A Quick Tool Steel Overview

There’s neither the time nor space for a complete lesson on tool steels. Those interested can read more about it in this sample from ASM International’s Handbook, Volume 16: Machining Handbook. Otherwise, just know that so-called Mushet steel, which most consider the first true tool steel, left the furnace more than 150 years ago.

Because it could cut metal much more quickly than the hardened carbon steel tools of the day, they dubbed it high-speed steel. As you will see, that moniker has since become a bit misleading, as tungsten carbide cutting tools—though a bit less forgiving than HSS—are far faster and therefore much more productive.

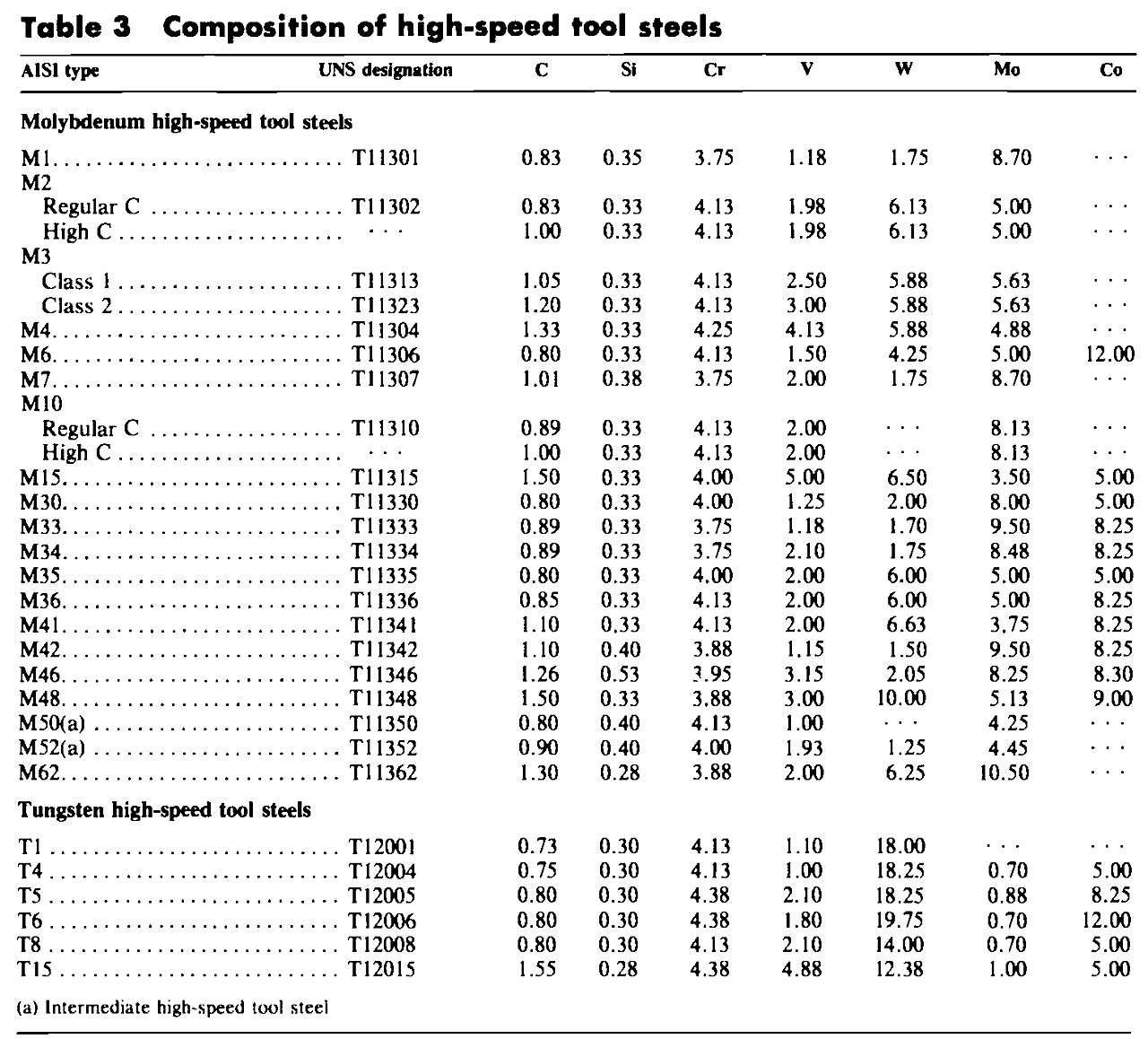

Regardless, metallurgists have continued adding various amounts and kinds of alloying elements to the tool steel crucible, among them tungsten, vanadium, chromium, and, most relevant to this discussion, cobalt. The result is six distinct groups of tool steel and many dozens of grades, a few of which we mentioned previously.