TMS

Filters

Filters

View filters in

MetricInch

Workpiece Material

Workpiece Material

- P Steel (81)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(81)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(81)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(81)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(81)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(81)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(81)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(81)

- M Stainless Steel (81)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(81)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(81)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(81)

- K Cast Iron (81)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(81)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(81)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(81)

- S High-Temp Alloys (34)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(34)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(34)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(34)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(34)

- H Hardened Materials (74)

- H1Hardened Materials 44-48 HRC(74)

Applications

Applications

ID Thread Turning (39)

OD Thread Turning (22)

Thread Milling (34)

Threading (34)

Cutting Diameter

Cutting Diameter

- 8.992 mm(2)

- 9.0 mm(2)

- 9.9 mm(1)

- 10.135 mm(1)

- 11.43 mm(2)

- 11.5 mm(2)

- 15.494 mm(1)

- 15.5 mm(2)

- 17.0 mm(1)

- 17.018 mm(2)

- 19.0 mm(1)

- 19.05 mm(1)

- 20.0 mm(1)

- 20.066 mm(1)

- 22.0 mm(1)

- 22.098 mm(1)

- 25.0 mm(1)

- 26.0 mm(1)

- 26.01 mm(1)

- 29.972 mm(3)

- 30.0 mm(2)

- 37.0 mm(1)

- 37.084 mm(1)

- 42.0 mm(1)

- 42.012 mm(1)

to

Cutting Length

Cutting Length

- 10.4 mm(2)

- 10.41 mm(2)

- 10.92 mm(3)

- 10.922 mm(1)

- 11.0 mm(3)

- 16.0 mm(11)

- 16.002 mm(2)

- 26.92 mm(4)

- 26.924 mm(1)

- 27.0 mm(5)

to

Type of Thread

Type of Thread

- BSW (37)

- M (48)

- NPS (15)

- NPT (23)

- NPTF (23)

- UN (42)

Reach

Reach

- 11.94 mm(1)

- 11.99 mm(1)

- 12.0 mm(2)

- 15.49 mm(1)

- 15.5 mm(1)

- 16.99 mm(1)

- 17.0 mm(1)

- 20.0 mm(1)

- 20.07 mm(1)

- 20.5 mm(1)

- 22.0 mm(2)

- 22.1 mm(2)

- 23.0 mm(1)

- 23.11 mm(1)

- 25.0 mm(1)

- 25.4 mm(1)

- 34.04 mm(1)

- 40.0 mm(1)

- 42.67 mm(1)

- 42.93 mm(1)

- 43.0 mm(2)

- 44.96 mm(1)

- 45.0 mm(1)

- 51.56 mm(2)

- 52.0 mm(1)

- 58.0 mm(1)

- 89.66 mm(1)

- 92.0 mm(1)

- 101.6 mm(1)

to

Tool Cutting Edge Angle

Tool Cutting Edge Angle

- 90.0 (17)

to

Connection Style

Connection Style

- Weldon (34)

Number of Flutes

Number of Flutes

- 1 (29)

- 2 (5)

Cutting Edges Per Insert

Cutting Edges Per Insert

- 1.0 (24)

- 2.0 (77)

to

Internal Coolant Capability

Internal Coolant Capability

Over All Length [L]

Over All Length [L]

- 69.0 mm(1)

- 69.088 mm(1)

- 69.85 mm(1)

- 70.0 mm(1)

- 77.0 mm(1)

- 79.248 mm(1)

- 80.0 mm(1)

- 83.82 mm(1)

- 84.0 mm(1)

- 85.0 mm(2)

- 85.852 mm(1)

- 86.868 mm(1)

- 88.9 mm(1)

- 90.0 mm(1)

- 90.424 mm(2)

- 91.0 mm(1)

- 95.0 mm(1)

- 95.25 mm(1)

- 98.0 mm(1)

- 100.0 mm(1)

- 102.108 mm(1)

- 110.0 mm(1)

- 111.252 mm(2)

- 118.11 mm(1)

- 120.0 mm(2)

- 125.0 mm(1)

- 127.0 mm(1)

- 149.352 mm(1)

- 150.0 mm(1)

- 160.782 mm(1)

to

Application

Grade Of Cutting Tool

Grade Of Cutting Tool

- KC610M (34)

- KC620M (30)

- KC635M (74)

Hand Of Tool

Hand Of Tool

- R (34)

Wiper Insert

Wiper Insert

- N (47)

Countersunk Angle

Countersunk Angle

- 27.5 (7)

- 30.0 (40)

to

Front-End

Cutting Width

Cutting Width

- 8.382 mm(1)

- 8.636 mm(1)

- 8.89 mm(3)

- 9.144 mm(1)

- 9.398 mm(1)

- 9.652 mm(3)

- 9.906 mm(5)

- 10.16 mm(1)

- 10.414 mm(1)

- 13.208 mm(3)

- 13.97 mm(5)

- 14.224 mm(3)

- 14.478 mm(7)

- 14.732 mm(4)

- 14.986 mm(4)

- 18.0 mm(1)

- 23.114 mm(1)

- 23.876 mm(1)

- 24.5 mm(1)

to

Thread TPI

Thread TPI

- 11.0 (26)

- 11.5 (16)

- 12.0 (15)

- 14.0 (28)

- 16.0 (23)

- 18.0 (16)

- 19.0 (8)

- 20.0 (27)

- 24.0 (23)

- 27.0 (14)

- 32.0 (14)

to

Thread Pitch

Thread Pitch

- 0.75 mm(18)

- 1.0 mm(37)

- 1.25 mm(25)

- 1.5 mm(38)

- 1.75 mm(18)

- 2.0 mm(32)

- 2.5 mm(13)

- 3.0 mm(11)

- 3.5 mm(11)

- 4.0 mm(10)

- 4.5 mm(10)

to

Neck Diameter

Neck Diameter

- 6.8 mm(2)

- 7.366 mm(1)

- 7.4 mm(1)

- 8.9 mm(2)

- 12.2 mm(1)

- 12.446 mm(1)

- 12.5 mm(1)

- 13.6 mm(1)

- 14.986 mm(1)

- 15.0 mm(1)

- 16.6 mm(1)

- 18.6 mm(1)

- 19.0 mm(1)

- 22.5 mm(1)

- 23.876 mm(1)

- 24.0 mm(2)

- 31.0 mm(1)

- 36.0 mm(1)

to

Insert Geometry

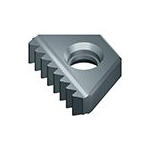

Shape

Shape

- TM-TRIANGLE THREAD MILL 60 (47)

Insert IC Size

Insert IC Size

- 6.0 mm(6)

- 6.35 mm(11)

- 9.525 mm(26)

- 12.7 mm(1)

- 15.875 mm(3)

to

Cutting Tool Material

Cutting Tool Material

- H W (47)

Back-End

Connection Type

Connection Type

- CYLINDRICAL (34)

Back-End Diameter

Back-End Diameter

- 12.0 mm(2)

- 12.7 mm(2)

- 15.875 mm(2)

- 16.0 mm(3)

- 19.05 mm(6)

- 20.0 mm(5)

- 25.0 mm(5)

- 25.4 mm(5)

- 31.75 mm(2)

- 32.0 mm(2)

to

No filters matching ""