Product Similar To:

Straight Shank Synchro Plus • Metric

Straight Shank Synchro Plus™

Material Number5525781

ISO Catalog IDSS25SYTER20073MANSI Catalog IDSS25SYTER20073M

Shank - Cylindrical Whistle Notch 2°

Shank - Cylindrical Weldon 2 Flat

Tapping: Through Coolant

ER Collet

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 5525781 |

| ISO Catalog ID | SS25SYTER20073M |

| ANSI Catalog ID | SS25SYTER20073M |

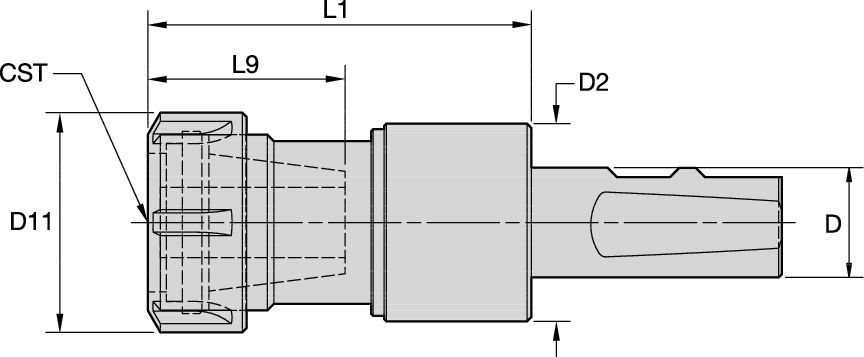

| [CST] Catalog Collet Series | ER20 |

| Tap Range | M4.5 - M12 mm |

| Tap Range | in |

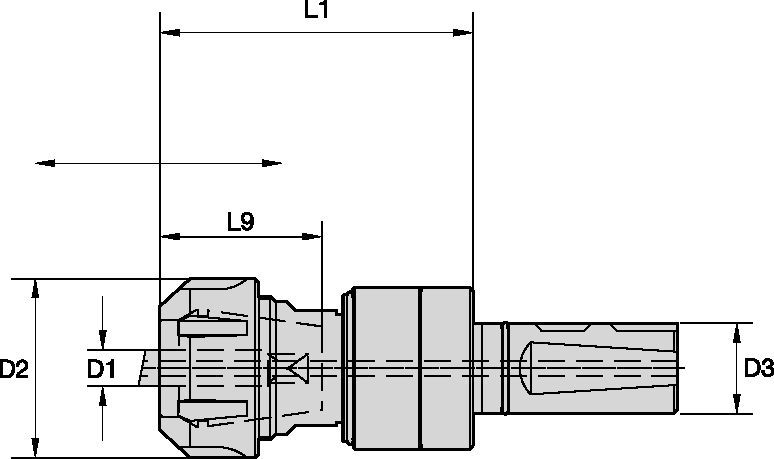

| [D] Adapter / Shank / Bore Diameter | 25 mm |

| [D] Adapter / Shank / Bore Diameter | .9843 in |

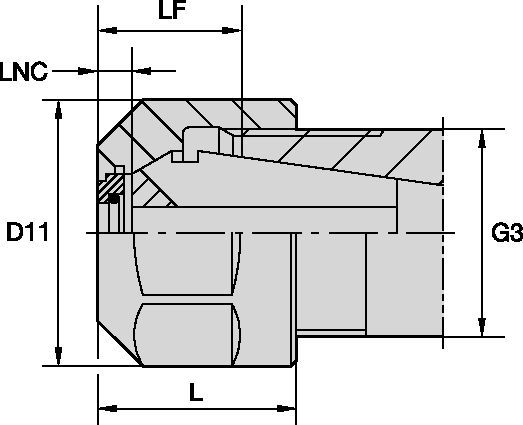

| [D11] Lock Nut Diameter | 34 mm |

| [D11] Lock Nut Diameter | 1.338 in |

| [D2] Body Diameter 1 Workpiece Side | 34 mm |

| [D2] Body Diameter 1 Workpiece Side | 1.338 in |

| [L1] Gage Length | 76.6 mm |

| [L1] Gage Length | 3.015 in |

| [L9] Clamping Length | 45 mm |

| [L9] Clamping Hole Length | 1.772 in |

| Torque Catalog Newton Meters | 32 |

| Torque Catalog Foot Pounds | 23 |

Uses and application

Shank - Cylindrical Whistle Notch 2°

Shank - Cylindrical Weldon 2 Flat

Tapping: Through Coolant

ER Collet

Features and benefits

- Designed to optimize tool life in synchronous tapping, first choice for rotating tapping applications

- Reduces axial cutting forces up to 50%

- Modular design increases application flexibility by working with existing end mill and whistle notch adapters

- Coolant through capability up to 50 bar leads to better tool life

- Uses standard ER tap collets for reliable and repeatable production processes

- For use with taps from 4 - 20 mm (3/16 – ½ inch)

- Tap follows its own lead into the hole instead of being forced by the machine spindle

- 3 micron run-out

- Reinforced outer wall for the collet seat

- Balanced nut & assembly to G2.5 at 25,000 rpm

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use