Product Similar To:

Inserts for KDMB • KDMB-GN • Inch

Indexable Inserts

Material Number6784086

ISO Catalog IDKDMB1000M0ERGNANSI Catalog IDKDMB1000M0ERGN

- P Steel

- M Stainless Steel

- K Cast Iron

- H Hardened Materials

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6784086 |

| ISO Catalog ID | KDMB1000M0ERGN |

| ANSI Catalog ID | KDMB1000M0ERGN |

| Grade | KCPK10 |

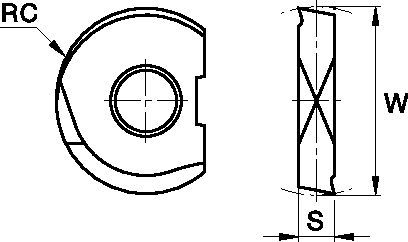

| [W] Cutting Width | 25.4 mm |

| [W] Cutting Width | 1 in |

| [S] Insert Thickness | 4 mm |

| [S] Insert Thickness | .1575 in |

| [RC] Corner Radius Center | 12.7 mm |

| [RC] Corner Radius Center | .5 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Hardened Materials

Grades

KCPK10

Composition: Advanced CVD TiCN-Al2O3 coating combined with a cobalt-enriched carbide substrate.

Application: The KCPK10 grade offers a balanced combination of deformation resistance and edge toughness leading to outstanding abrasion and crater wear resistance for high-speed machining of steel and cast iron. Use for very high cutting speeds with low to medium feed rates.

Features and benefits

- High-precision insert.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

KDMB Ball Nose Platform • .250"

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC515M | .E..GP | KC515M | – | – |

KDMB Ball Nose Platform • .312"

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | – | – | – | – |

| K3 | .E..GP | KC515M | – | – | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

KDMB Ball Nose Platform • .375"

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

KDMB Ball Nose Platform • .500"

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

KDMB Ball Nose Platform • .625"

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

KDMB Ball Nose Platform • .750"

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

KDMB Ball Nose Platform • 1.00"

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

KDMB Ball Nose Platform • 1.25"

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | – | – | – | – |

| K3 | .E..GP | KC515M | – | – | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | ||

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

Feeds

KDMB Ball Nose • .250"

| Working Diameter (Dw) at Axial Depth of Cut (ap) | ||||

| D1 max | 0.125 | 0.050 | 0.025 | 0.013 |

| 0.250 | 0.250 | 0.200 | 0.150 | 0.109 |

At .125 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .050 Axial Depth of Cut (ap)

| Light | General | Heavy |

At .025 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

At .013 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .006 | .008 | .015 | .004 | .006 | .011 | .004 | .005 | .010 | .004 | .005 | .009 | .004 | .005 | .009 | .E..LD |

| .E..GP | .006 | .008 | .015 | .004 | .006 | .011 | .004 | .005 | .010 | .004 | .005 | .009 | .004 | .005 | .009 | .E..GP |

KDMB Ball Nose • .312"

| Working Diameter (Dw) at Axial Depth of Cut (ap) | ||||

| D1 max | 0.156 | 0.047 | 0.031 | 0.016 |

| 0.313 | 0.313 | 0.223 | 0.188 | 0.136 |

At .156 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .047 Axial Depth of Cut (ap)

| Light | General | Heavy |

At .031 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

At .016 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

KDMB Ball Nose • .375"

| Working Diameter (Dw) at Axial Depth of Cut (ap) | ||||

| D1 max | 0.188 | 0.056 | 0.038 | 0.019 |

| 0.375 | 0.375 | 0.268 | 0.225 | 0.163 |

At .188 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .056 Axial Depth of Cut (ap)

| Light | General | Heavy |

At .038 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

At .019 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

KDMB Ball Nose • .500"

| Working Diameter (Dw) at Axial Depth of Cut (ap) | ||||

| D1 max | 0.250 | 0.075 | 0.050 | 0.025 |

| 0.500 | 0.500 | 0.357 | 0.300 | 0.218 |

At .250 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .075 Axial Depth of Cut (ap)

| Light | General | Heavy |

At .050 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

At .025 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • .625"

| Working Diameter (Dw) at Axial Depth of Cut (ap) | ||||

| D1 max | 0.313 | 0.094 | 0.063 | 0.031 |

| 0.625 | 0.625 | 0.446 | 0.375 | 0.272 |

At .313 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .094 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

At .063 Axial Depth of Cut (ap)

| Light | General | Heavy |

At .031 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • .750"

| Working Diameter (Dw) at Axial Depth of Cut (ap) | ||||

| D1 max | 0.375 | 0.113 | 0.075 | 0.038 |

| 0.750 | 0.750 | 0.536 | 0.450 | 0.327 |

At .375 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .113 Axial Depth of Cut (ap)

| Light | General | Heavy |

At .075 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

At .038 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • 1.00"

| Working Diameter (Dw) at Axial Depth of Cut (ap) | ||||

| D1 max | 0.500 | 0.150 | 0.100 | 0.050 |

| 1.000 | 1.000 | 0.714 | 0.600 | 0.436 |

At .500 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .150 Axial Depth of Cut (ap)

| Light | General | Heavy |

At .100 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

At .050 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • 1.25"

| Working Diameter (Dw) at Axial Depth of Cut (ap) | ||||

| D1 max | 0.625 | 0.188 | 0.125 | 0.063 |

| 1.250 | 1.250 | 0.893 | 0.750 | 0.545 |

At .625 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .188 Axial Depth of Cut (ap)

| Light | General | Heavy |

At .125 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

At .063 Axial Depth of Cut (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

Speeds

Recommended Starting Speeds [SFM]

| Material Group | K115M | KC505M | KC515M | KC530M | |||||||||

| P | 1 | – | – | – | – | – | – | 1080 | 960 | 840 | 900 | 780 | 660 |

| 2 | – | – | – | – | – | – | 1020 | 900 | 780 | 780 | 660 | 540 | |

| 3 | – | – | – | – | – | – | 900 | 780 | 660 | 660 | 600 | 540 | |

| 4 | – | – | – | 1180 | 860 | 710 | 780 | 660 | 540 | 600 | 540 | 480 | |

| 5 | – | – | – | 1180 | 860 | 710 | 660 | 540 | 420 | 540 | 480 | 420 | |

| 6 | – | – | – | 1140 | 780 | 620 | 540 | 420 | 360 | 420 | 360 | 300 | |

| M | 1 | – | – | – | – | – | – | 1080 | 900 | 780 | 900 | 720 | 600 |

| 2 | – | – | – | – | – | – | 900 | 720 | 540 | 600 | 480 | 420 | |

| 3 | – | – | – | – | – | – | 720 | 600 | 480 | 480 | 420 | 360 | |

| K | 1 | 720 | 600 | 480 | – | – | – | 1440 | 1080 | 720 | – | – | – |

| 2 | 600 | 480 | 360 | – | – | – | 1080 | 840 | 600 | – | – | – | |

| 3 | 360 | 300 | 240 | – | – | – | 480 | 360 | 240 | – | – | – | |

| N | 1–2 | 1440 | 1080 | 720 | – | – | – | – | – | – | – | – | – |

| 3 | 960 | 720 | 600 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | 300 | 230 | 160 | – | – | – | – | – | – | 260 | 200 | 170 | |

| H | 1 | – | – | – | 860 | 670 | 550 | 550 | 400 | 310 | – | – | – |

I have read and accepted the Terms & Conditions of use