Product Similar To:

S2S Weldon Shank • Inch

CTR • Counterbore

Material Number1992698

ISO Catalog IDCBT1625RW100N3ANSI Catalog IDCBT1625RW100N3

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

Flood Coolant: Drilling

Shank - Cylindrical Weldon

Counter Boring

Flute Configuration: 2

Flute Configuration: 3

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 1992698 |

| ISO Catalog ID | CBT1625RW100N3 |

| ANSI Catalog ID | CBT1625RW100N3 |

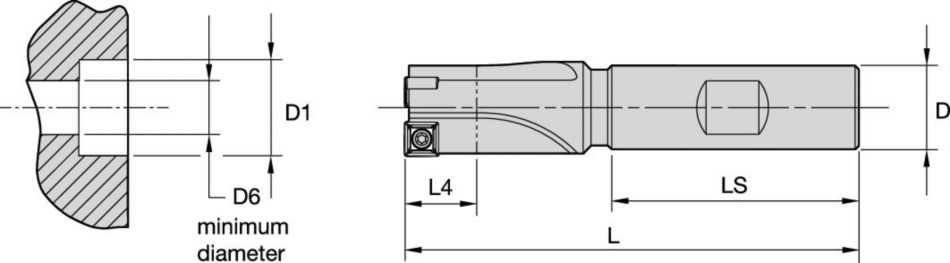

| [D1] Drill Diameter M | 41.275 mm |

| [D1] Drill Diameter M | 1.625 in |

| Drill Diameter Tol. Min | -0.15 mm |

| Drill Diameter Tol. Min | -0.006 in |

| Drill Diameter Tol. Max | 0.15 mm |

| Drill Diameter Tol. Max | .006 in |

| [D] Adapter / Shank / Bore Diameter | 25.4 mm |

| [D] Adapter / Shank / Bore Diameter | 1 in |

| Pre Machined Hole Diameter [D6] | 26.187 mm |

| Pre Machined Hole Diameter [D6] | 1.061 in |

| [L] Overall Length | 114.31 mm |

| [L] Overall Length | 4.5 in |

| [L4] Maximum Drilling Depth | 25.4 mm |

| [L4] Maximum Drilling Depth | 1 in |

| [LS] Shank Length | 58.4 mm |

| [LS] Shank Length | 2.299 in |

| Gage Insert | SPHX120404R. |

| Number of Insert Cutting Diameter 1 | 3 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

Uses and application

Flood Coolant: Drilling

Shank - Cylindrical Weldon

Counter Boring

Flute Configuration: 2

Flute Configuration: 3

Features and benefits

- CTR Counterboring Tools are designed for high-production screw-head counterbores and similar counterboring operations.

- Extremely unequal insert positioning and flutes.

- S2 S inserts reduct additional drill operations to achieve a precise 90° bottom.

- Counterboring tool shipped with insert screws and Torx wrench.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Speeds & Feeds

| Material | Cutting Speed | Metric | |||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | SPHX06... Ø 15-22 | SPHX07 Ø 18-26 | SPHX09 Ø 23-37 | SPHX12 Ø 24-47 | |||||||

| P | 1 | 100 | 140 | 180 | mm/r | 0,19 | 0,31 | 0,23 | 0,33 | 0,24 | 0,38 | 0,3 | 0,5 |

| 2 | 90 | 125 | 160 | mm/r | 0,19 | 0,31 | 0,23 | 0,33 | 0,24 | 0,38 | 0,3 | 0,5 | |

| 3 | 80 | 110 | 140 | mm/r | 0,17 | 0,28 | 0,21 | 0,30 | 0,22 | 0,35 | 0,27 | 0,45 | |

| 4 | 70 | 100 | 120 | mm/r | 0,16 | 0,26 | 0,19 | 0,28 | 0,20 | 0,32 | 0,25 | 0,42 | |

| 5 | 60 | 85 | 100 | mm/r | 0,15 | 0,24 | 0,18 | 0,25 | 0,18 | 0,29 | 0,23 | 0,38 | |

| 6 | 50 | 70 | 90 | mm/r | 0,15 | 0,24 | 0,18 | 0,25 | 0,18 | 0,29 | 0,23 | 0,38 | |

| M | 1 | 60 | 70 | 90 | mm/r | 0,11 | 0,21 | 0,14 | 0,24 | 0,16 | 0,26 | 0,18 | 0,33 |

| 2 | 50 | 60 | 80 | mm/r | 0,11 | 0,21 | 0,14 | 0,24 | 0,16 | 0,26 | 0,18 | 0,33 | |

| 3 | 40 | 50 | 70 | mm/r | 0,09 | 0,17 | 0,11 | 0,19 | 0,13 | 0,21 | 0,14 | 0,26 | |

| K | 1 | 100 | 160 | 240 | mm/r | 0,28 | 0,52 | 0,35 | 0,65 | 0,35 | 0,65 | 0,42 | 0,78 |

| 2 | 80 | 120 | 160 | mm/r | 0,25 | 0,47 | 0,32 | 0,59 | 0,32 | 0,59 | 0,38 | 0,71 | |

| 3 | 70 | 100 | 130 | mm/r | 0,23 | 0,43 | 0,29 | 0,54 | 0,29 | 0,54 | 0,35 | 0,65 | |

| N | 1 | 160 | 240 | 300 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 |

| 2 | 160 | 220 | 280 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| 3 | 150 | 200 | 250 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| 4 | 120 | 180 | 240 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| 5 | 160 | 240 | 300 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| 6 | 200 | 300 | 400 | mm/r | 0,06 | 0,14 | 0,26 | 0,33 | 0,28 | 0,35 | 0,34 | 0,46 | |

| S | 1 | 30 | 40 | 60 | mm/r | 0,14 | 0,18 | 0,17 | 0,21 | 0,19 | 0,23 | 0,21 | 0,29 |

| 2 | 25 | 35 | 50 | mm/r | 0,13 | 0,16 | 0,15 | 0,19 | 0,17 | 0,21 | 0,19 | 0,26 | |

| 3 | 20 | 30 | 40 | mm/r | 0,11 | 0,14 | 0,13 | 0,16 | 0,15 | 0,18 | 0,16 | 0,22 | |

| 4 | 20 | 25 | 35 | mm/r | 0,09 | 0,12 | 0,11 | 0,14 | 0,13 | 0,15 | 0,14 | 0,19 | |

| Material | Cutting Speed | Inch | |||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | SPHX06... Ø 15-22 | SPHX07 Ø 18-26 | SPHX09 Ø 23-37 | SPHX12 Ø 24-47 | |||||||

| P | 1 | 328 | 459 | 590 | IPR | 0.007 | 0.012 | 0.009 | 0.013 | 0.009 | 0.015 | 0.012 | 0.020 |

| 2 | 295 | 410 | 525 | IPR | 0.007 | 0.012 | 0.009 | 0.013 | 0.009 | 0.015 | 0.012 | 0.020 | |

| 3 | 262 | 361 | 459 | IPR | 0.007 | 0.011 | 0.008 | 0.012 | 0.009 | 0.014 | 0.011 | 0.018 | |

| 4 | 230 | 328 | 393 | IPR | 0.006 | 0.010 | 0.008 | 0.011 | 0.008 | 0.012 | 0.010 | 0.016 | |

| 5 | 197 | 279 | 328 | IPR | 0.006 | 0.009 | 0.007 | 0.010 | 0.007 | 0.012 | 0.009 | 0.015 | |

| 6 | 164 | 230 | 295 | IPR | 0.006 | 0.009 | 0.007 | 0.010 | 0.007 | 0.012 | 0.009 | 0.015 | |

| M | 1 | 197 | 230 | 295 | IPR | 0.004 | 0.008 | 0.006 | 0.009 | 0.006 | 0.010 | 0.007 | 0.013 |

| 2 | 164 | 197 | 262 | IPR | 0.004 | 0.008 | 0.006 | 0.009 | 0.006 | 0.010 | 0.007 | 0.013 | |

| 3 | 131 | 164 | 230 | IPR | 0.003 | 0.007 | 0.004 | 0.008 | 0.005 | 0.008 | 0.006 | 0.010 | |

| K | 1 | 328 | 525 | 787 | IPR | 0.011 | 0.020 | 0.014 | 0.026 | 0.014 | 0.026 | 0.017 | 0.031 |

| 2 | 262 | 393 | 525 | IPR | 0.010 | 0.019 | 0.013 | 0.023 | 0.013 | 0.023 | 0.015 | 0.028 | |

| 3 | 230 | 328 | 426 | IPR | 0.009 | 0.017 | 0.011 | 0.021 | 0.011 | 0.021 | 0.014 | 0.026 | |

| N | 1 | 525 | 787 | 984 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 |

| 2 | 525 | 721 | 918 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| 3 | 492 | 656 | 820 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| 4 | 393 | 590 | 787 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| 5 | 525 | 787 | 984 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| 6 | 656 | 984 | 1311 | IPR | 0.002 | 0.006 | 0.010 | 0.013 | 0.011 | 0.014 | 0.013 | 0.018 | |

| S | 1 | 98 | 131 | 197 | IPR | 0.006 | 0.007 | 0.007 | 0.008 | 0.007 | 0.009 | 0.008 | 0.011 |

| 2 | 82 | 115 | 164 | IPR | 0.005 | 0.006 | 0.006 | 0.008 | 0.007 | 0.008 | 0.008 | 0.010 | |

| 3 | 66 | 98 | 131 | IPR | 0.004 | 0.005 | 0.005 | 0.006 | 0.006 | 0.007 | 0.006 | 0.009 | |

| 4 | 66 | 82 | 115 | IPR | 0.004 | 0.005 | 0.004 | 0.006 | 0.005 | 0.006 | 0.006 | 0.008 | |

I have read and accepted the Terms & Conditions of use