Product Similar To :

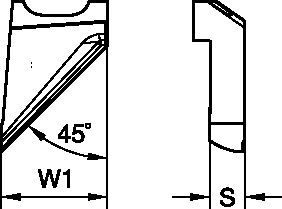

SEFAS Chamfering Inserts • R021 • 41°/45°

SEFAS™ Chamfering Inserts

Material Number1208635

ISO Catalog ID3.42805R001ANSI Catalog ID3.42805R001

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1208635 |

| ISO Catalog ID | 3.42805R001 |

| ANSI Catalog ID | 3.42805R001 |

| Grade | KMF |

| [EPSILONR] Profile Angle | 45 |

| [S] Insert Thickness | 2.83 mm |

| [S] Insert Thickness | 0.1114 in |

| [W1] Insert Width | 8 mm |

| [W1] Insert Width | 0.315 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

Grades

KMF

Uncoated carbide grade. KMF is a fine-grain substrate for machining of high-temp alloys and non-ferrous materials and cast irons.

Features and benefits

- Use RO21 SEFAS Chamfering Inserts when using KenTIP or KSEM Drills.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Dimension

| K210, K254, K284 | K211, K222, K255, K285, K411 | K212, K256 | unalloyed and low-alloy steel, unalloyed and alloy steel, and cast iron, high-alloy steel and stainless steel | ||||||

| drill diameter D1 | TBmin | TBmax | TBmin | TBmax | TBmin | TBmax | TS100 | TS80 | TSmax |

| .156-.188 | .236 | .866 | .472 | 1.102 | .866 | 1.102 | .047 | .071 | .098 |

| .354 | 1.024 | .709 | 1.378 | 1.220 | 1.890 | .059 | .087 | .118 | |

| .433 | 1.102 | .906 | 1.575 | 1.654 | 2.323 | .079 | .118 | .157 | |

| .433 | 1.102 | .906 | 1.575 | 1.654 | 2.323 | .098 | .157 | .197 | |

| .512 | 1.142 | 1.063 | 1.693 | 1.929 | 2.559 | .118 | .197 | .236 | |

| .551 | 1.260 | 1.142 | 1.850 | 2.008 | 2.717 | .138 | .197 | .276 | |

| .591 | 1.378 | 1.220 | 2.008 | 2.205 | 2.992 | .157 | .236 | .315 | |

| .827 | 1.417 | 1.496 | 2.087 | 2.717 | 3.307 | .157 | .236 | .315 | |

| .866 | 1.575 | 1.575 | 2.283 | 3.071 | 3.780 | .157 | .236 | .315 | |

| 1.299 | 1.850 | 2.087 | 2.638 | 3.740 | 4.291 | .157 | .236 | .315 | |

| 1.378 | 2.008 | 2.126 | 2.756 | 4.055 | 4.685 | .157 | .236 | .315 | |

| 1.552 | 2.181 | 2.260 | 2.890 | 4.386 | 5.016 | .157 | .236 | .315 | |

| 1.702 | 2.293 | 2.726 | 3.317 | 4.694 | 5.285 | .157 | .236 | .315 | |

| 1.735 | 2.404 | 2.876 | 3.546 | 4.884 | 5.554 | .157 | .236 | .315 | |

| 1.846 | 2.515 | 3.067 | 3.736 | 5.193 | 5.862 | .157 | .236 | .315 | |

| B210A, B221A, B224A, B254A, B284A, B291A, B707A, B966A, B976A | B211A, B222A, B225A, B285A, B292A, B411A B708A, B977A | B212A, B256A B709A, B978A | unalloyed and low-alloy steel unalloyed and alloy steel, and cast iron high alloy steel and stainless steel | ||||||

| drill diameter D1 | TBmin | TBmax | TBmin | TBmax | TBmin | TBmax | TS100 | TS80 | TSmax |

| 4,0-4,7 | 4 | 17 | 12 | 29 | 20 | 36 | 1,2 | 1,8 | 2,5 |

| 4 | 20 | 20 | 35 | 27 | 43 | 1,5 | 2,2 | 3,0 | |

| 11 | 24 | 23 | 40 | 32 | 49 | 2 | 3,0 | 4,0 | |

| 11 | 28 | 23 | 40 | 42 | 59 | 2,5 | 4,0 | 5,0 | |

| 13 | 29 | 27 | 43 | 46 | 62 | 2,5 | 4,0 | 5,0 | |

| 15 | 35 | 31 | 51 | 54 | 74 | 3,5 | 5,0 | 7,0 | |

| 21 | 36 | 38 | 53 | 69 | 84 | 4,0 | 6,0 | 8,0 | |

| 22 | 40 | 40 | 58 | 78 | 96 | 4,0 | 6,0 | 8,0 | |

| 31 | 45 | 51 | 65 | 93 | 107 | 4,0 | 6,0 | 8,0 | |

| 34 | 50 | 56 | 72 | 103 | 119 | 4,0 | 6,0 | 8,0 | |

I have read and accepted the Terms & Conditions of use