Product Similar To:

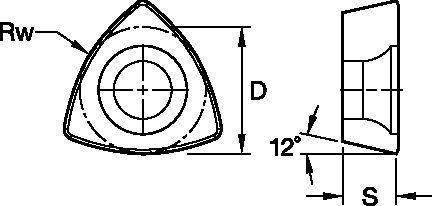

Insert for KenFeed™ Mini • WPGX03...-LD

Indexable Insert • WPGX03...

Material Number2227172

ISO Catalog IDWPGX030204LD080ANSI Catalog IDWPGX030204LD080

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 2227172 |

| ISO Catalog ID | WPGX030204LD080 |

| ANSI Catalog ID | WPGX030204LD080 |

| Grade | KCPK30 |

| [D] Insert IC Size | 5.5 mm |

| [D] Insert IC Size | 0.2165 in |

| [S] Insert Thickness | 2.38 mm |

| [S] Insert Thickness | 0.0937 in |

| [RW] Wiper Radius | 8 mm |

| [RW] Wiper Radius | 0.315 in |

| Cutting Edges per Insert | 3 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

Grades

KCPK30

Coated carbide grade with CVD multilayer (TiN/TiCN/Al2O3) and advanced Beyond™ post-coat treatment. Substrate is very tough. KCPK30 has a wide application area in general and roughing milling of steels and cast irons. Performs best dry, but can also be used wet.

Features and benefits

- Positive single-sided insert for lower cutting forces for high-feed milling process.

- Engineered to run up to 0,05 IPT. Boost productivity in small machines and/or components.

- LD first choice for majority of materials, providing lower cutting forces.

- LN geometry is the first choice for high-strength steel and hard machining up to 55 HRC.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use