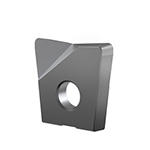

KDMT Ball Nose Platform • KDMS • KDMT

The KDMT indexable toroidal copy milling system is a proven solution for roughing and finishing operations. Engineered with a wide range of diameters and insert styles, this platform provides exceptional performance and productivity--especially during flat-bottom and back-draft finishing. The high feed insert style provides high removal rates and precision accuracy. The KDMT copy milling system can be used on a variety of workpiece materials ranging from hardened steel to aluminum. The wide diameter range enables the system to be applied across several types of machining conditions. Toolholders are available with screw-on and cylindrical shanks. KDMS precision inserts are also available.