 | 1.5 x D | 0.5 x D | 1 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | 0.0027 | 0.0034 | 0.0039 | 0.0044 | 0.0049 | 0.0049 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | 0.0048 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | 0.0039 | |

| S | 1 | 1.5 x D | 0.3 x D | 0.3 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | 0.0023 | 0.0029 | 0.0034 | 0.0039 | 0.0045 | 0.0048 |

| 2 | 1.5 x D | 0.3 x D | 0.3 x D | 160 | – | 260 | 128 | – | 208 | 96 | – | 156 | IPT | 0.0018 | 0.0023 | 0.0027 | 0.0031 | 0.0036 | 0.0039 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | 0.0012 | 0.0015 | 0.0018 | 0.0021 | 0.0024 | 0.0026 | |

| 4 | 1.5 x D | 0.5 x D | 1 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | 0.0017 | 0.0021 | 0.0025 | 0.0028 | 0.0033 | 0.0036 | |

| H | 1 | 1.5 x D | 0.5 x D | 0.75 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | 0.0020 | 0.0026 | 0.0030 | 0.0034 | 0.0039 | 0.0040 |

| 2 | 1.5 x D | 0.2 x D | 0.5 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | 0.0015 | 0.0019 | 0.0022 | 0.0025 | 0.0028 | 0.0029 | |

| 1.5xD | 0.5XD | 1xD | 0 | 150 | - | 200 | 135 | - | 180 | 135 | - | 180 | Fz | 0.072 | 0.083 | 0.101 | 0.108 | 0.114 | 0.124 | 0.125 | |

| 1.5xD | 0.5XD | 1xD | 0 | 150 | - | 200 | 135 | - | 180 | 135 | - | 180 | Fz | 0.072 | 0.083 | 0.101 | 0.108 | 0.114 | 0.124 | 0.125 | |

| 1.5xD | 0.5XD | 1xD | 0 | 140 | - | 190 | 126 | - | 171 | 126 | - | 171 | Fz | 0.072 | 0.083 | 0.101 | 0.108 | 0.114 | 0.124 | 0.125 | |

| 1.5xD | 0.5XD | 1xD | 0 | 120 | - | 160 | 108 | - | 144 | 108 | - | 144 | Fz | 0.061 | 0.070 | 0.087 | 0.095 | 0.101 | 0.114 | 0.123 | |

| 1.5xD | 0.5XD | 0.75xD | 0 | 90 | - | 150 | 81 | - | 135 | 81 | - | 135 | Fz | 0.054 | 0.062 | 0.077 | 0.083 | 0.088 | 0.098 | 0.102 | |

| 1.5xD | 0.5XD | 1xD | 0 | 60 | - | 100 | 51 | - | 85 | 48 | - | 80 | Fz | 0.048 | 0.056 | 0.070 | 0.076 | 0.081 | 0.091 | 0.099 | |

| 1.5xD | 0.5XD | 0.75xD | 0 | 50 | - | 75 | 43 | - | 64 | 40 | - | 60 | Fz | 0.040 | 0.047 | 0.057 | 0.061 | 0.065 | 0.071 | 0.073 | |

| 1.5xD | 0.5XD | 1xD | 0 | 90 | - | 115 | 72 | - | 92 | 63 | - | 81 | Fz | 0.061 | 0.070 | 0.087 | 0.095 | 0.101 | 0.114 | 0.123 | |

| 1.5xD | 0.5XD | 1xD | 0 | 60 | - | 80 | 48 | - | 64 | 42 | - | 56 | Fz | 0.048 | 0.056 | 0.070 | 0.076 | 0.081 | 0.091 | 0.099 | |

| 1.5xD | 0.5XD | 1xD | 0 | 60 | - | 70 | 48 | - | 56 | 42 | - | 49 | Fz | 0.040 | 0.047 | 0.057 | 0.061 | 0.065 | 0.071 | 0.073 | |

| 1.5xD | 0.5XD | 1xD | 0 | 120 | - | 150 | 108 | - | 135 | 108 | - | 135 | Fz | 0.072 | 0.083 | 0.101 | 0.108 | 0.114 | 0.124 | 0.125 | |

| 1.5xD | 0.5XD | 1xD | 0 | 110 | - | 140 | 99 | - | 126 | 99 | - | 126 | Fz | 0.061 | 0.070 | 0.087 | 0.095 | 0.101 | 0.114 | 0.123 | |

| 1.5xD | 0.5XD | 1xD | 0 | 110 | - | 130 | 99 | - | 117 | 99 | - | 117 | Fz | 0.048 | 0.056 | 0.070 | 0.076 | 0.081 | 0.091 | 0.099 | |

| 1.5xD | 0.3XD | 0.3XD | 0 | 50 | - | 90 | 40 | - | 72 | 30 | - | 54 | Fz | 0.061 | 0.070 | 0.087 | 0.095 | 0.101 | 0.114 | 0.123 | |

| 1.5xD | 0.3XD | 0.3XD | 0 | 50 | - | 80 | 40 | - | 64 | 30 | - | 48 | Fz | 0.048 | 0.056 | 0.070 | 0.076 | 0.081 | 0.091 | 0.099 | |

| 1.5xD | 0.3XD | 0.3XD | 0 | 50 | - | 80 | 40 | - | 64 | 30 | - | 48 | Fz | 0.032 | 0.037 | 0.046 | 0.050 | 0.054 | 0.061 | 0.067 | |

| 1.5xD | 0.5XD | 1xD | 0 | 50 | - | 60 | 40 | - | 48 | 30 | - | 36 | Fz | 0.045 | 0.052 | 0.064 | 0.069 | 0.074 | 0.084 | 0.090 | |

| 1.5xD | 0.5XD | 0.75xD | 0 | 80 | - | 140 | 64 | - | 112 | 48 | - | 84 | Fz | 0.054 | 0.062 | 0.077 | 0.083 | 0.088 | 0.098 | 0.102 | |

| 1.5xD | 0.2XD | 0.5xD | 0 | 70 | - | 120 | 56 | - | 96 | 42 | - | 72 | Fz | 0.040 | 0.047 | 0.057 | 0.061 | 0.065 | 0.071 | 0.073 |

I have read and accepted the Terms & Conditions of use