Product Similar To:

Chamfer Rings • For Use with Metric Kennametal Hydraulic Chucks • For Use with Inch or Metric Drills

SEFAS™ Bodies

Material Number1245743

ISO Catalog ID3.37538R016ANSI Catalog ID3.37538R016

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

Counter Sinking/ Stroke Chamfering

Drilling - Through Coolant

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 1245743 |

| ISO Catalog ID | 3.37538R016 |

| ANSI Catalog ID | 3.37538R016 |

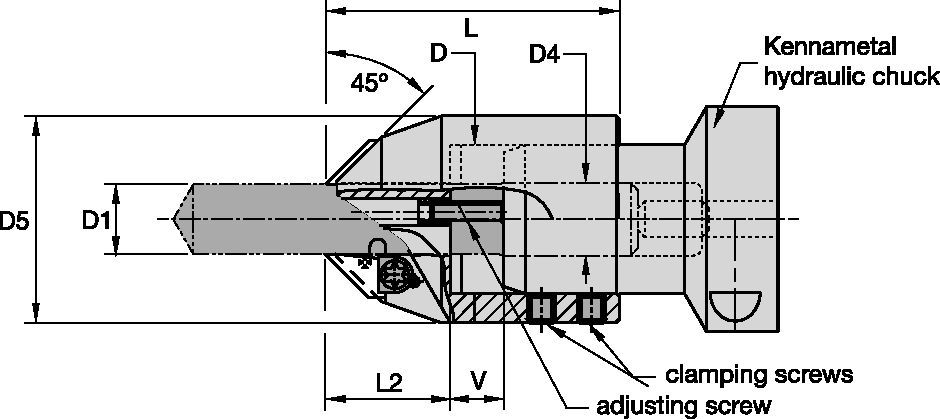

| [D1] Drill Diameter M | >14 mm |

| [D1] Drill Diameter M | >0.551 in |

| [D1MAX] Drill Diameter Maximum | 16 mm |

| [D1MAX] Drill Diameter Maximum | .63 in |

| [D] Adapter / Shank / Bore Diameter | 37.6 mm |

| [D] Adapter / Shank / Bore Diameter | 1.48 in |

| [D4] Mount Bore Diameter | 16 mm |

| [D4] Mount Bore Diameter | .63 in |

| [D5] Maximum Body Diameter | 54 mm |

| [D5] Maximum Body Diameter | 2.126 in |

| [L] Overall Length | 78 mm |

| [L] Overall Length | 3.071 in |

| [L2] Head Length | 32 mm |

| [L2] Head Length | 1.259 in |

| [V] Adjustment Range | 12 mm |

| [V] Adjustment Range | .472 in |

| Gage Insert | 3.42807. |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

Uses and application

Counter Sinking/ Stroke Chamfering

Drilling - Through Coolant

Features and benefits

- Drill body shipped with all screws, clamps, and wrenches.

- Order the inserts and drills separately.

- Use only with hydraulic chucks.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Dimension

| K210, K254, K284 | K211, K222, K255, K285, K411 | K212, K256 | unalloyed and low-alloy steel, unalloyed and alloy steel, and cast iron, high-alloy steel and stainless steel | ||||||

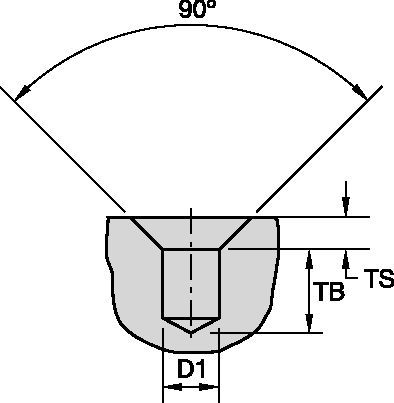

| drill diameter D1 | TBmin | TBmax | TBmin | TBmax | TBmin | TBmax | TS100 | TS80 | TSmax |

| .156 | not applicable (drill shank diameter | ||||||||

| .748 | 1.339 | 1.229 | 1.890 | 2.165 | 2.756 | .098 | .157 | .197 | |

| not applicable (drill shank diameter | |||||||||

| .906 | 1.732 | 1.614 | 2.441 | 3.110 | 3.937 | .157 | .236 | .315 | |

| not applicable (metric ring and hydraulic chuck are not interchangeable) | |||||||||

| 1.142 | 2.087 | 1.890 | 2.835 | 3.819 | 4.764 | .157 | .236 | .315 | |

|  |  |  | ||||||||

| B210, B221, B224, B254, B284, B291, B707, B966, B976 | B211, B222, B225, B285, B292, B411, B708, B977 | B212, B256, B709, B978 | B269 | unalloyed and low-alloy steel; unalloyed and alloy steel, and cast iron, high-alloy steel and stainless steel | |||||||

| drill diameter D1 | TBmin | TBmax | TBmin | TBmax | TBmin | TBmax | TBmin | TBmax | TS100 | TS80 | TSmax |

| 4,0 | 4 | 17 | 12 | 29 | 20 | 36 | 45 | 62 | 1,2 | 1,8 | 2,5 |

| 4 | 20 | 20 | 35 | 27 | 43 | 63 | 80 | 1,5 | 2,2 | 3,0 | |

| 11 | 24 | 23 | 40 | 32 | 49 | 71 | 88 | 2 | 3,0 | 4,0 | |

| 11 | 28 | 23 | 40 | 42 | 59 | 85 | 102 | 2,5 | 4,0 | 5,0 | |

| 13 | 29 | 27 | 43 | 46 | 62 | 109 | 125 | 2,5 | 4,0 | 5,0 | |

| 15 | 35 | 31 | 51 | 54 | 74 | 131 | 151 | 3,5 | 5,0 | 7,0 | |

| 21 | 36 | 38 | 53 | 69 | 84 | 160 | 175 | 4,0 | 6,0 | 8,0 | |

| 22 | 40 | 40 | 58 | 78 | 96 | 184 | 202 | 4,0 | 6,0 | 8,0 | |

| 31 | 45 | 51 | 65 | 93 | 107 | 213 | 227 | 4,0 | 6,0 | 8,0 | |

| 34 | 50 | 56 | 72 | 103 | 119 | 237 | 253 | 4,0 | 6,0 | 8,0 | |

I have read and accepted the Terms & Conditions of use