Product Similar To:

T660 • Machine Screw and Fractional • Form D Plug Chamfer

Beyond™ Left-Hand Spiral-Flute, Right-Hand Cut HSS-E-PM Taps • Through Holes

Material Number5565559

ISO Catalog IDT660NF03125-24RH4-AANSI Catalog IDT660NF03125-24RH4-A

- S High-Temp Alloys

Tapping: Through Hole

Chamfer Form D (3.5–5)

HSS-E-PM

Flood Coolant: Tapping

Manufacturer’s Specs: UNF

Manufacturer’s Specs: UNC

Manufacturer’s Specs: ANSI

Tapping Helix Angle: L15°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

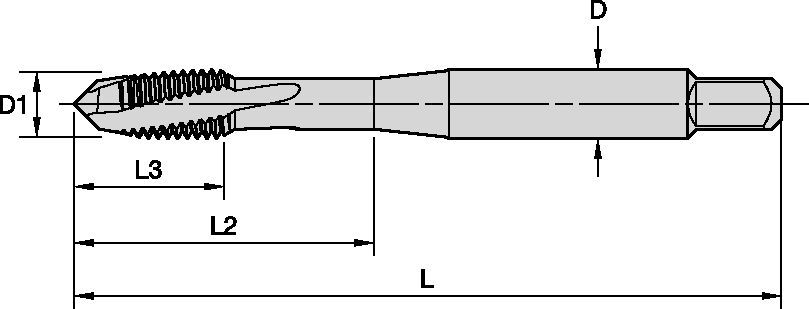

| Material Number | 5565559 |

| ISO Catalog ID | T660NF03125-24RH4-A |

| ANSI Catalog ID | T660NF03125-24RH4-A |

| Grade | KSS20 |

| [D1-TDZ] Thread Diameter Size | 5/16 - 24 |

| [L] Overall Length | 69 mm |

| [L] Overall Length | 2.72 in |

| [L3] Thread Length | 12.4 mm |

| [L3] Thread Length | .49 in |

| [L2] Useable Length | 28.8 mm |

| [L2] Useable Length | 1.13 in |

| [D] Adapter / Shank / Bore Diameter | 8.077 mm |

| [D] Adapter / Shank / Bore Diameter | .318 in |

| [Z] Number of Flutes | 3 |

| Tap Pitch Diameter Limit | H4 |

Workpiece Materials

- High-Temp Alloys

Uses and application

Tapping: Through Hole

Chamfer Form D (3.5–5)

HSS-E-PM

Flood Coolant: Tapping

Manufacturer’s Specs: UNF

Manufacturer’s Specs: UNC

Manufacturer’s Specs: ANSI

Tapping Helix Angle: L15°

Features and benefits

- KSS20 nitride for titanium and titanium alloys.

- KSSM24 TiN + CrC/C for titanium and titanium alloys.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Tolerance

Tolerances

| shank tolerance | |

| D | tolerance h6 + / - |

| .250–.375 | +0, -.0004 |

| .438–.625 | +0, -.0004 |

Speeds & Feeds

| Material |  |  | |||||||||

| Through Holes | Blind Holes | ||||||||||

| Range | Range | ||||||||||

| Tap Style | Grade | Min | Starting Value | Max | Tap Style | Grade | Min | Starting Value | Max | ||

| S | 4 | T660 | KSSM24 | 3 | 4 | 6 | T662 | KSSM24 | 2 | 3 | 4 |

| T660 | KSS20 | 1.6 | 2.4 | 3.6 | T662 | KSS20 | 1.3 | 1.7 | 2.2 | ||

|  | ||||||||||

| Through Holes | Blind Holes | ||||||||||

| Range | Range | ||||||||||

| Material | Tap Style | Grade | Min | Starting Value | Max | Tap Style | Grade | Min | Starting Value | Max | |

| S | 4 | T660 | KSSM24 | 9 | 13 | 20 | T662 | KSSM24 | 7 | 9 | 12 |

| 4 | T660 | KSS20 | 5 | 8 | 12 | T662 | KSS20 | 4 | 6 | 7 | |

Application Data

| Material |  |  | |||||||||

| Through Holes | Blind Holes | ||||||||||

| Range | Range | ||||||||||

| Tap Style | Grade | Min | Starting Value | Max | Tap Style | Grade | Min | Starting Value | Max | ||

| S | 4 | T660 | KSSM24 | 3 | 4 | 6 | T662 | KSSM24 | 2 | 3 | 4 |

| T660 | KSS20 | 1.6 | 2.4 | 3.6 | T662 | KSS20 | 1.3 | 1.7 | 2.2 | ||

|  | ||||||||||

| Through Holes | Blind Holes | ||||||||||

| Range | Range | ||||||||||

| Material | Tap Style | Grade | Min | Starting Value | Max | Tap Style | Grade | Min | Starting Value | Max | |

| S | 4 | T660 | KSSM24 | 9 | 13 | 20 | T662 | KSSM24 | 7 | 9 | 12 |

| 4 | T660 | KSS20 | 5 | 8 | 12 | T662 | KSS20 | 4 | 6 | 7 | |

I have read and accepted the Terms & Conditions of use