Energy is everywhere. Around us in the wind, below us in oil, gas, and coal supplies. Harvesting this energy often means you're working in high-wear conditions. That means a high risk of equipment damage.

Kennametal is there, too, with a solution for nearly every area of the energy industry. Whether it’s oil and gas drilling and production, petrochemical processing, plastics manufacturing, coal energy and oil sands processing, or renewable energy, we have a myriad of custom wear solutions.

Wear is everywhere. And so are we.

Our Energy Solutions:

- Coal EnergyThe coal energy industry has demanding environments. Coal-fired power produces extremely abrasive, corrosive, and erosive environments. Fly ash and other particulates cause severe damage to boiler tubes, fan blades, coal burner components, pulverizers, and ash conveyance systems. Left unprotected, these components are less productive, more costly to operate, and prone to frequent failure.The coal energy industry has demanding environments. Coal-fired power produces extremely abrasive, corrosive, and erosive environments. Fly ash and other particulates cause severe damage to boiler tubes, fan blades, coal burner components, pulverizers, and ash conveyance systems. Left unprotected, these components are less productive, more costly to operate, and prone to frequent failure.

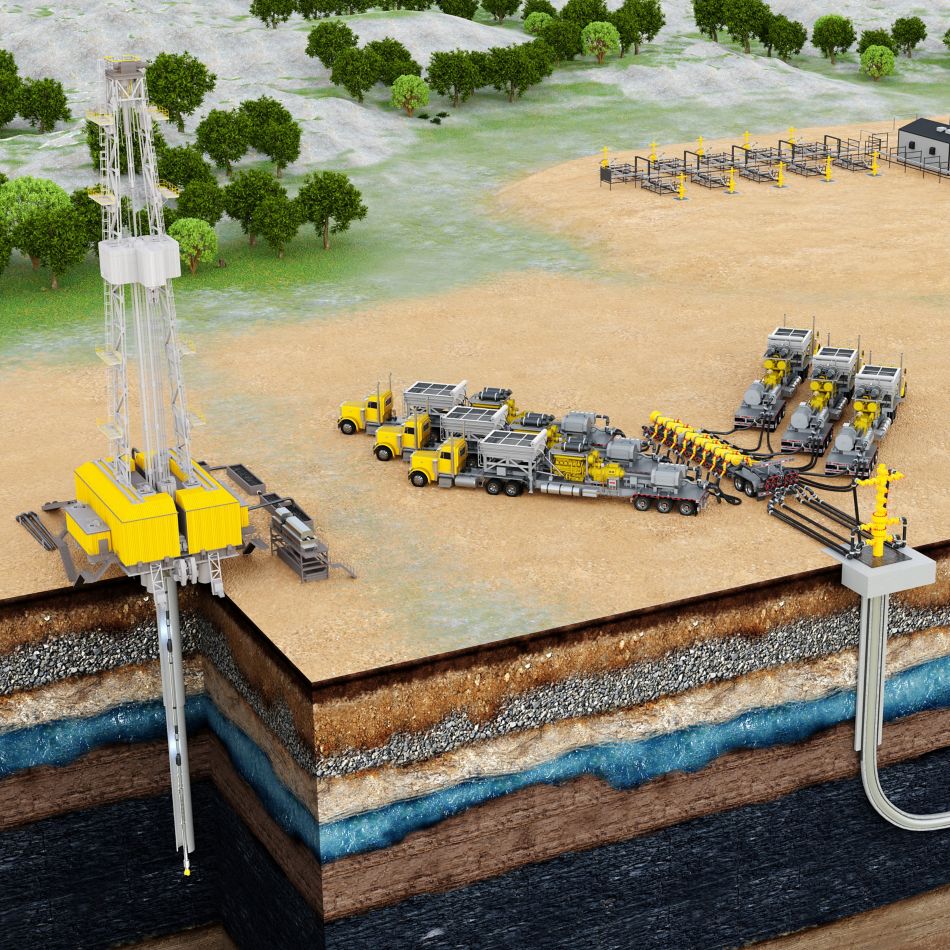

- Oil & Gas ProductionComponents are often the first barriers between demanding environments and the production system. Regardless of size, components are critical to production, especially when product life is measured in years.Components are often the first barriers between demanding environments and the production system. Regardless of size, components are critical to production, especially when product life is measured in years.

- Oil SandsBrutal. It’s an accurate description of the damaging wear encountered in petroleum extraction in the oil sands industry. Combine clay, sand, water, and bitumen, along with how this material is liquefied and transported, and you have the perfect storm of wear challenges.Brutal. It’s an accurate description of the damaging wear encountered in petroleum extraction in the oil sands industry. Combine clay, sand, water, and bitumen, along with how this material is liquefied and transported, and you have the perfect storm of wear challenges.

- PetrochemicalErosion, corrosion, and abrasion are your constant companions during petrochemical production. They usually determine the performance and life of a component. Kennametal’s cladding protects your equipment at multiple steps in the process, and in multiple ways.Erosion, corrosion, and abrasion are your constant companions during petrochemical production. They usually determine the performance and life of a component. Kennametal’s cladding protects your equipment at multiple steps in the process, and in multiple ways.

- PlasticsPlastics production is high and tight: High-volume production and tight quality requirements. Wear affects many parts of the production process, and takes many forms. Erosion, corrosion, and abrasion can damage extruder barrels, liners, dies, pipes, elbows, valves, and chutes, and halt production.Plastics production is high and tight: High-volume production and tight quality requirements. Wear affects many parts of the production process, and takes many forms. Erosion, corrosion, and abrasion can damage extruder barrels, liners, dies, pipes, elbows, valves, and chutes, and halt production.

- Processing IndustriesKennametal offers start-to-finish wear solutions. We start with a full assessment of your operation and wear challenges. Then we design solutions for those wear areas. Next, we create cladding fabric for wear-affected components and give installation support. We finish strong with ongoing support and wear monitoring.Kennametal offers start-to-finish wear solutions. We start with a full assessment of your operation and wear challenges. Then we design solutions for those wear areas. Next, we create cladding fabric for wear-affected components and give installation support. We finish strong with ongoing support and wear monitoring.