Product Similar To:

KSSM 90° End Mill SD12 • Metric

Roughing Flat Bottom Indexable

Material Number5517370

ISO Catalog IDFBI68L170SD12F6ANSI Catalog IDFBI68L170SD12F6

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: Flat Bottom

Drilling: Convex

Plunge Milling

Milling - Through Coolant

Counter Boring

Drilling: Concave

Chain Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 5517370 |

| ISO Catalog ID | FBI68L170SD12F6 |

| ANSI Catalog ID | FBI68L170SD12F6 |

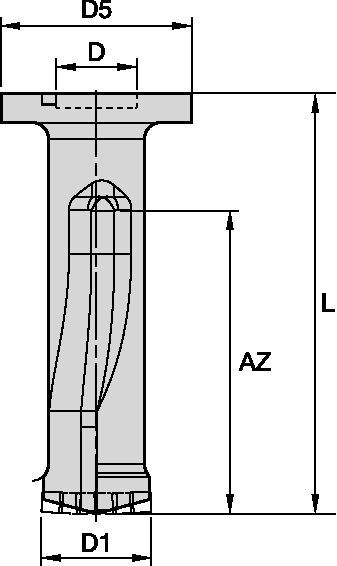

| [D1] Effective Cutting Diameter | 68 mm |

| [D1] Effective Cutting Diameter | 2.677 in |

| [D5] Body Diameter Machine Side | 118 mm |

| [D5] Body Diameter Machine Side | 4.646 in |

| [D] Adapter / Shank / Bore Diameter | 50.012 mm |

| [D] Adapter / Shank / Bore Diameter | 1.969 in |

| [L] Overall Length | 260 mm |

| [L] Overall Length | 10.236 in |

| [AZ] Maximum Plunge Depth | 169 mm |

| [AZ] Maximum Plunge Depth | 6.668 in |

| Number of Inserts | 3 |

| Number of Center Cutting Edges | 1 |

| Weight Kilograms | 4.95 |

| Max RPM | 4683 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

Uses and application

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: Flat Bottom

Drilling: Convex

Plunge Milling

Milling - Through Coolant

Counter Boring

Drilling: Concave

Chain Drilling

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

| Material Group | Light | General | Heavy | |||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1 | ||||||

| P3 | ||||||

| P5 | .S..GDZ | KCPK30 | .E..HPZ | KCPM20 | .S..HPZ | KCPM20 |

| M1 | .E..GDZ | KC725M | .S..GDZ | KC725M | .E..HPZ | KCPK30 |

| M3 | .S..GDZ | KCPK30 | .E..HPZ | KCPK30 | .S..HPZ | KCPK30 |

| K1 | ||||||

| K3 | ||||||

| N1 | ||||||

| N3 | ||||||

| S1 | .E..GDZ | KC725M | .S..GDZ | KC725M | .E..HPZ | KC522M |

| S3 | .S..GDZ | KC725M | .E..HPZ | KC725M | .S..HPZ | KC725M |

| S4 | .E..HPZ | KC725M | .S..HPZ | KC725M | ||

| H1 | ||||||

Feeds

Recommended Starting Feeds [mm]

| Insert Geometry | Programmed Feed per Tooth (fz) at a % of Radial Depth of Cut (ae) | Insert Geometry | ||

| 50–100% | ||||

| All Inserts | 0,004 | 0,010 | 0,016 | All Inserts |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [m/min]

| Material Group | KC522M | KC725M | KCPK30 | KCSM30 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | 200 | 150 | 120 | 160 | 120 | 95 | – | – | – | – | – | – | |

| M | 1 | 245 | 215 | 200 | 205 | 180 | 165 | – | – | – | – | – | – |

| 2 | 225 | 190 | 160 | 185 | 160 | 130 | – | – | – | – | – | – | |

| 3 | 170 | 145 | 115 | 140 | 120 | 95 | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 50 | 45 | 35 | 35 | 30 | – | – | – | – | – | – | – |

| 2 | 50 | 45 | 35 | 30 | 30 | – | – | – | – | – | – | – | |

| 3 | 60 | 50 | 35 | 40 | 40 | – | – | – | – | – | – | – | |

| 4 | 85 | 60 | 45 | 50 | 45 | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use