Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Sign Out

Item(s) successfully added to cart

View Cart

View Cart

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Holemaking

- /

- Precision Hole Finishing

- /

- Reaming

- /

- Solid Reaming

- /

- RMS with Helical Flutes and Internal Coolant

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

RMS with Helical Flutes and Internal Coolant

RMS™ Solid Carbide Reaming

Features and benefits

- For hole tolerance H7.

- Intermediate sizes ground to achieve IT7 hole tolerance class available.

- Starting with Ø .393″ (10mm) in IT6 hole tolerance available.

Uses and application

Reaming: Through Hole

Reaming: Through & Cross Holes

Reaming - Through Coolant

Shank - Cylindrical Plain

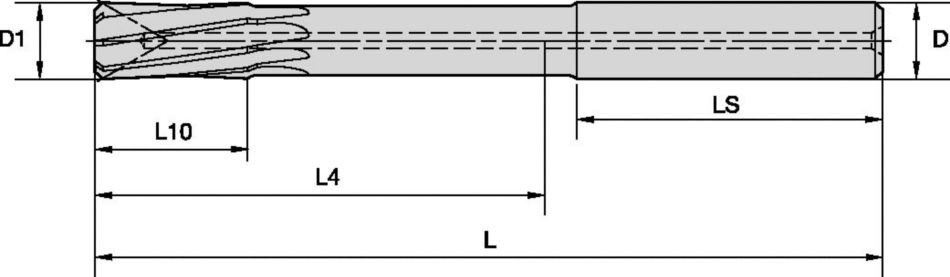

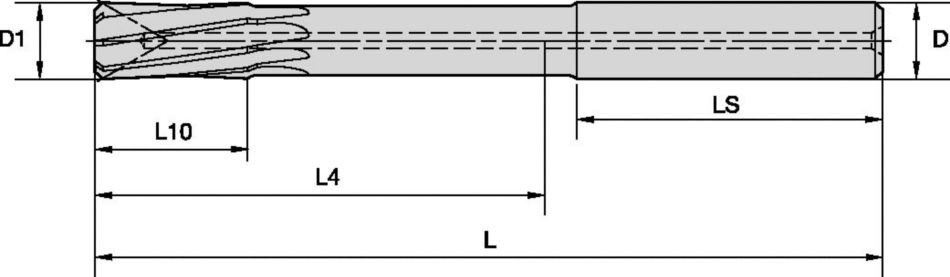

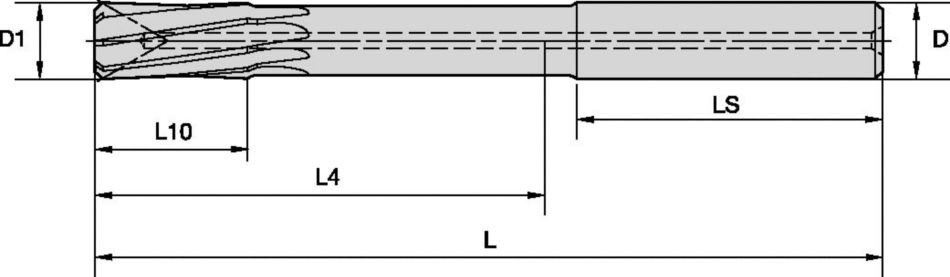

Dimensions for Engineered-Solution Reamers

| D1 min | D1 max | D | L | L4 | L10 | LS | ||||||||

| mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | Z |

| 14,000 | 0.5512 | 15,999 | 0.6299 | 16 | 0.630 | 147,4 | 5.80 | 92,4 | 3.64 | 7,5 | 0.30 | 49 | 1.93 | 6 |

| 16,000 | 0.6299 | 17,999 | 0.7086 | 20 | 0.787 | 159,4 | 6.28 | 102,4 | 4.03 | 7,5 | 0.30 | 51 | 2.01 | 6 |

| 18,000 | 0.7087 | 20,000 | 0.7874 | 20 | 0.787 | 173,4 | 6.83 | 116,4 | 4.58 | 7,5 | 0.30 | 51 | 2.01 | 6 |

| 20,001 | 0.7874 | 22,499 | 0.8858 | 20 | 0.787 | 202,4 | 7.97 | 145,4 | 5.72 | 7,5 | 0.30 | 51 | 2.01 | 6 |

| 22,500 | 0.8858 | 24,999 | 0.9842 | 20 | 0.787 | 212,4 | 8.36 | 155,4 | 6.12 | 7,5 | 0.30 | 51 | 2.01 | 6 |

| 25,000 | 0.9843 | 27,499 | 1.0826 | 25 | 0.984 | 232,4 | 9.15 | 169,4 | 6.67 | 7,5 | 0.30 | 57 | 2.24 | 8 |

| 27,500 | 1.0827 | 29,999 | 1.1811 | 25 | 0.984 | 242,4 | 9.54 | 179,4 | 7.06 | 7,5 | 0.30 | 57 | 2.24 | 8 |

| 30,000 | 1.1811 | 32,499 | 1.2795 | 25 | 0.984 | 272,4 | 10.72 | 209,4 | 8.24 | 7,5 | 0.30 | 57 | 2.24 | 8 |

| 32,500 | 1.2795 | 34,999 | 1.3779 | 32 | 1.260 | 272,4 | 10.72 | 205,4 | 8.09 | 7,5 | 0.30 | 61 | 2.40 | 8 |

| 35,000 | 1.3780 | 37,499 | 1.4763 | 32 | 1.260 | 272,4 | 10.72 | 205,4 | 8.09 | 7,5 | 0.30 | 61 | 2.40 | 8 |

| 37,500 | 1.4764 | 39,999 | 1.5748 | 32 | 1.260 | 272,4 | 10.72 | 205,4 | 8.09 | 7,5 | 0.30 | 61 | 2.40 | 8 |

| 40,000 | 1.5748 | 42,500 | 1.6732 | 32 | 1.260 | 272,4 | 10.72 | 205,4 | 8.09 | 7,5 | 0.30 | 61 | 2.40 | 8 |

| Material |  |  |  |  | ||||||||||

| straight flute | helical flute | |||||||||||||

| K605 | KC6305 | Inch | ||||||||||||

| Cutting Speed | Cutting Speed | Recommended Feed Rate per Tooth | ||||||||||||

| Range | Range | Tool Diameter | .164–.281 | .282–.378 | .378–.551 | |||||||||

| Min | Starting Value | Max | Min | Starting Value | Max | Feed/Tooth | Min | Max | Min | Max | Min | Max | ||

| P | 1 | 131 | 197 | 230 | 295 | 394 | 508 | inch/z | .002 | .004 | .002 | .005 | .002 | .006 |

| 2 | 131 | 197 | 230 | 295 | 394 | 508 | inch/z | .002 | .004 | .002 | .005 | .002 | .006 | |

| 3 | 115 | 164 | 197 | 246 | 328 | 426 | inch/z | .002 | .004 | .002 | .005 | .002 | .006 | |

| 4 | 82 | 131 | 148 | 197 | 262 | 344 | inch/z | .002 | .004 | .002 | .005 | .002 | .006 | |

| 5 | 49 | 66 | 82 | 98 | 131 | 180 | inch/z | .002 | .003 | .002 | .004 | .002 | .005 | |

| 6 | 49 | 66 | 82 | 98 | 131 | 180 | inch/z | .002 | .003 | .002 | .004 | .002 | .005 | |

| M | 1 | 26 | 33 | 49 | 49 | 66 | 92 | inch/z | .002 | .003 | .002 | .004 | .002 | .004 |

| 2 | 26 | 33 | 49 | 49 | 66 | 92 | inch/z | .002 | .003 | .002 | .004 | .002 | .004 | |

| 3 | 26 | 33 | 49 | 49 | 66 | 92 | inch/z | .002 | .003 | .002 | .004 | .002 | .004 | |

| K | 1 | 115 | 164 | 197 | 246 | 328 | 426 | inch/z | .002 | .006 | .002 | .007 | .002 | .008 |

| 2 | 82 | 131 | 164 | 197 | 295 | 361 | inch/z | .002 | .006 | .002 | .006 | .002 | .007 | |

| 3 | 66 | 98 | 148 | 197 | 262 | 344 | inch/z | .002 | .005 | .002 | .006 | .002 | .006 | |

| N | 1 | 361 | 492 | 640 | – | – | – | inch/z | .002 | .006 | .002 | .007 | .002 | .008 |

| 2 | 361 | 492 | 640 | – | – | – | inch/z | .002 | .006 | .002 | .007 | .002 | .008 | |

| 3 | 361 | 492 | 640 | – | – | – | inch/z | .002 | .006 | .002 | .007 | .002 | .008 | |

| 4 | 361 | 492 | 640 | – | – | – | inch/z | .002 | .006 | .002 | .007 | .002 | .008 | |

| 5 | 344 | 459 | 590 | – | – | – | inch/z | .002 | .006 | .002 | .007 | .002 | .008 | |

| S | 1 | 26 | 33 | 49 | 49 | 66 | 92 | inch/z | .002 | .003 | .002 | .004 | .002 | .005 |

| 2 | 26 | 33 | 49 | 50 | 66 | 92 | inch/z | .002 | .003 | .002 | .004 | .002 | .005 | |

| 3 | 49 | 66 | 98 | 66 | 98 | 131 | inch/z | .002 | .004 | .002 | .005 | .002 | .006 | |

| 4 | 49 | 66 | 98 | 66 | 98 | 131 | inch/z | .002 | .004 | .002 | .005 | .002 | .006 | |

| Material |  |  |  |  | ||||||||||

| straight flute | helical flute | |||||||||||||

| K605 | KC6305 | Metric | ||||||||||||

| Cutting Speed | Recommended Feed Rate per Tooth | |||||||||||||

| Range | Tool Diameter | 4,16–7,15mm | 7,16–9,59mm | 9,60–14,00mm | ||||||||||

| Min | Starting Value | Max | Min | Starting Value | Max | Feed/Tooth | Min | Max | Min | Max | Min | Max | ||

| P | 1 | 40 | 60 | 70 | 90 | 120 | 155 | mm/z | 0,05 | 0,10 | 0,05 | 0,12 | 0,05 | 0,15 |

| 2 | 40 | 60 | 70 | 90 | 120 | 155 | mm/z | 0,05 | 0,10 | 0,05 | 0,12 | 0,05 | 0,15 | |

| 3 | 35 | 50 | 60 | 75 | 100 | 130 | mm/z | 0,05 | 0,10 | 0,05 | 0,12 | 0,05 | 0,15 | |

| 4 | 25 | 40 | 45 | 60 | 80 | 105 | mm/z | 0,05 | 0,10 | 0,05 | 0,12 | 0,05 | 0,15 | |

| 5 | 15 | 20 | 25 | 30 | 40 | 55 | mm/z | 0,04 | 0,08 | 0,04 | 0,10 | 0,04 | 0,12 | |

| 6 | 15 | 20 | 25 | 30 | 40 | 55 | mm/z | 0,04 | 0,08 | 0,04 | 0,10 | 0,04 | 0,12 | |

| M | 1 | 8 | 10 | 15 | 15 | 20 | 28 | mm/z | 0,04 | 0,08 | 0,04 | 0,09 | 0,04 | 0,10 |

| 2 | 8 | 10 | 15 | 15 | 20 | 28 | mm/z | 0,04 | 0,08 | 0,04 | 0,09 | 0,04 | 0,10 | |

| 3 | 8 | 10 | 15 | 15 | 20 | 28 | mm/z | 0,04 | 0,08 | 0,04 | 0,09 | 0,04 | 0,10 | |

| K | 1 | 35 | 50 | 60 | 75 | 100 | 130 | mm/z | 0,05 | 0,16 | 0,05 | 0,18 | 0,05 | 0,20 |

| 2 | 25 | 40 | 50 | 60 | 90 | 110 | mm/z | 0,05 | 0,14 | 0,05 | 0,16 | 0,05 | 0,18 | |

| 3 | 20 | 30 | 45 | 60 | 80 | 105 | mm/z | 0,05 | 0,12 | 0,05 | 0,14 | 0,05 | 0,16 | |

| N | 1 | 110 | 150 | 195 | – | – | – | mm/z | 0,06 | 0,16 | 0,06 | 0,18 | 0,06 | 0,20 |

| 2 | 110 | 150 | 195 | – | – | – | mm/z | 0,06 | 0,16 | 0,06 | 0,18 | 0,06 | 0,20 | |

| 3 | 110 | 150 | 195 | – | – | – | mm/z | 0,06 | 0,16 | 0,06 | 0,18 | 0,06 | 0,20 | |

| 4 | 110 | 150 | 195 | – | – | – | mm/z | 0,06 | 0,16 | 0,06 | 0,18 | 0,06 | 0,20 | |

| 5 | 105 | 140 | 180 | – | – | – | mm/z | 0,06 | 0,16 | 0,06 | 0,18 | 0,06 | 0,20 | |

| S | 1 | 8 | 10 | 15 | 15 | 20 | 28 | mm/z | 0,04 | 0,08 | 0,04 | 0,10 | 0,04 | 0,12 |

| 2 | 8 | 10 | 15 | 15 | 20 | 28 | mm/z | 0,04 | 0,08 | 0,04 | 0,10 | 0,04 | 0,12 | |

| 3 | 15 | 20 | 30 | 20 | 30 | 40 | mm/z | 0,05 | 0,10 | 0,05 | 0,12 | 0,05 | 0,15 | |

| 4 | 15 | 20 | 30 | 20 | 30 | 40 | mm/z | 0,05 | 0,10 | 0,05 | 0,12 | 0,05 | 0,15 | |

|  |  |  | |||||||||||

| straight flute | helical flute | |||||||||||||

| K605 | KC6305 | Metric | ||||||||||||

| Cutting Speed | Recommended Feed Rate per Tooth | |||||||||||||

| Range | Tool Diameter | 4,16–7,15 | 7,16–9,59 | 9,60–14,00 | ||||||||||

| Material | Min | Starting Value | Max | Min | Starting Value | Max | Feed/Tooth | Min | Max | Min | Max | Min | Max | |

| P | 1 | 40 | 60 | 70 | 90 | 120 | 155 | mm/z | 0,05 | 0,10 | 0,05 | 0,12 | 0,05 | 0,15 |

| 2 | 40 | 60 | 70 | 90 | 120 | 155 | mm/z | 0,05 | 0,10 | 0,05 | 0,12 | 0,05 | 0,15 | |

| 3 | 35 | 50 | 60 | 75 | 100 | 130 | mm/z | 0,05 | 0,10 | 0,05 | 0,12 | 0,05 | 0,15 | |

| 4 | 25 | 40 | 45 | 60 | 80 | 105 | mm/z | 0,05 | 0,10 | 0,05 | 0,12 | 0,05 | 0,15 | |

| 5 | 15 | 20 | 25 | 30 | 40 | 55 | mm/z | 0,04 | 0,08 | 0,04 | 0,10 | 0,04 | 0,12 | |

| 6 | 15 | 20 | 25 | 30 | 40 | 55 | mm/z | 0,04 | 0,08 | 0,04 | 0,10 | 0,04 | 0,12 | |

| M | 1 | 8 | 10 | 15 | 15 | 20 | 28 | mm/z | 0,04 | 0,08 | 0,04 | 0,09 | 0,04 | 0,10 |

| 2 | 8 | 10 | 15 | 15 | 20 | 28 | mm/z | 0,04 | 0,08 | 0,04 | 0,09 | 0,04 | 0,10 | |

| 3 | 8 | 10 | 15 | 15 | 20 | 28 | mm/z | 0,04 | 0,08 | 0,04 | 0,09 | 0,04 | 0,10 | |

| K | 1 | 35 | 50 | 60 | 75 | 100 | 130 | mm/z | 0,05 | 0,16 | 0,05 | 0,18 | 0,05 | 0,20 |

| 2 | 25 | 40 | 50 | 60 | 90 | 110 | mm/z | 0,05 | 0,14 | 0,05 | 0,16 | 0,05 | 0,18 | |

| 3 | 20 | 30 | 45 | 60 | 80 | 105 | mm/z | 0,05 | 0,12 | 0,05 | 0,14 | 0,05 | 0,16 | |

| N | 1 | 110 | 150 | 195 | – | – | – | mm/z | 0,06 | 0,16 | 0,06 | 0,18 | 0,06 | 0,20 |

| 2 | 110 | 150 | 195 | – | – | – | mm/z | 0,06 | 0,16 | 0,06 | 0,18 | 0,06 | 0,20 | |

| 3 | 110 | 150 | 195 | – | – | – | mm/z | 0,06 | 0,16 | 0,06 | 0,18 | 0,06 | 0,20 | |

| 4 | 110 | 150 | 195 | – | – | – | mm/z | 0,06 | 0,16 | 0,06 | 0,18 | 0,06 | 0,20 | |

| 5 | 105 | 140 | 180 | – | – | – | mm/z | 0,06 | 0,16 | 0,06 | 0,18 | 0,06 | 0,20 | |

| S | 1 | 8 | 10 | 15 | 15 | 20 | 28 | mm/z | 0,04 | 0,08 | 0,04 | 0,10 | 0,04 | 0,12 |

| 2 | 8 | 10 | 15 | 15 | 20 | 28 | mm/z | 0,04 | 0,08 | 0,04 | 0,10 | 0,04 | 0,12 | |

| 3 | 15 | 20 | 30 | 20 | 30 | 40 | mm/z | 0,05 | 0,10 | 0,05 | 0,12 | 0,05 | 0,15 | |

| 4 | 15 | 20 | 30 | 20 | 30 | 40 | mm/z | 0,05 | 0,10 | 0,05 | 0,12 | 0,05 | 0,15 | |

| Recommended Reaming Allowance in Diameter | ||||||

| Tool Diameter (mm) | 4,000 | 7,001 | 10,001 | |||

| 2 x ap | min | max | min | max | min | max |

| mm | 0,20 | 0,30 | 0,20 | 0,30 | 0,20 | 0,40 |

| Material | Cutting Speed | Recommended feed per tooth (fz = mm/th) | |||||||||

| Range | |||||||||||

| Min | Starting Value | Max | Tool Diameter | 4,000 | 7,001 | 10,001 | |||||

| Feed/Tooth | Min | Max | Min | Max | Min | Max | |||||

| P | 1 | 90 | 130 | 160 | mm/z | 0,06 | 0,12 | 0,08 | 0,15 | 0,08 | 0,20 |

| 2 | 90 | 130 | 160 | mm/z | 0,06 | 0,12 | 0,08 | 0,15 | 0,08 | 0,20 | |

| 3 | 90 | 130 | 160 | mm/z | 0,06 | 0,12 | 0,08 | 0,15 | 0,08 | 0,20 | |

| 4 | 80 | 120 | 160 | mm/z | 0,06 | 0,12 | 0,08 | 0,15 | 0,08 | 0,20 | |

| 5 | 20 | 40 | 60 | mm/z | 0,06 | 0,12 | 0,08 | 0,15 | 0,08 | 0,15 | |

| 6 | 20 | 40 | 60 | mm/z | 0,06 | 0,12 | 0,08 | 0,15 | 0,08 | 0,15 | |

| M | 1 | 20 | 40 | 50 | mm/z | 0,08 | 0,12 | 0,08 | 0,15 | 0,08 | 0,15 |

| 2 | 20 | 40 | 50 | mm/z | 0,08 | 0,12 | 0,08 | 0,15 | 0,08 | 0,15 | |

| 3 | 20 | 40 | 50 | mm/z | 0,08 | 0,12 | 0,08 | 0,15 | 0,08 | 0,15 | |

| K | 1 | 80 | 160 | 240 | mm/z | 0,06 | 0,15 | 0,08 | 0,20 | 0,08 | 0,20 |

| 2 | 80 | 140 | 200 | mm/z | 0,06 | 0,15 | 0,08 | 0,20 | 0,08 | 0,20 | |

| 3 | 60 | 90 | 120 | mm/z | 0,06 | 0,15 | 0,08 | 0,15 | 0,08 | 0,15 | |

| S | 1 | 15 | 20 | 30 | mm/z | 0,06 | 0,12 | 0,06 | 0,15 | 0,06 | 0,15 |

| 2 | 15 | 20 | 30 | mm/z | 0,06 | 0,12 | 0,06 | 0,15 | 0,06 | 0,15 | |

| 3 | 20 | 30 | 40 | mm/z | 0,06 | 0,12 | 0,06 | 0,15 | 0,06 | 0,15 | |

| 4 | 20 | 30 | 40 | mm/z | 0,06 | 0,12 | 0,06 | 0,15 | 0,06 | 0,15 | |