Product Similar To:

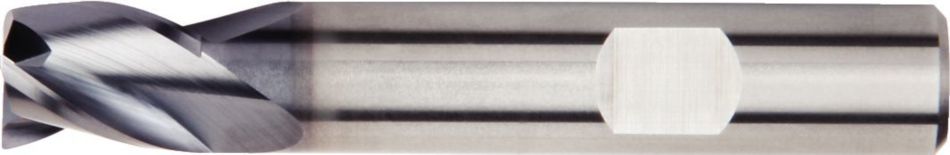

KenCut™ FF • F3AS-DK • Radiused • 3 Flutes • Weldon® Shank • Metric

KenCut™ FF Solid Carbide End Mill for Finishing of Steels, Stainless Steel, Cast Iron

Material Number4046454

ISO Catalog IDF3AS1400BDK35ANSI Catalog IDF3AS1400BDK35

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

DIN number 6527

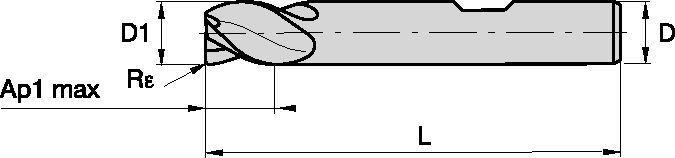

Tool Dimensions: Flute Configuration: 3

Helix Angle: 35°

Corner Style: Corner Radius

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 4046454 |

| ISO Catalog ID | F3AS1400BDK35 |

| ANSI Catalog ID | F3AS1400BDK35 |

| Grade | KCPM15 |

| Adapter Style Machine Side | Weldon |

| [D1] Effective Cutting Diameter | 14 mm |

| [D1] Effective Cutting Diameter | .5512 in |

| [D] Adapter / Shank / Bore Diameter | 14 mm |

| [D] Adapter / Shank / Bore Diameter | .5512 in |

| [AP1MAX] 1st Maximum Cutting Depth | 14 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .5512 in |

| [L] Overall Length | 75 mm |

| [L] Overall Length | 2.952 in |

| [Re] Corner Radius | 0.45 mm |

| [Re] Corner Radius | .0177 in |

| [Z] Number of Flutes | 3 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Uses and application

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

DIN number 6527

Tool Dimensions: Flute Configuration: 3

Helix Angle: 35°

Corner Style: Corner Radius

Features and benefits

- Centre cutting for plunging and ramping operations.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Tolerance

| Parmak freze toleransları | |||

| D1 | Tolerans e8 | D | Tolerans h6 + / - |

| ≤3 | -0,014/-0,028 | ≤3 | +0/-0,006 |

| -0,020/-0,038 | +0/-0,008 | ||

| -0,025/-0,047 | +0/-0,009 | ||

| -0,032/-0,059 | +0/-0,011 | ||

| -0,040/-0,073 | +0/-0,013 | ||

Application Data

|  |  | |||||||||||||

| Dik kenar frezeleme (A) ve Kanal frezeleme (B) | KCPM15 | Çevresel frezeleme (A) için diş başına önerilen ilerleme (fz). Kanal frezeleme (B) için fz %20 azaltılır. | |||||||||||||

| A | B | Kesme hızı; | D1 | ||||||||||||

| Malzeme grubu | ap | ae | ap | Min. | Maks. | mm | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |

| 1 | 0,75 x D | 0,4 x D | 0,5 x D | 150 | 200 | fz | 0,021 | 0,028 | 0,044 | 0,060 | 0,072 | 0,083 | 0,101 | 0,114 | |

| 2 | 0,75 x D | 0,4 x D | 0,5 x D | 140 | 190 | fz | 0,021 | 0,028 | 0,044 | 0,060 | 0,072 | 0,083 | 0,101 | 0,114 | |

| P | 3 | 0,75 x D | 0,4 x D | 0,5 x D | 120 | 160 | fz | 0,018 | 0,023 | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 |

| 4 | 0,75 x D | 0,4 x D | 0,3 x D | 90 | 150 | fz | 0,016 | 0,021 | 0,033 | 0,045 | 0,054 | 0,062 | 0,077 | 0,088 | |

| 5 | 0,75 x D | 0,4 x D | 0,5 x D | 60 | 100 | fz | 0,014 | 0,019 | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | |

| 6 | 0,75 x D | 0,4 x D | 0,3 x D | 50 | 75 | fz | 0,012 | 0,016 | 0,025 | 0,034 | 0,040 | 0,047 | 0,057 | 0,065 | |

| 1 | 0,75 x D | 0,4 x D | 0,5 x D | 80 | 100 | fz | 0,018 | 0,023 | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 | |

| M | 2 | 0,75 x D | 0,4 x D | 0,5 x D | 60 | 80 | fz | 0,014 | 0,019 | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 |

| 3 | 0,75 x D | 0,4 x D | 0,5 x D | 60 | 80 | fz | 0,012 | 0,016 | 0,025 | 0,034 | 0,040 | 0,047 | 0,057 | 0,065 | |

| 1 | 0,75 x D | 0,4 x D | 0,5 x D | 120 | 160 | fz | 0,021 | 0,028 | 0,044 | 0,060 | 0,072 | 0,083 | 0,101 | 0,114 | |

| K | 2 | 0,75 x D | 0,4 x D | 0,5 x D | 110 | 140 | fz | 0,018 | 0,023 | 0,036 | 0,050 | 0,061 | 0,070 | 0,087 | 0,101 |

| 3 | 0,75 x D | 0,4 x D | 0,5 x D | 100 | 130 | fz | 0,014 | 0,019 | 0,029 | 0,040 | 0,048 | 0,056 | 0,070 | 0,081 | |

| H | 1 | 0,75 x D | 0,4 x D | 0,3 x D | 100 | 140 | fz | 0,016 | 0,021 | 0,033 | 0,045 | 0,054 | 0,062 | 0,077 | 0,088 |

I have read and accepted the Terms & Conditions of use