Kennametal New Tooling Innovations Deliver Enhanced Machining Performance & Versatility

Eight new products expand on the manufacturer’s portfolio of solutions in target

end markets including transportation, medical and aerospace.

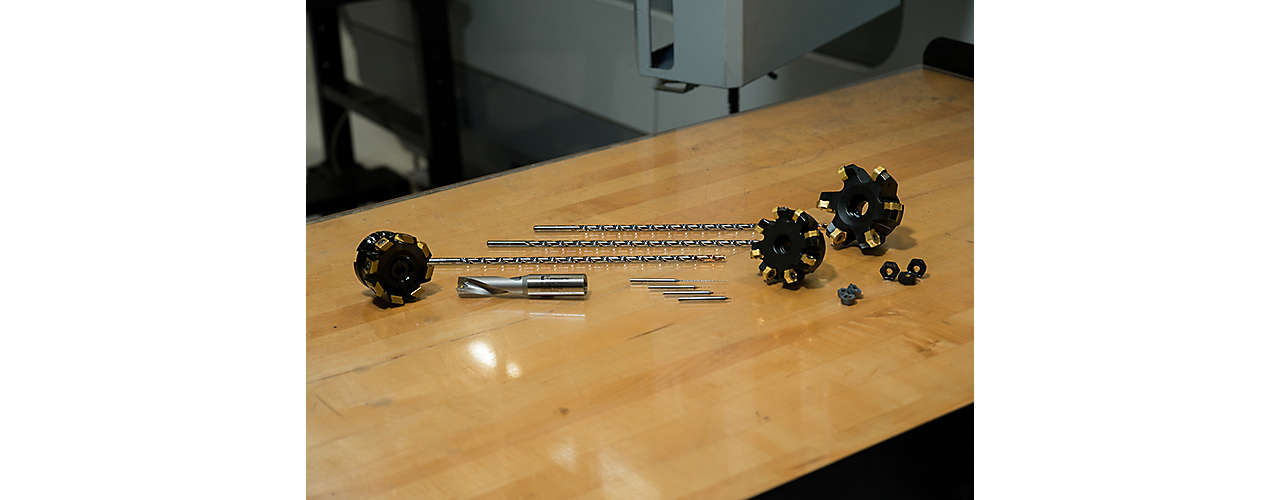

PITTSBURGH, April 3, 2023—Kennametal Inc. is expanding its metal cutting tools and solutions portfolio with eight new products that offer improved performance, wear resistance and productivity for a wide range of applications across end markets including aerospace, medical, energy and transportation as well as general engineering.

“Our latest product expansion includes best-in-class features and advanced technology for metal cutting applications. We’re focused on designing and delivering solutions that combine industry-leading innovation and shop floor perspective to bring new levels of efficiency, productivity and performance to our customers,” said Vice President of Global Product Management Scott Etling.

The launch includes eight products that expand on and support existing platforms in delivering superior performance across multiple applications as well as address common machining challenges:

- Drill Fix PRO™ is an upgrade to Drill Fix—an existing indexable milling platform in the Kennametal product line. Designed for extended tool life and smooth drilling at high metal removal rates, Drill Fix PRO delivers high-volume coolant flow with a wiper included in every outboard insert.

- KenDrill™ Deep HPRis a material-specific, deep-hole drill with broad diameter ranges and length variations. Made specifically for drilling steel and iron, KenDrill Deep HPR boosts performance, productivity and tool life.

- KenDrill™ Micro is Kennametal’s first comprehensive micro drilling portfolio for short- and deep-hole applications. This versatile tooling set offers the best process reliability and longevity in small part machining applications.

- Face milling operations are enhanced with the expansion of Kennametal’s Dodeka™ series, featuring super high positive inserts with 12 true cutting edges per insert.

- Combining proprietary coating technology with next generation wear and oxidation resistance, Kennametal’s new solid end mill grade KCSM15A offers new levels of reliability and output. The new grade launches with the HARVI™ III, HARVI III Aerospace, HARVI II Long and RSM II platforms—proven performers in multiple industries and applications.

- Kennametal’s new stainless steel and high-temp alloy indexable drilling grades KCMS40 and KCMS35 are compatible with the new Drill Fix PRO™ platform and feature higher adhesion wear resistance.

- Complementing another existing platform, Kennametal’s Mill 4™-12KT, are new HD geometry and fine pitch cutters that serve as performance boosters for highly interrupted cuts.

- KenShape™ MaPACS (brazed) and MaxPACS (indexable) countersinks deliver maximum performance for manual CFRP countersinking applications and are the perfect fit for aerospace industry customers focusing on rivet hole drilling in composite and stacked materials.

For more information about new tooling by Kennametal, visit our Featured Innovations Products page.

About Kennametal

With over 80 years as an industrial technology leader, Kennametal Inc. delivers productivity to customers through materials science, tooling and wear-resistant solutions. Customers across aerospace, earthworks, energy, general engineering and transportation turn to Kennametal to help them manufacture with precision and efficiency. Every day approximately 8,700 employees are helping customers in more than 60 countries stay competitive. Kennametal generated $2 billion in revenues in fiscal 2022. Learn more at www.kennametal.com. Follow @Kennametal: Twitter, Instagram, Facebook, LinkedIn and YouTube.