Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Hi, Sign In

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

Turn up your volume for less with our limited-time offers! Shop Now

- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Indexable Milling

- /

- High-Feed Series

- /

- KSSM • High-Feed • Beyond BLAST™

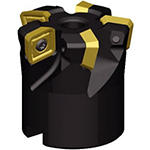

KSSM • High-Feed • Beyond BLAST™

Select Filters

Filters

Filters

View filters in

Metric

Inch

Key Filters

Workpiece Material

Workpiece Material

- P Steel (6)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(6)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(6)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(6)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(6)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(6)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(6)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(6)

- M Stainless Steel (6)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(6)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(6)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(6)

- S High-Temp Alloys (6)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(6)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(6)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(6)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(6)

Applications

Applications

Face Milling (3)

Pocket (3)

Pocket Helical (3)

Pocket Milling (3)

Profile Milling (3)

Ramping (3)

Shoulder Milling (3)

Shoulder Roughing (3)

=

Cutting Diameter

Cutting Diameter

- 1.135 in(1)

- 1.182 in(1)

- 4.054 in(1)

Cutting Diameter MinEnter ValuetoCutting Diameter MaxCutting Diameter

=

Cutting Diameter

Cutting Diameter

- 28.826 mm(1)

- 30.026 mm(1)

- 102.976 mm(1)

Cutting Diameter MinEnter ValuetoCutting Diameter MaxCutting Diameter

=

Maximum Cutting Diameter

Maximum Cutting Diameter

- 50.801 mm(1)

- 52.0 mm(1)

- 125.0 mm(1)

Maximum Cutting Diameter MinEnter ValuetoMaximum Cutting Diameter MaxMaximum Cutting Diameter

=

Maximum Cutting Diameter

Maximum Cutting Diameter

- 2.0 in(1)

- 2.047 in(1)

- 4.921 in(1)

Maximum Cutting Diameter MinEnter ValuetoMaximum Cutting Diameter MaxMaximum Cutting Diameter

=

Cutting Length

Cutting Length

- 1.651 mm(3)

Cutting Length MinEnter ValuetoCutting Length MaxCutting Length

=

Cutting Length

Cutting Length

- 0.065 in(3)

Cutting Length MinEnter ValuetoCutting Length MaxCutting Length

=

Reach

Reach

- 1.75 in(1)

- 1.969 in(1)

- 2.48 in(1)

Reach MinEnter ValuetoReach MaxReach

=

Reach

Reach

- 44.45 mm(1)

- 50.0 mm(1)

- 63.0 mm(1)

Reach MinEnter ValuetoReach MaxReach

=

Tool Cutting Edge Angle

Tool Cutting Edge Angle

- 10.0 (3)

Tool Cutting Edge Angle MinEnter ValuetoTool Cutting Edge Angle MaxTool Cutting Edge Angle

Connection Style

Connection Style

- A-Socket Head Cap Screw (2)

- KL Screw (1)

Number of Flutes

Number of Flutes

- 12 (1)

- 5 (2)

Internal Coolant Capability

Internal Coolant Capability

=

Over All Length [L]

Over All Length [L]

- 1.75 in(1)

- 1.969 in(1)

- 2.48 in(1)

Over All Length [L] MinEnter ValuetoOver All Length [L] MaxOver All Length [L]

=

Over All Length [L]

Over All Length [L]

- 44.45 mm(1)

- 50.0 mm(1)

- 63.0 mm(1)

Over All Length [L] MinEnter ValuetoOver All Length [L] MaxOver All Length [L]

Application

Hand Of Tool

Hand Of Tool

- R (3)

Wiper Insert

Wiper Insert

- N (3)

=

Maximum Ramp Angle

Maximum Ramp Angle

- 0.59 (1)

- 1.97 (1)

- 2.05 (1)

Maximum Ramp Angle MinEnter ValuetoMaximum Ramp Angle MaxMaximum Ramp Angle

Front-End

Center Cutting

Center Cutting

Insert Geometry

Shape

Shape

- S-SQUARE 90 (3)

=

Insert IC Size

Insert IC Size

- 14.0 mm(3)

Insert IC Size MinEnter ValuetoInsert IC Size MaxInsert IC Size

=

Insert IC Size

Insert IC Size

- 0.551 in(3)

Insert IC Size MinEnter ValuetoInsert IC Size MaxInsert IC Size

=

Cutting Edge Length

Cutting Edge Length

- 14.0 mm(3)

Cutting Edge Length MinEnter ValuetoCutting Edge Length MaxCutting Edge Length

=

Cutting Edge Length

Cutting Edge Length

- 0.551 in(3)

Cutting Edge Length MinEnter ValuetoCutting Edge Length MaxCutting Edge Length

Chip Breaker CBMD

Chip Breaker CBMD

- GD2 (1)

- GN (2)

Cutting Tool Material

Cutting Tool Material

- H W (3)

Tolerance Class

Tolerance Class

- C (3)

Back-End

Connection Type

Connection Type

- SHELL MILL (3)

=

Back-End Diameter

Back-End Diameter

- 19.075 mm(1)

- 22.0 mm(1)

- 40.0 mm(1)

Back-End Diameter MinEnter ValuetoBack-End Diameter MaxBack-End Diameter

=

Back-End Diameter

Back-End Diameter

- 0.751 in(1)

- 0.866 in(1)

- 1.575 in(1)

Back-End Diameter MinEnter ValuetoBack-End Diameter MaxBack-End Diameter

No filters matching ""