Product Similar To:

SHD_301HA/SHD_501HA • 3 x D/5 x D • Metric

Stellram® HardCore® Drill • Without Coolant

Material Number5654207

ISO Catalog IDSHD0397/0.156/501HAANSI Catalog IDSHD0397/0.156/501HA

Drilling

DIN number 6535

DIN number 6537

Flood Coolant: Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5654207 |

| ISO Catalog ID | SHD0397/0.156/501HA |

| ANSI Catalog ID | SHD0397/0.156/501HA |

| Grade | HCT600 |

| Engineering Tool Family | SHD_501_H_ |

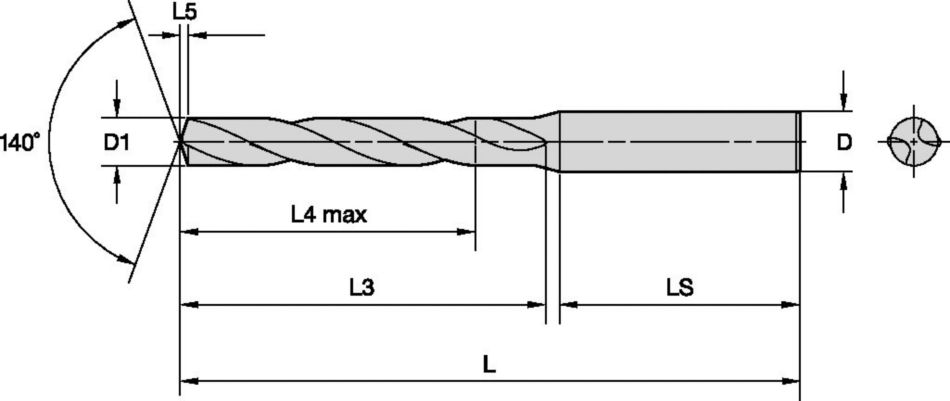

| [D1] Drill Diameter M | 3.97 mm |

| [D1] Drill Diameter M | .1563 in |

| [L5] Drill Point Length | 0.722 mm |

| [L5] Drill Point Length | .0284 in |

| [LS] Shank Length | 36 mm |

| [LS] Shank Length | 1.417 in |

| [D] Adapter / Shank / Bore Diameter | 6 mm |

| [D] Adapter / Shank / Bore Diameter | .236 in |

| [L] Overall Length | 74 mm |

| [L] Overall Length | 2.913 in |

| [L3] Flute Length | 36 mm |

| [L3] Flute Length | 1.417 in |

| [L4] Maximum Drilling Depth | 29 mm |

| [L4] Maximum Drilling Depth | 1.142 in |

Uses and application

Drilling

DIN number 6535

DIN number 6537

Flood Coolant: Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Grades

HCT600

Composition: PVD TiAlN coated dual-layer fine-grain carbide.

Application: Applicable in steel, cast iron, and hardened materials. This grade perfectly combines a tough substrate in the core to improve toughness and shock resistance at the drill center where circumferential speeds are low with a harder substrate as case material for optimized wear resistance towards the cutting corner where circumferential speeds are high.

Features and benefits

- Stellram® HardCore® drill for tough materials.

- Material-specific SC drill made of dual grade.

- Outer carbide grade for high speeds with high wear-resistant properties.

- Core carbide grade for low speeds with excellent toughness and shock-resistant properties.

- Operate this drill with flood coolant in P3 and P4 steels with a tensile strength up to 1400 MPa and H1 and H2 hardened materials with hardness up to 55 HRC.

- Accurate ground edge preparation enables reduced bur formation.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use