Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Sign Out

Item(s) successfully added to cart

View Cart

View Cart

Take your shop to the next level. See Promotions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Holemaking

- /

- Solid Carbide Drills

- /

- KenDrill™ Deep HPR

- /

- KenDrill™ Deep HPR/SGL • 15 x D • Internal Coolant • Straight Shank • Metric

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

KenDrill™ Deep HPR/SGL • 15 x D • Internal Coolant • Straight Shank • Metric

Solid Carbide Deep Hole Drill for Cast Iron and Steels

Features and benefits

- Proven performance with our HPR drills geometry, featuring our heat and wear resistant KCK10A grade.

- High productivity with speed four times faster than conventional drills.

- Longer tool life in steel and iron compared to competitors.

- Bottom-line savings from increased metal removal rate.

Uses and application

Drilling

Drilling: Inclined Exit

Drilling: Stacked Plates

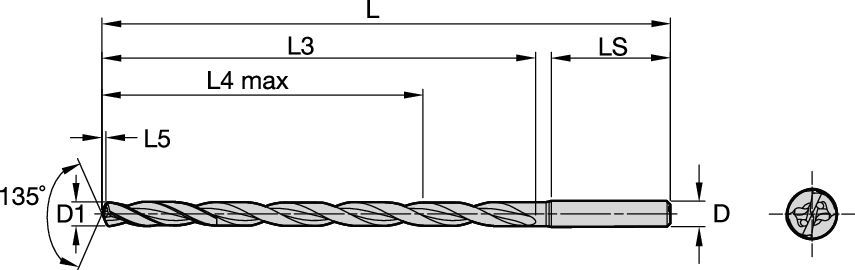

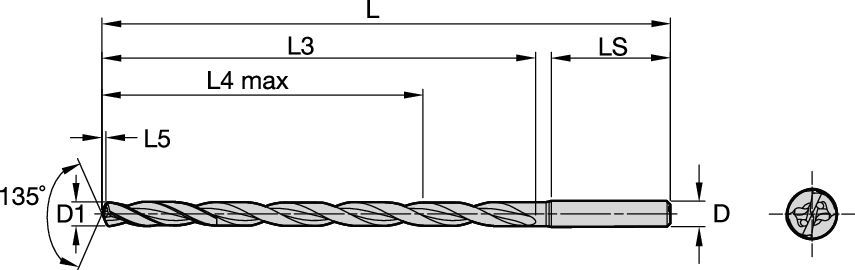

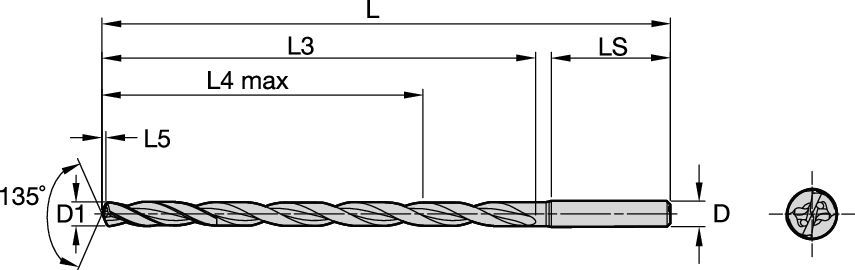

Tool Dimensions: 2flute/4margin/coolant

DIN number 6535

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling: Cross-Hole Drilling

| Application Data B27_HPR Series Grade KCK10A • Through Coolant • Inch | |||||||||||

| KCK10A | Feed rate (f) = IPR by diameter | ||||||||||

| Kesme hızı | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 9/16 | 5/8 | |||

| Malzeme grubu | Min. | Başlangıç değeri | Maks. | .125 | .188 | .250 | .313 | .375 | .500 | .551 | .625 |

| P | |||||||||||

| P0 | 330 | 330 | 410 | .005 | .006 | .006 | .008 | .008 | .010 | .012 | .013 |

| P1 | 300 | 330 | 360 | .006 | .006 | .007 | .009 | .010 | .012 | .014 | .016 |

| P2 | 300 | 330 | 360 | .006 | .006 | .007 | .009 | .010 | .012 | .014 | .016 |

| P3 | 260 | 310 | 360 | .006 | .006 | .007 | .009 | .010 | .012 | .014 | .016 |

| P4 | 260 | 300 | 360 | .006 | .006 | .007 | .009 | .010 | .012 | .014 | .016 |

| P5 | 200 | 260 | 300 | .001 | .002 | .002 | .002 | .003 | .004 | .005 | .006 |

| P6 | 200 | 230 | 260 | .001 | .002 | .002 | .002 | .003 | .004 | .005 | .006 |

| K | |||||||||||

| K1 | 260 | 330 | 390 | .006 | .007 | .008 | .009 | .011 | .013 | .015 | .018 |

| K2 | 260 | 300 | 330 | .006 | .006 | .007 | .009 | .010 | .012 | .014 | .016 |

| K3 | 200 | 300 | 390 | .006 | .006 | .007 | .009 | .010 | .012 | .014 | .016 |

| For MQL applications in P1-P4: Vc: 50% of through coolant data; f: 120% of through hole coolant data | |||||||||||

| Application Data B27_HPR Series Grade KCK10A • Through Coolant • Metric | |||||||||||

| Kesme hızı; | İlerleme oranı (f) = mm/r çap başına | ||||||||||

| Malzeme grubu | Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 |

| P | |||||||||||

| P0 | 100 | 100 | 125 | 0,13 | 0,14 | 0,15 | 0,19 | 0,21 | 0,26 | 0,30 | 0,34 |

| P1 | 90 | 100 | 110 | 0,15 | 0,16 | 0,18 | 0,22 | 0,25 | 0,30 | 0,35 | 0,40 |

| P2 | 90 | 100 | 110 | 0,15 | 0,16 | 0,18 | 0,22 | 0,25 | 0,30 | 0,35 | 0,40 |

| P3 | 80 | 95 | 110 | 0,15 | 0,16 | 0,18 | 0,22 | 0,25 | 0,30 | 0,35 | 0,40 |

| P4 | 80 | 90 | 110 | 0,15 | 0,16 | 0,18 | 0,22 | 0,25 | 0,30 | 0,35 | 0,40 |

| P5 | 60 | 80 | 90 | 0,03 | 0,04 | 0,05 | 0,05 | 0,08 | 0,11 | 0,12 | 0,14 |

| P6 | 60 | 70 | 80 | 0,03 | 0,04 | 0,05 | 0,05 | 0,08 | 0,11 | 0,12 | 0,14 |

| K | |||||||||||

| K1 | 80 | 100 | 120 | 0,15 | 0,17 | 0,19 | 0,24 | 0,27 | 0,32 | 0,38 | 0,45 |

| K2 | 80 | 90 | 100 | 0,15 | 0,16 | 0,18 | 0,22 | 0,25 | 0,30 | 0,35 | 0,40 |

| K3 | 60 | 90 | 120 | 0,15 | 0,16 | 0,18 | 0,22 | 0,25 | 0,30 | 0,35 | 0,40 |

| For MQL applications in P1-P4: Vc: 50% of through coolant data; f: 120% of through hole coolant data | |||||||||||