What is a blast nozzle?

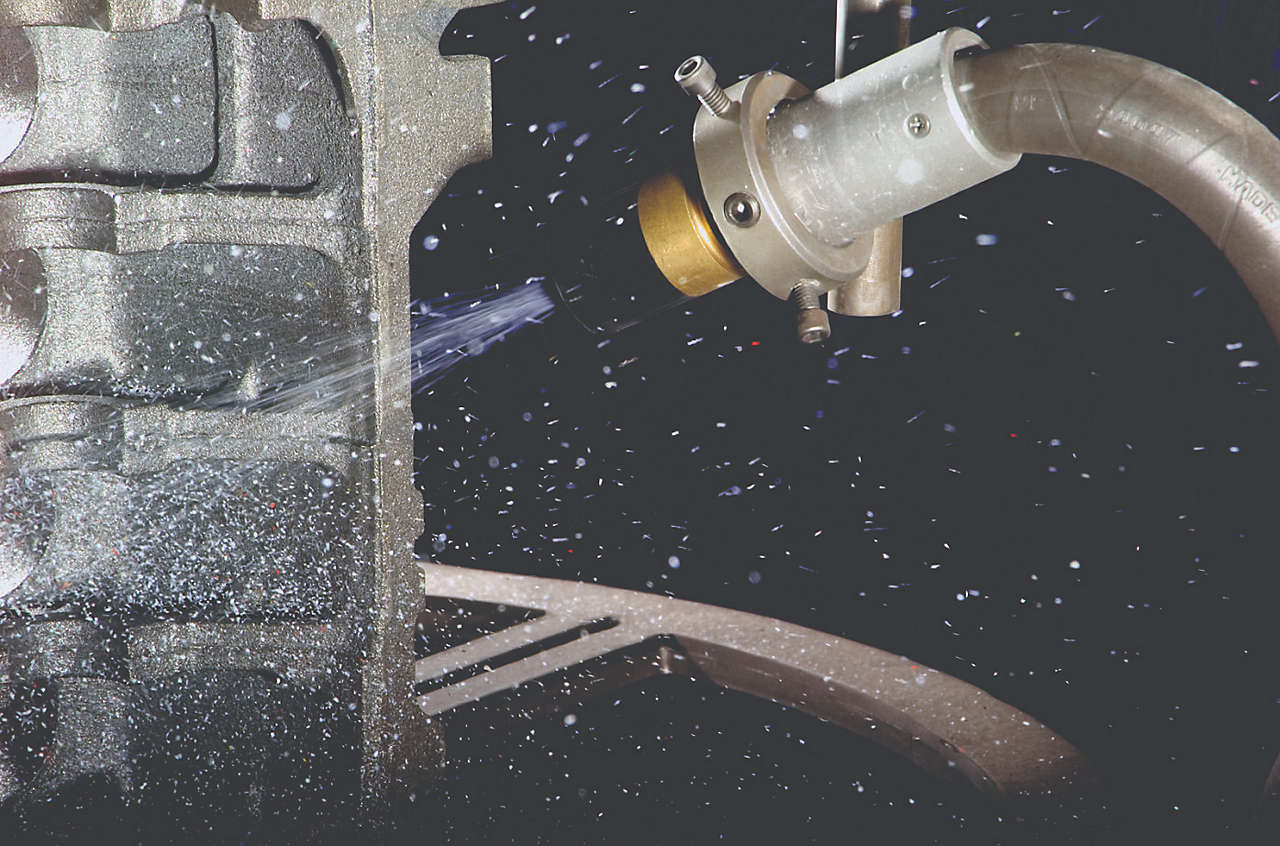

A blast nozzle is a device used to propel abrasive particles at a surface at high velocity to smooth a rough surface, roughen a smooth surface, shape a surface, or remove surface contaminants. Blast nozzles are used in a variety of applications across many industries.

A grouping of long Venturi blast nozzles.

What materials are blast nozzles manufactured from?

Blast nozzles are typically made of steel, alumina, tungsten carbide, silicon nitride, silicon carbide, boron carbide, and ROCTEC™. The nozzle material is important because it affects the durability and wear resistance of the nozzle. Tungsten carbide nozzles are the most common type and are a good choice for general-purpose blasting. Alumina nozzles are lower-priced than carbide nozzles but they are not as durable.

The type of abrasive you use will also affect impact the nozzle service lifesize you need. Finer, harder, and sharper abrasives , such as sand, require smaller nozzles than coarser abrasives result in shorter nozzle service life, such as steel shot.

Straight-Bore Nozzles

What Personal Protective Equipment (PPE) must be used while abrasive blasting?

- Abrasive blasting respirator: This type of respirator covers the head, neck, and shoulders to protect the wearer from rebounding abrasive and dust. It must be NIOSH-certified for abrasive blasting.

- Blast suit: A blast suit is a full-body suit that protects the wearer from abrasive material, dust, and other hazards. It should be made of a durable material, such as nylon or Kevlar.

- Gloves: Gloves should be made of a durable material that can protect the wearer from abrasive material, dust, and chemicals.

- Boots: Boots should be made of a durable material that can protect the wearer from abrasive material, dust, and chemicals. They should also be slip-resistant.

- Hard hat: A hard hat protects the wearer from head injuries.

- Eye protection: Eye protection, such as safety glasses or a goggles, protects the wearer from flying debris and dust.

In addition to the essential PPE listed above, workers may also need to wear other PPE depending on the specific abrasive blasting operation being performed. For example, workers who are abrasive blasting with materials that contain lead or other hazardous materials may need to wear additional respiratory protection and clothing.

It is important to note that all PPE must be properly fitted and maintained in order to be effective. Workers should be trained on how to properly use and maintain their PPE.

Important considerations when choosing a blast nozzle.

Blast nozzles are an essential part of any abrasive blasting system. By choosing the right type of nozzle for your application, you can ensure that you get the best results from your blasting process.

Consider the nozzle material. Blast nozzles are typically made of steel, aluminum, or carbide. Steel nozzles are the most common type and are a good choice for general-purpose blasting. Aluminum nozzles are more lightweight and less expensive than steel nozzles, but they are not as durable. Carbide nozzles are the most durable type of nozzle, but they are also the most expensive.

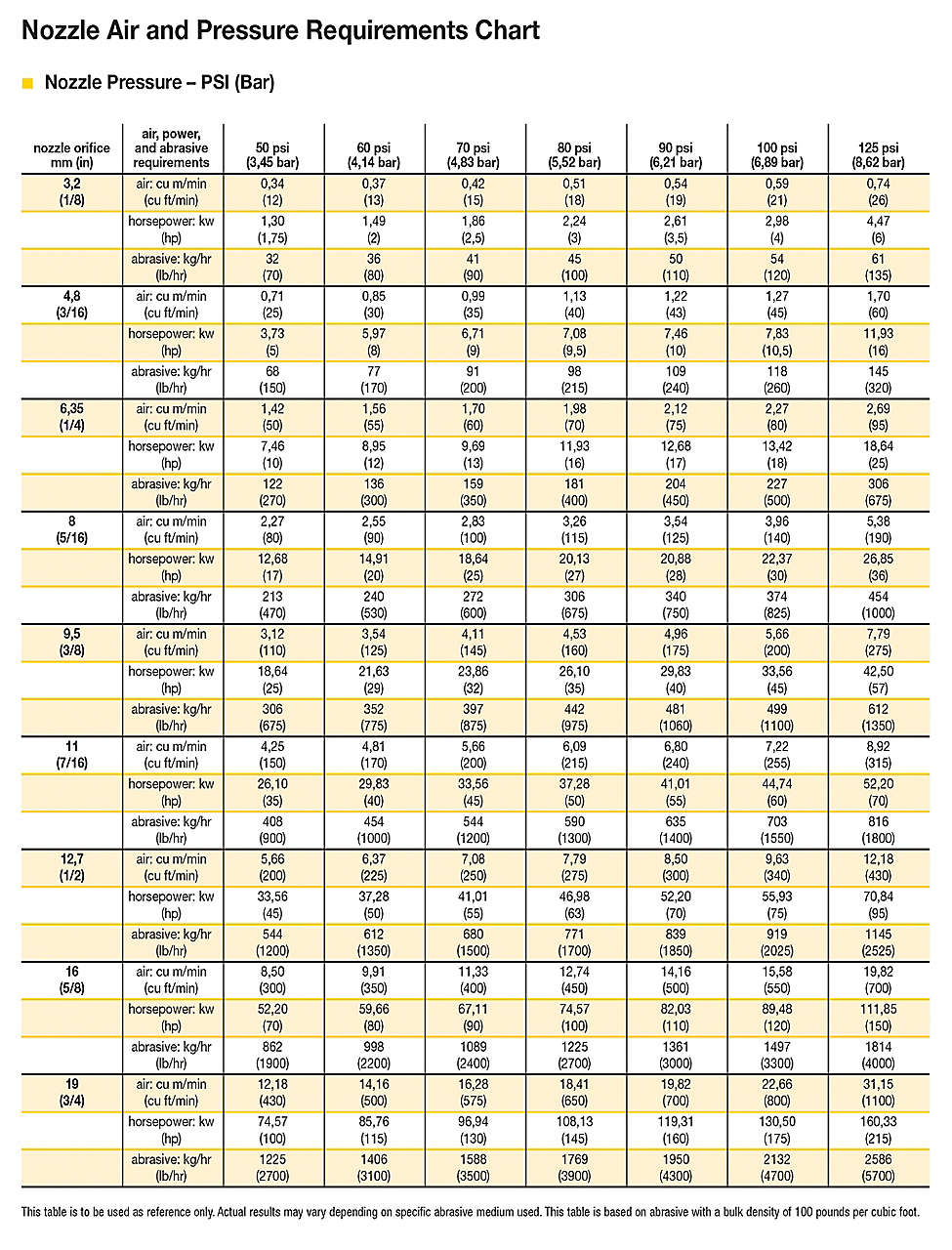

Select the nozzle size. The nozzle size is determined by the diameter of the nozzle opening. The smaller the nozzle opening, the higher the pressure and velocity of the abrasive blast. Nozzles with smaller openings are typically used for surface preparation, while nozzles with larger openings are used for cleaning and descaling.

Choose the right abrasive. The type of abrasive you use will also affect the nozzle size you need. Finer abrasives, such as sand, require smaller nozzles than coarser abrasives, such as steel shot.

Consider the blast pressure. The blast pressure is the amount of force that is used to propel the abrasive through the nozzle. The higher the blast pressure, the more aggressive the blasting process will be. However, too much blast pressure can damage the surface being blasted.

Take safety precautions. When using a blast nozzle, it is important to wear safety glasses, a dust mask, and hearing protection. It is also important to keep the nozzle clean to prevent clogging.

Here are some additional tips for choosing the right blast nozzle for abrasive blasting:

If you are not sure what type of nozzle to use, contact us, and our nozzle experts can diagnose and solve your toughest blasting challenges.

Make sure the nozzle is compatible with your blasting equipment.

Inspect the nozzle regularly for wear and tear. Replace the nozzle as needed.

Nozzle Air and Pressure Requirements Chart

Related Articles

- Revolutionizing Road Construction: Embracing Renewable MaterialsBy incorporating an ESG strategy in road rehabilitation we can overcome harmful environmental challenges and build a greener future. Learn more from Kennametal.By incorporating an ESG strategy in road rehabilitation we can overcome harmful environmental challenges and build a greener future. Learn more from Kennametal.

- Proven Solutions: Kennametal Grader Teeth Improve Bite with Next-Level ProtectionKennametal’s latest grader tooth design features an innovative retainer and washer combination for next level block face and bore protection. But don’t take our word for it, read all about this in our proven solution.Kennametal’s latest grader tooth design features an innovative retainer and washer combination for next level block face and bore protection. But don’t take our word for it, read all about this in our proven solution.

- KenCast™ Mining Solutions: Breaking Through Abrasion Resistance in Crushing OperationsKennametal's KenCast™ sets new standards for abrasion resistance in ore production operations. Don’t just take our word for it, check out the results from one of our tests.Kennametal's KenCast™ sets new standards for abrasion resistance in ore production operations. Don’t just take our word for it, check out the results from one of our tests.

- Navigating the Regulatory Landscape: Compliance and Challenges for Underground Mining in the USAExplores key regulations for underground mining, some of the challenges and best practices for managing the costs and regulatory requirements.Explores key regulations for underground mining, some of the challenges and best practices for managing the costs and regulatory requirements.