Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Sign Out

Item(s) successfully added to cart

View Cart

View Cart

Turn up your volume for less with our limited-time offers! Shop Now

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Solid End Milling

- /

- High-Performance Solid Carbide End Mills

- /

- PCD End Mills

- /

- KenCut™ AQ • ALSB • Radiused • 4–5 Flutes • 1,25 x D • Internal Coolant • Plain Shank • Metric

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

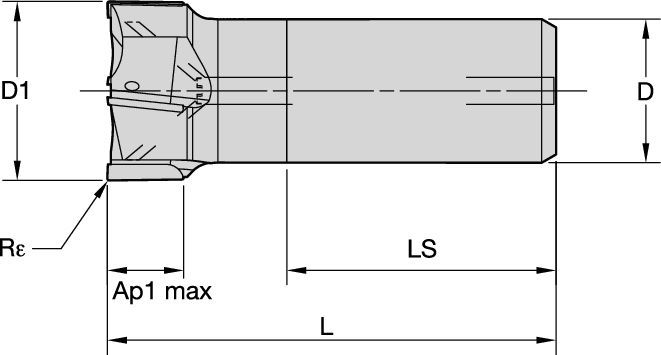

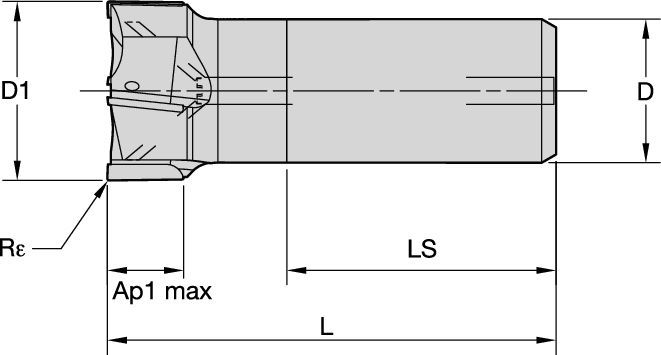

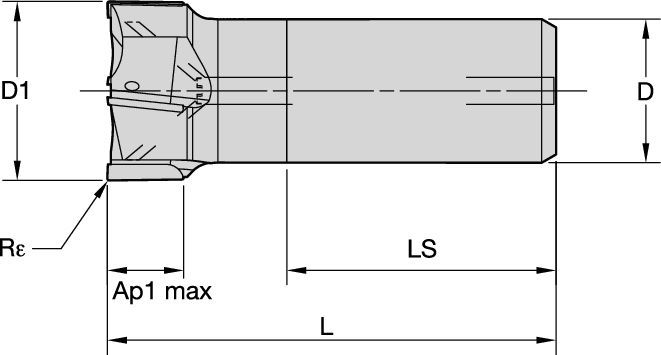

KenCut™ AQ • ALSB • Radiused • 4–5 Flutes • 1,25 x D • Internal Coolant • Plain Shank • Metric

KenCut™ AQ PCD End Mill for Roughing and Finishing of Aluminum

Features and benefits

- End mills with polycrystalline diamond (PCD) for high-speed aluminum machining, reducing maching time drastically.

- PCD end mills provide up to ten times higher productivity compared to solid carbide end mills.

- Minimum quantitiy lubrication ready (MQL Ready).

- Sharp cutting edges and low friction rake surfaces guarantee high quality surface finishes.

Uses and application

Trochoidal Milling

Slotting: Square End

Face Milling

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Side Milling/Shoulder Milling: Roughing

| Malzeme grubu |  |  | KD1410 | Dik kenar frezeleme (A) için diş başına önerilen ilerleme (fz = mm/Diş). Kanal frezeleme (B) için fz %20 azaltılır. | ||||||||

| A | B | Kesme hızı; | D1 | |||||||||

| ap | ae | ap | Min. | Maks. | mm | 25,0 | 32,0 | 40,0 | 50,0 | |||

| N | 1 | L10 | 0,25 x D | 0,5 x L10 | 200 | – | 3000 | Fz | 0,180 | 0,200 | 0,200 | 0,220 |

| 2 | L10 | 0,25 x D | 0,5 x L10 | 200 | – | 3000 | Fz | 0,180 | 0,200 | 0,200 | 0,220 | |

| 3 | L10 | 0,25 x D | 0,5 x L10 | 180 | – | 1400 | Fz | 0,160 | 0,180 | 0,180 | 0,200 | |

| 4 | L10 | 0,25 x D | 0,5 x L10 | 200 | – | 800 | Fz | 0,140 | 0,160 | 0,160 | 0,180 | |

| 5 | L10 | 0,25 x D | 0,5 x L10 | 200 | – | 1000 | Fz | 0,120 | 0,120 | 0,120 | 0,140 | |

| 6 | L10 | 0,25 x D | 0,5 x L10 | 150 | – | 800 | Fz | 0,100 | 0,100 | 0,100 | 0,120 | |

| 7 | L10 | 0,25 x D | 0,5 x L10 | 250 | – | 500 | Fz | 0,100 | 0,100 | 0,100 | 0,120 | |

| Malzeme grubu |  |  | KD1410 | Dik kenar frezeleme (A) için diş başına önerilen ilerleme (fz = mm/Diş). Kanal frezeleme (B) için fz %20 azaltılır. | ||||||||

| A | B | Kesme hızı; | D1 | |||||||||

| ap | ae | ap | Min. | Maks. | mm | 25,0 | 32,0 | 40,0 | 50,0 | |||

| N | 1 | L10 | 0,25 x D | 0,5 x L10 | 200 | – | 3000 | Fz | 0,180 | 0,200 | 0,200 | 0,220 |

| 2 | L10 | 0,25 x D | 0,5 x L10 | 200 | – | 3000 | Fz | 0,180 | 0,200 | 0,200 | 0,220 | |

| 3 | L10 | 0,25 x D | 0,5 x L10 | 180 | – | 1400 | Fz | 0,160 | 0,180 | 0,180 | 0,200 | |

| 4 | L10 | 0,25 x D | 0,5 x L10 | 200 | – | 800 | Fz | 0,140 | 0,160 | 0,160 | 0,180 | |

| 5 | L10 | 0,25 x D | 0,5 x L10 | 200 | – | 1000 | Fz | 0,120 | 0,120 | 0,120 | 0,140 | |

| 6 | L10 | 0,25 x D | 0,5 x L10 | 150 | – | 800 | Fz | 0,100 | 0,100 | 0,100 | 0,120 | |

| 7 | L10 | 0,25 x D | 0,5 x L10 | 250 | – | 500 | Fz | 0,100 | 0,100 | 0,100 | 0,120 | |