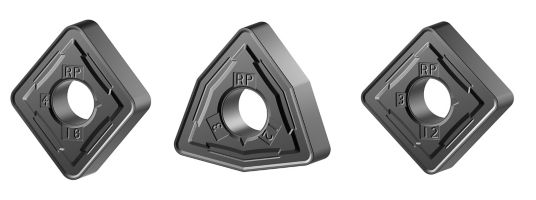

High-PIMS coating technology is characterized by:

- Smooth coating surface.

- Optimum layer adhesion, especially on sharp cutting edges.

- High depth-of-cut notching resistance.

- Long tool life, and high process reliability.

Applied on an extremely hard and wear-resistant ultrafine-grain carbide substrate, the KCS10B grade is ideal for medium machining and finishing operations.

The AlTiN PVD coating is ideal for iron-based alloys (S1), cobalt-based alloys (S2), and nickel-based alloys (S3).