Product Similar To:

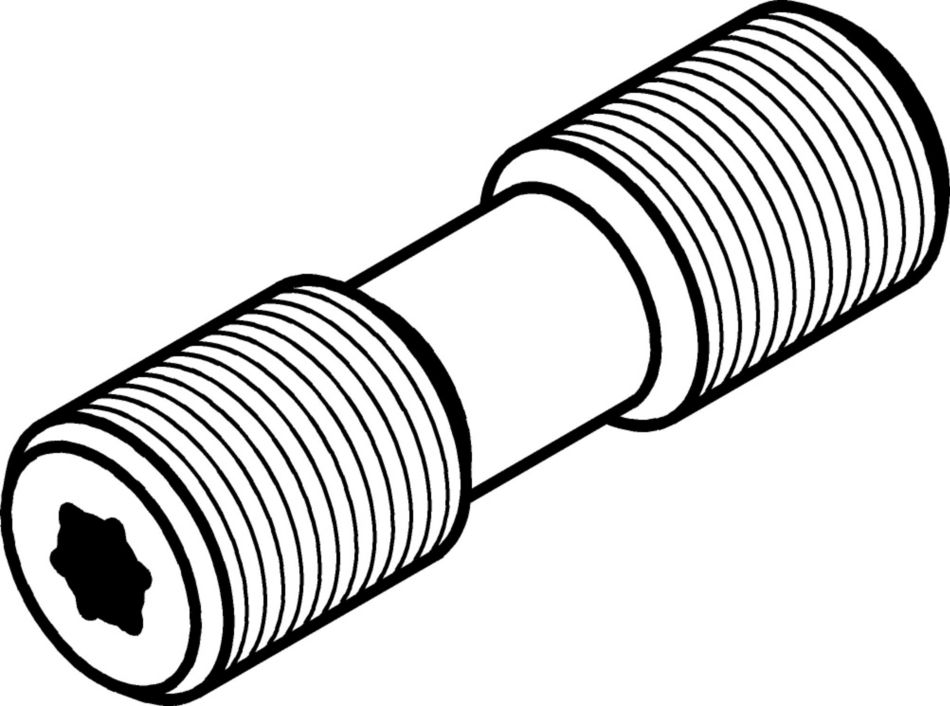

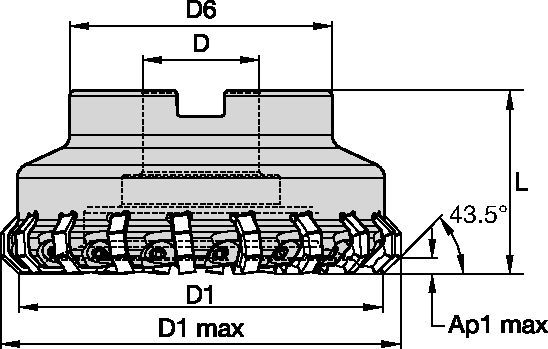

Mill 16™ • Shell Mill • Wedge Clamping • Fine Pitch • Metric

Face Mill • Cast Iron Machining

Material Number6001977

ISO Catalog IDMILL16D160Z22ON08WANSI Catalog IDMILL16D160Z22ON08W

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

Face Milling

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 6001977 |

| ISO Catalog ID | MILL16D160Z22ON08W |

| ANSI Catalog ID | MILL16D160Z22ON08W |

| [D1] Effective Cutting Diameter | 160 mm |

| [D1] Effective Cutting Diameter | 6.299 in |

| [D1MAX] Maximum Cutting Diameter | 172.55 mm |

| [D1MAX] Maximum Cutting Diameter | 6.793 in |

| [D] Adapter / Shank / Bore Diameter | 40 mm |

| [D] Adapter / Shank / Bore Diameter | 1.575 in |

| [D6] Hub Diameter | 90 mm |

| [D6] Hub Diameter | 3.543 in |

| [L] Overall Length | 63 mm |

| [L] Overall Length | 2.48 in |

| [AP1MAX] 1st Maximum Cutting Depth | 5.5 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .215 in |

| Number of Inserts | 22 |

| Weight Kilograms | 4.11 |

| Max RPM | 5200 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

Uses and application

Face Milling

Milling - Side and Face

Features and benefits

- Milling cutters for cast iron and compacted graphite iron (CGI) machining.

- Ideal for roughing of engine heads and blocks, housings, gear boxes, etc.

- Insert pocket numbering system.

- High feed rate capability to boost productivity and reduce cycle time.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

Insert Selection Guide

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | (Sert geometri) | ||||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..LE | KC514M | .S..GP | KC514M | .S..HB | KC514M |

| K3 | .E..LE | KCK20 | .S..GP | KCK20 | .S..HB | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

Feeds

Recommended Starting Feeds [mm]

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .E..LE | 0,23 | 0,66 | 1,16 | 0,17 | 0,47 | 0,83 | 0,13 | 0,35 | 0,62 | 0,11 | 0,31 | 0,54 | 0,10 | 0,28 | 0,49 | .E..LE |

| .S..GP | 0,33 | 0,74 | 1,26 | 0,24 | 0,53 | 0,90 | 0,18 | 0,40 | 0,67 | 0,16 | 0,35 | 0,59 | 0,14 | 0,32 | 0,54 | .S..GP |

| .S..HB | 0,33 | 0,84 | 1,35 | 0,24 | 0,60 | 0,97 | 0,18 | 0,45 | 0,72 | 0,16 | 0,39 | 0,63 | 0,14 | 0,36 | 0,57 | .S..HB |

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

Recommended Starting Feeds [IPT]

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| .E..LE | .009 | .026 | .046 | .007 | .019 | .033 | .005 | .014 | .025 | .004 | .012 | .022 | .004 | .011 | .020 | .E..LE |

| .S..GP | .013 | .029 | .049 | .009 | .021 | .035 | .007 | .016 | .026 | .006 | .014 | .023 | .006 | .012 | .021 | .S..GP |

| .S..HB | .013 | .033 | .053 | .009 | .024 | .038 | .007 | .018 | .028 | .006 | .015 | .025 | .006 | .014 | .023 | .S..HB |

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

Speeds

Recommended Starting Speeds [m/min]

| Malzeme grubu | KC514M | KCK15 | KCK20 | KCPK30 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 290 | 190 | 135 | 330 | 220 | 150 | 330 | 220 | 150 | 295 | 265 | 240 |

| 2 | 225 | 160 | 115 | 250 | 180 | 125 | 250 | 180 | 125 | 235 | 210 | 190 | |

| 3 | 190 | 135 | 110 | 220 | 150 | 120 | 220 | 150 | 120 | 195 | 175 | 160 | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| Malzeme grubu | KC514M | KCK15 | KCK20 | KCPK30 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 955 | 625 | 495 | 1085 | 725 | 495 | 1085 | 725 | 495 | 970 | 870 | 785 |

| 2 | 745 | 525 | 410 | 820 | 595 | 410 | 820 | 595 | 410 | 770 | 690 | 625 | |

| 3 | 625 | 445 | 395 | 725 | 495 | 395 | 725 | 495 | 395 | 640 | 575 | 525 | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

I have read and accepted the Terms & Conditions of use