Product Similar To:

DFS KM40TS Shank • KM50TS Shank • 3 x D • Right Hand • Metric

Drill Fix™ DFSP™ Bodies

Material Number5129110

ISO Catalog IDKM50TSDFS260R3MANSI Catalog IDKM50TSDFS260R3M

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: X-Offset

Drilling: Convex

Shank - KM-TS ISO 26622

Through Coolant: Radial: Indexable Drilling

Drilling: Blind

Chain Drilling

Drilling: Cross-Hole Drilling

Drilling: Half-Cylindrical Drilling

Drilling: Corner Drilling 45°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

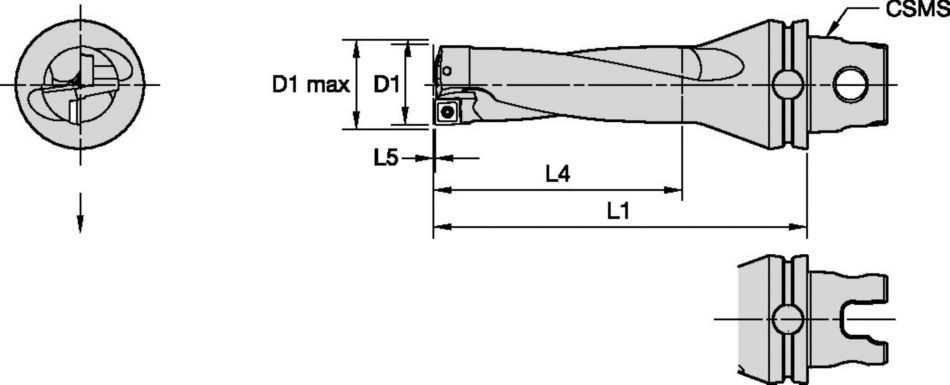

| Material Number | 5129110 |

| ISO Catalog ID | KM50TSDFS260R3M |

| ANSI Catalog ID | KM50TSDFS260R3M |

| [CSMS] System Size Machine Side | KM50TS |

| [D1] Drill Diameter M | 26 mm |

| [D1] Drill Diameter M | 1.023 in |

| [D1MAX] Drill Diameter Maximum | 28 mm |

| [D1MAX] Drill Diameter Maximum | 1.102 in |

| [L1] Insert Gage Length | 118 mm |

| [L1] Insert Gage Length | 4.645 in |

| [L4] Maximum Drilling Depth | 78 mm |

| [L4] Maximum Drilling Depth | 3.07 in |

| [L5] Drill Point Length | 0.64 mm |

| [L5] Drill Point Length | .0252 in |

| Gage Insert | SPPX09T3. |

| Gage Insert 2 | DFT05T3. |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

Uses and application

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: X-Offset

Drilling: Convex

Shank - KM-TS ISO 26622

Through Coolant: Radial: Indexable Drilling

Drilling: Blind

Chain Drilling

Drilling: Cross-Hole Drilling

Drilling: Half-Cylindrical Drilling

Drilling: Corner Drilling 45°

Features and benefits

- DFSP combines the economical squared outboard insert with the superior centering capabilities of the trigon inboard insert.

- Benefit from the KM-TS™ coupling as it is the most precise and stable tooling system allowing fully automated tool changing.

- Drill shipped with insert screws and Torx wrench.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Warning

Warnings • Drill Fix DFR

| UYARI Delme işlemleri sırasında, matkap iş parçasını delip geçtiğinde işlenmemiş bir metal parçası veya delik sonunda pul oluşur. Matkap sabitken ve iş parçası dönerken bu parçalar merkezkaç kuvvetiyle takım tutucudan fırlayabilir. Çevredeki kişileri korumak üzere yeterli önlemlerin alınması gereklidir. |

I have read and accepted the Terms & Conditions of use