Product Similar To:

PCD Modular Reamer • R420 • Internal Coolant • Taper Shank • Metric

PCD Modular Reamer • R420 • Internal Coolant

Material Number6761008

ISO Catalog IDR420M22000H6SFMANSI Catalog IDR420M22000H6SFM

- N Non-Ferrous

Reaming: Through Hole

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

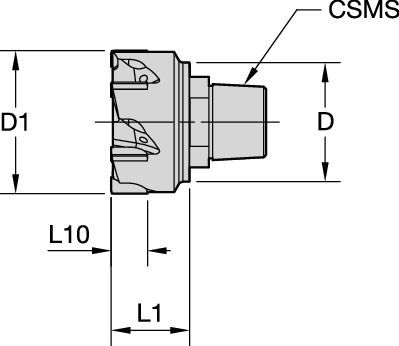

| Material Number | 6761008 |

| ISO Catalog ID | R420M22000H6SFM |

| ANSI Catalog ID | R420M22000H6SFM |

| Grade | KD1415 |

| [D1] Reamer Diameter Minimum | 22 mm |

| [D1] Reamer Diameter Minimum | .8661 in |

| [D] Adapter / Shank / Bore Diameter | 17.5 mm |

| [D] Adapter / Shank / Bore Diameter | .689 in |

| [L1] Gage Length | 15.5 mm |

| [L1] Gage Length | .6102 in |

| [L10] Cutting Edge Length | 7.5 mm |

| [L10] Cutting Edge Length | .2953 in |

| [CSMS] System Size Machine Side | KST175 |

| [Z] Number of Flutes | 4 |

Workpiece Materials

- Non-Ferrous

Uses and application

Reaming: Through Hole

Grades

KD1415

PCD-tip brazed to carbide for general machining of aluminum with a low silicon content, non-ferrous heavy metals, and plastics. KD1415™ can be used at high cutting speeds and for continuous cutting, even where outstanding surface finishes are required. KD1415 is suitable for wet and dry machining.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

| Material |  |  | |||||||||||

| Cutting Speed | Inch | ||||||||||||

| Range | Recommended feed per tooth (IPT = inch/th) | ||||||||||||

| Min | Starting Value | Max | > = .20 | > = .40 | > = .60 | > = 1.00 | > = 1.20 | > = 2.00 | > = 2.80 | max. 4.00 | |||

| N | 1 | 500 | 1200 | 2100 | IPR | .002 – .006 | .003 – .008 | .004 – .010 | .005 – .011 | .005 – .011 | .005 – .011 | .005 – .011 | .005 – .011 |

| 2 | 500 | 1500 | 2000 | IPR | .002 – .006 | .003 – .008 | .004 – .010 | .005 – .011 | .005 – .011 | .005 – .011 | .005 – .011 | .005 – .011 | |

| 3 | 500 | 1300 | 1800 | IPR | .002 – .006 | .003 – .008 | .004 – .010 | .005 – .011 | .005 – .011 | .005 – .011 | .005 – .011 | .005 – .011 | |

| 4 | 300 | 800 | 1100 | IPR | .002 – .006 | .002 – .008 | .004 – .010 | .005 – .011 | .005 – .011 | .005 – .011 | .005 – .011 | .005 – .011 | |

| Material |  |  | |||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended feed per tooth (fz = mm/th) | ||||||||||||

| Min | Starting Value | Max | > = 5,0 | > = 10,0 | > = 16,0 | > = 25,0 | > = 32,0 | > = 50,0 | > = 70,0 | max. 100,0 | |||

| N | 1 | 150 | 350 | 650 | mm/r | 0,06 | 0,08 | 0,10 | 0,12 | 0,12 | 0,12 | 0,12 | 0,12 |

| 2 | 150 | 450 | 600 | mm/r | 0,06 | 0,06 | 0,08 | 0,08 | 0,08 | 0,10 | 0,10 | 0,10 | |

| 3 | 150 | 400 | 550 | mm/r | 0,05 | 0,05 | 0,05 | 0,06 | 0,06 | 0,08 | 0,08 | 0,08 | |

| 4 | 100 | 250 | 350 | mm/r | 0,05 | 0,05 | 0,05 | 0,06 | 0,06 | 0,08 | 0,08 | 0,08 | |

| Material |  |  | |||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended feed per tooth (fz = mm/th) | ||||||||||||

| Min | Starting Value | Max | > = 5,0 | > = 10,0 | > = 16,0 | > = 25,0 | > = 32,0 | > = 50,0 | > = 70,0 | max. 100,0 | |||

| N | 1 | 150 | 350 | 650 | mm/r | 0,06 | 0,08 | 0,10 | 0,12 | 0,12 | 0,12 | 0,12 | 0,12 |

| 2 | 150 | 450 | 600 | mm/r | 0,06 | 0,06 | 0,08 | 0,08 | 0,08 | 0,10 | 0,10 | 0,10 | |

| 3 | 150 | 400 | 550 | mm/r | 0,05 | 0,05 | 0,05 | 0,06 | 0,06 | 0,08 | 0,08 | 0,08 | |

| 4 | 100 | 250 | 350 | mm/r | 0,05 | 0,05 | 0,05 | 0,06 | 0,06 | 0,08 | 0,08 | 0,08 | |

I have read and accepted the Terms & Conditions of use