Product Similar To:

KenDrill™ SGL • 20 x D • Internal Coolant • Straight Shank • Metric

Solid Carbide Deep Hole Drill for Stainless Steels and High-Temperature Alloys

Material Number6351281

ISO Catalog IDB272Z03000SGLANSI Catalog IDB272Z03000SGL

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Drilling: Stacked Plates

Drilling

Drilling: Inclined Exit

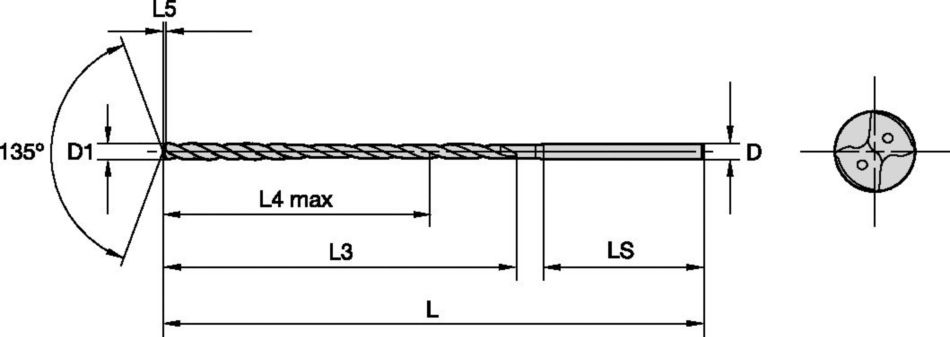

Tool Dimensions: 2flute/4margin/coolant

DIN number 6535

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling: Cross-Hole Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6351281 |

| ISO Catalog ID | B272Z03000SGL |

| ANSI Catalog ID | B272Z03000SGL |

| Grade | KCMS20 |

| [D1] Drill Diameter M | 3 mm |

| [D1] Drill Diameter M | .1181 in |

| [L] Overall Length | 101 mm |

| [L] Overall Length | 3.98 in |

| [L3] Flute Length | 67 mm |

| [L3] Flute Length | 2.64 in |

| [L4] Maximum Drilling Depth | 60 mm |

| [L4] Maximum Drilling Depth | 2.36 in |

| [L5] Drill Point Length | 0.51 mm |

| [L5] Drill Point Length | .02 in |

| [LS] Shank Length | 30 mm |

| [LS] Shank Length | 1.18 in |

| [D] Adapter / Shank / Bore Diameter | 3 mm |

| [D] Adapter / Shank / Bore Diameter | .1181 in |

Workpiece Materials

- Steel

- Stainless Steel

- High-Temp Alloys

Uses and application

Drilling: Stacked Plates

Drilling

Drilling: Inclined Exit

Tool Dimensions: 2flute/4margin/coolant

DIN number 6535

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling: Cross-Hole Drilling

Features and benefits

- HP solid carbide deep-hole drills with through coolant for steel, cast iron, stainless steel, high-temperature alloys, and non-ferrous materials.

- Application-specific SC drill for drilling holes up to 20 x D up to 4x faster than conventional HSS and gun drills.

- Broadest diameter range on the market from .0938–.6299″ (2,383–16mm).

- KMH-point geometry is available as a semi-standard, especially for crankshaft applications.

- KCMS20 grade (B27_SGL) is a monolayer PVD AlTiN coated ultrafine grain carbide with superior surface finish. First choice for deep hole drilling of stainless steel and high-temperature resistant materials. Due to the coatings enhanced high temperature properties this grade can also be applied for MQL applications in steel.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Tolerance

| Tolerans • İnç | ||

| Anma ölçüsü aralığı | D1 Tolerans m7 | D Tolerans h6 |

| .0394–.1181 | .0000/-.0004 | .0000/-.0006 |

| .0002/.0006 | .0000/-.0003 | |

| .0002/.0008 | .0000/-.0004 | |

| .0003/.0010 | .0000/-.0004 | |

| .0003/.0011 | .0000/-.0005 | |

| Tolerans • Metrik | ||

| Anma ölçüsü aralığı | D1 Tolerans m7 | D Tolerans h6 |

| 1–3 | 0,000/-0,010 | 0,000/-0,014 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 | |

Application Data

Deep-Hole Drills • B27_HPG Series • Grade KCPK20™ • Through Coolant • Drill Diameters 3–16mm • Metric

| Malzeme grubu |  |  | |||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | |||

| P | 0 | 100 | 100 | 125 | mm/dev | 0,13 | 0,14 | 0,15 | 0,19 | 0,21 | 0,26 | 0,30 | 0,34 |

| 1 | 90 | 100 | 110 | mm/dev | 0,15 | 0,16 | 0,18 | 0,22 | 0,25 | 0,30 | 0,35 | 0,40 | |

| 2 | 90 | 100 | 110 | mm/dev | 0,15 | 0,16 | 0,18 | 0,22 | 0,25 | 0,30 | 0,35 | 0,40 | |

| 3 | 80 | 95 | 110 | mm/dev | 0,15 | 0,16 | 0,18 | 0,22 | 0,25 | 0,30 | 0,35 | 0,40 | |

| 4 | 80 | 90 | 110 | mm/dev | 0,15 | 0,16 | 0,18 | 0,22 | 0,25 | 0,30 | 0,35 | 0,40 | |

| 5 | 60 | 80 | 90 | mm/dev | 0,03 | 0,04 | 0,05 | 0,05 | 0,08 | 0,11 | 0,12 | 0,14 | |

| 6 | 110 | 150 | 190 | mm/dev | 0,07 | 0,09 | 0,12 | 0,15 | 0,17 | 0,19 | 0,20 | 0,22 | |

| M | 1 | 40 | 50 | 60 | mm/dev | 0,04 | 0,06 | 0,08 | 0,10 | 0,11 | 0,12 | 0,13 | 0,14 |

| 2 | 30 | 40 | 50 | mm/dev | 0,04 | 0,06 | 0,08 | 0,09 | 0,10 | 0,11 | 0,12 | 0,13 | |

| 3 | 30 | 40 | 50 | mm/dev | 0,04 | 0,06 | 0,08 | 0,09 | 0,10 | 0,11 | 0,12 | 0,13 | |

| K | 1 | 80 | 100 | 120 | mm/dev | 0,15 | 0,17 | 0,19 | 0,24 | 0,27 | 0,32 | 0,38 | 0,45 |

| 2 | 80 | 90 | 100 | mm/dev | 0,15 | 0,16 | 0,18 | 0,22 | 0,25 | 0,30 | 0,35 | 0,40 | |

| 3 | 60 | 90 | 120 | mm/dev | 0,15 | 0,16 | 0,18 | 0,22 | 0,25 | 0,30 | 0,35 | 0,40 | |

| Malzeme grubu |  |  | |||||||||||

| Malzeme grubu | Kesme hızı | İnç | |||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 0.551 | 5/8 .625 | |||

| P | 0 | 330 | 330 | 410 | IPR | .005–.006 | .006–.006 | .006–.008 | .008–.010 | .008–.012 | .010–.014 | .012–.016 | .013–.018 |

| 1 | 300 | 330 | 360 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 2 | 300 | 330 | 360 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 3 | 260 | 310 | 360 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 4 | 260 | 300 | 360 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 5 | 200 | 260 | 300 | IPR | .001–.004 | .002–.004 | .002–.004 | .002–.006 | .003–.007 | .004–.008 | .005–.009 | .006–.009 | |

| 6 | 360 | 490 | 620 | IPR | .003–.005 | .004–.004 | .005–.008 | .006–.011 | .007–.013 | .008–.015 | .008–.016 | .009–.017 | |

| M | 1 | 130 | 160 | 200 | IPR | .002–.003 | .002–.005 | .003–.006 | .004–.006 | .004–.006 | .005–.007 | .005–.007 | .006–.008 |

| 2 | 100 | 130 | 160 | IPR | .002–.003 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .004–.006 | .005–.007 | .005–.007 | |

| 3 | 100 | 130 | 160 | IPR | .002–.003 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .004–.006 | .005–.007 | .005–.007 | |

| K | 1 | 260 | 330 | 390 | IPR | .006–.008 | .007–.008 | .008–.010 | .009–.013 | .011–.016 | .013–.018 | .015–.021 | .018–.023 |

| 2 | 260 | 300 | 330 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 3 | 200 | 300 | 390 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

|  | ||||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Malzeme grubu | Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | ||

| P | 0 | 100 | 100 | 125 | mm/dev | 0,13–0,15 | 0,14–0,16 | 0,15–0,21 | 0,19–0,26 | 0,21–0,31 | 0,26–0,36 | 0,30–0,41 | 0,34–0,46 |

| 1 | 90 | 100 | 110 | mm/dev | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 2 | 90 | 100 | 110 | mm/dev | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 3 | 80 | 95 | 110 | mm/dev | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 4 | 80 | 90 | 110 | mm/dev | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 5 | 60 | 80 | 90 | mm/dev | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,12–0,22 | 0,14–0,24 | |

| 6 | 60 | 70 | 80 | mm/dev | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,12–0,22 | 0,14–0,24 | |

| M | 1 | 40 | 50 | 60 | mm/dev | 0,04–0,08 | 0,06–0,12 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | 0,14–0,19 |

| 2 | 30 | 40 | 50 | mm/dev | 0,04–0,08 | 0,06–0,10 | 0,08–0,13 | 0,09–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | |

| 3 | 30 | 40 | 50 | mm/dev | 0,04–0,07 | 0,06–0,10 | 0,08–0,13 | 0,09–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | |

| K | 1 | 80 | 100 | 120 | mm/dev | 0,15–0,19 | 0,17–0,20 | 0,19–0,26 | 0,24–0,32 | 0,27–0,40 | 0,32–0,45 | 0,38–0,52 | 0,45–0,59 |

| 2 | 80 | 90 | 100 | mm/dev | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 3 | 60 | 90 | 120 | mm/dev | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

I have read and accepted the Terms & Conditions of use