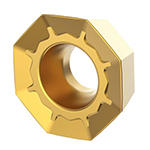

7745VOD04 Series

Elevate your milling capabilities with Kennametal's 7745VOD04 inserts and shell mill tool holders. Precision-engineered for machining materials such as steel, alloyed steel, stainless steel, high-temperature alloys, cast iron, and aluminum alloys, the 7745VOD04 series makes them a top choice for machining component surfaces with scale and irregular stock. With octagonal inserts providing up to eight cost-effective cutting edges, these cutters excel in roughing, semi-finishing, and finishing applications. The robust design is perfect for facing, ramping, pocketing, helical interpolation, and more. Select from Weldon shanks or shell mill bodies, ensuring adaptability to various machining needs.

- P Steel (48)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(48)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(48)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(47)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(47)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(47)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(47)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(47)

- M Stainless Steel (49)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(49)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(49)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(49)

- K Cast Iron (32)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(32)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(32)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(32)

- S High-Temp Alloys (50)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(49)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(49)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(49)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(50)

- H Hardened Materials (2)

- H1Hardened Materials 44-48 HRC(2)

- DE (17)

- GB (13)

Chamfer Milling (29)

Face Milling (29)

Pocket (29)

Pocket Helical (29)

Pocket Milling (29)

Profile Milling (29)

Ramping (29)

Shoulder Bottom Shoulder (26)

Shoulder Milling (29)

Shoulder Roughing (29)

Slot Milling (29)

Slot Side (29)

- 0.984 in(2)

- 1.0 in(1)

- 1.25 in(1)

- 1.26 in(2)

- 1.5 in(2)

- 1.575 in(2)

- 1.969 in(3)

- 2.0 in(2)

- 2.48 in(2)

- 2.5 in(1)

- 3.0 in(2)

- 3.15 in(2)

- 3.938 in(2)

- 4.0 in(2)

- 4.921 in(2)

- 6.299 in(1)

- 25.0 mm(2)

- 25.401 mm(1)

- 31.75 mm(1)

- 32.0 mm(2)

- 38.1 mm(2)

- 40.0 mm(2)

- 50.0 mm(3)

- 50.801 mm(2)

- 63.0 mm(2)

- 63.5 mm(1)

- 76.2 mm(2)

- 80.0 mm(2)

- 100.0 mm(2)

- 101.601 mm(2)

- 125.0 mm(2)

- 160.0 mm(1)

- 33.0 mm(1)

- 33.025 mm(1)

- 33.4 mm(1)

- 39.625 mm(1)

- 40.0 mm(1)

- 40.176 mm(1)

- 45.975 mm(2)

- 48.0 mm(2)

- 58.0 mm(2)

- 58.676 mm(1)

- 59.1 mm(1)

- 60.401 mm(1)

- 71.0 mm(1)

- 71.375 mm(1)

- 71.875 mm(1)

- 83.976 mm(1)

- 84.25 mm(1)

- 88.0 mm(2)

- 108.0 mm(2)

- 109.476 mm(1)

- 109.976 mm(1)

- 133.0 mm(1)

- 133.375 mm(1)

- 168.0 mm(1)

- 1.299 in(1)

- 1.3 in(1)

- 1.315 in(1)

- 1.56 in(1)

- 1.575 in(1)

- 1.582 in(1)

- 1.81 in(2)

- 1.891 in(2)

- 2.283 in(2)

- 2.31 in(1)

- 2.327 in(1)

- 2.378 in(1)

- 2.795 in(1)

- 2.81 in(1)

- 2.83 in(1)

- 3.306 in(1)

- 3.317 in(1)

- 3.465 in(2)

- 4.252 in(2)

- 4.311 in(1)

- 4.33 in(1)

- 5.236 in(1)

- 5.251 in(1)

- 6.614 in(1)

- 3.5 mm(8)

- 3.551 mm(2)

- 7.625 mm(8)

- 8.0 mm(10)

- 10.0 mm(1)

- 0.138 in(8)

- 0.14 in(2)

- 0.3 in(8)

- 0.315 in(10)

- 0.394 in(1)

- 1.26 in(1)

- 1.379 in(1)

- 1.567 in(1)

- 1.575 in(12)

- 1.969 in(10)

- 2.48 in(3)

- 3.74 in(1)

- 32.0 mm(1)

- 35.0 mm(1)

- 39.801 mm(1)

- 40.0 mm(12)

- 50.0 mm(10)

- 63.0 mm(3)

- 95.0 mm(1)

- 42.0 (4)

- 42.3 (1)

- 43.0 (1)

- 87.0 (22)

- 87.632 (1)

- A-Socket Head Cap Screw (20)

- SHCS or RetScrw Or BoltCircle (1)

- Weldon (8)

- 11 (2)

- 12 (1)

- 15 (1)

- 2 (3)

- 3 (3)

- 4 (6)

- 5 (3)

- 6 (4)

- 7 (3)

- 8 (1)

- 9 (2)

- 1.26 in(1)

- 1.379 in(1)

- 1.575 in(8)

- 1.969 in(8)

- 2.48 in(3)

- 3.543 in(1)

- 3.605 in(1)

- 3.781 in(1)

- 3.856 in(1)

- 4.25 in(1)

- 4.331 in(1)

- 5.71 in(1)

- 5.945 in(1)

- 32.0 mm(1)

- 35.0 mm(1)

- 40.0 mm(8)

- 50.0 mm(8)

- 63.0 mm(3)

- 90.0 mm(1)

- 91.575 mm(1)

- 96.0 mm(1)

- 97.95 mm(1)

- 107.95 mm(1)

- 110.0 mm(1)

- 145.0 mm(1)

- 151.0 mm(1)

- 0.0 in(31)

- 0.008 in(32)

- 0.031 in(44)

- 0.047 in(4)

- 0.0 mm(31)

- 0.2 mm(32)

- 0.8 mm(44)

- 1.201 mm(4)

- MP91M (31)

- SC3025 (31)

- SP4019 (2)

- SP6519 (37)

- X500 (37)

- X700 (31)

- R (29)

- N (24)

- 1.4 (1)

- 2.0 (2)

- 2.4 (4)

- 3.0 (4)

- 4.3 (3)

- 6.0 (1)

- 6.1 (4)

- 8.5 (4)

- 12.1 (3)

- 17.0 (3)

- 0.728 in(1)

- 0.768 in(1)

- 0.965 in(2)

- 1.03 in(1)

- 18.5 mm(1)

- 19.5 mm(1)

- 24.5 mm(2)

- 26.151 mm(1)

- O-OCTOGON 135 (24)

- 12.8 mm(14)

- 16.0 mm(10)

- 0.504 in(14)

- 0.63 in(10)

- 4.0 mm(11)

- 5.301 mm(3)

- 6.0 mm(10)

- 0.157 in(11)

- 0.209 in(3)

- 0.237 in(10)

- 41 (9)

- 412 (3)

- 44 (5)

- H W (24)

- E (5)

- M (19)

- CYLINDRICAL (8)

- SHELL MILL (21)

- 12.701 mm(1)

- 16.0 mm(1)

- 19.05 mm(4)

- 20.0 mm(2)

- 22.0 mm(5)

- 25.0 mm(2)

- 25.401 mm(3)

- 27.0 mm(2)

- 31.75 mm(3)

- 32.0 mm(3)

- 40.0 mm(3)

- 0.5 in(1)

- 0.63 in(1)

- 0.75 in(4)

- 0.787 in(2)

- 0.866 in(5)

- 0.984 in(2)

- 1.0 in(3)

- 1.063 in(2)

- 1.25 in(3)

- 1.26 in(3)

- 1.575 in(3)