Manufacturers are constantly being challenged to reduce their carbon footprint and improve efficiency. With Electric Vehicles (EV) revolutionizing the automotive industry, a crucial aspect of this transformation lies in the development of EV components, enabling metalworking manufacturers to build advanced, reliable, and eco-friendly automobiles. Here, we’ll dive into the various components used in EVs and the pivotal role played by aluminum in this industry. Additionally, we will explore innovative tooling to meet the growing demands of the EV market.

What’s the difference between EV and E-Mobility?

In order for us to delve into EVs and discuss sustainable transportation, we should mention the terms electric vehicle and E-mobility are often used interchangeably. Though EVs are a fundamental component, E-mobility encompasses a broader scope of sustainable transportation solutions.

EV refers to vehicles that are powered by electricity instead of traditional Internal Combustion Engines (ICE). They are propelled by electric motors, which draw energy from rechargeable batteries. These batteries store the energy which is used to power the vehicle and move.

EVs come in various forms including:

Battery Electric Vehicles (BEVs) which rely only on electric power, drawing energy from the battery.

Plug-In Hybrid Electric Vehicles (PHEVs) combine an electric motor and an internal combustion engine, offering a limited electric range.

Hybrid Electric Vehicles (HEVs) which primarily use an internal combustion engine but feature an electric motor that assists movement.

E-mobility represents a broader concept that goes beyond electric vehicles. It’s a shift designed to revolutionize the manufacturing processes and transportation. It represents a comprehensive approach to sustainable transportation that not only includes electric vehicles, but electric charging infrastructure, renewable energy integration, and smart mobility solutions. E-mobility seeks to transform the entire transportation ecosystem into a cleaner and more efficient mode of transportation.

The Effect of Electric Vehicles on Metalworking

As the EV market continues to expand, the manufacturing sector plays a vital role in shaping the future of transportation. A critical aspect of this transformation lies in the development of electric vehicle components, enabling manufacturers to build advanced, reliable, and eco-friendly automobile

EVs have a profound impact on the manufacturing sector in several ways:

Transformation of Production Processes: EVs require different manufacturing processes compared to traditional internal combustion engine (ICE) vehicles. If they haven’t already, manufacturing facilities will have to invest in new equipment, technologies, and employee training to support the production of EVs.

Shift in Supply Chains: Manufacturers may have to establish new partnerships and secure a reliable supply of key components for items such as batteries and electric drivetrain systems. Ensuring a stable and sustainable supply chain is essential to support the growing demand for EVs.

Technological Advancements: The rise of EVs encourage technological advancements. Additive Manufacturing (3D Printing): for example, has gained traction, allowing manufacturers to create complex geometries and lightweight structures. This technique enables rapid prototyping, customization, and cost-effective production of components.

Job Creation and Workforce Skills: EV manufacturing creates new job opportunities and requires a workforce with specialized skills. Training programs and upskilling initiatives to develop a skilled workforce capable of supporting EV production are imperative for success.

Manufacturing Benefits of Electric Vehicles

By embracing the components and manufacturing techniques specific to electric vehicles there can be substantial cost-saving advantages:

Reduced Material Costs: Electric vehicle components often utilize lightweight materials like aluminum which plays a large role in electric vehicles. By reducing the material weight used, the vehicle will go farther and reduce material costs while still maintaining structural integrity and performance. Additive manufacturing and advanced forming methods also allow for more efficient use of materials, minimizing waste.

Streamlined Production Processes: Electric vehicle manufacturing often involves advanced automation and robotics, leading to streamlined and efficient production processes. Automated assembly lines can perform repetitive tasks with precision and consistency along with advanced simulation and modeling techniques can optimize designs and minimize errors -- leading to more efficient production and cost savings.

Lower Energy Consumption: EV manufacturing facilities can benefit from reduced energy consumption compared to traditional internal combustion engine (ICE) vehicle production. This is because electric vehicles require fewer manufacturing steps, such as complex engine assembly and exhaust system installation. This in turn reduces energy costs and offers long-term savings.

Lifecycle Cost Reduction: EVs generally require less maintenance due to fewer moving parts and reduced wear and tear on components like brakes. This translates to reduced maintenance and servicing expenses for manufacturers.

Scaling Production: As the demand for EVs continues to rise globally, scaling the production process allows manufacturers to achieve cost savings and potentially pass on the savings to consumers, making electric vehicles more affordable and attractive in the market.

Key Tools and Components for Building Electric Vehicles

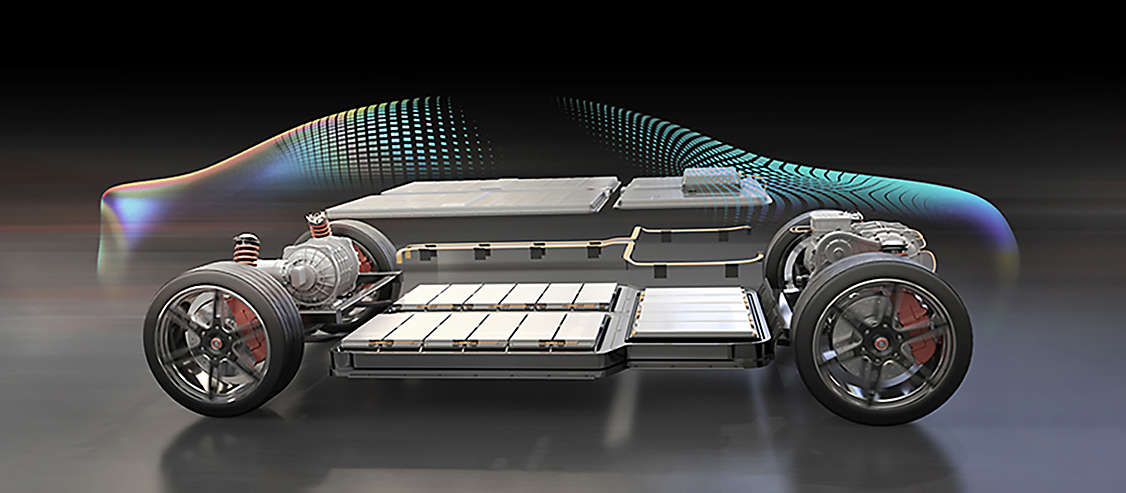

There are several parts that make up an electric vehicle. Here, we discuss some of the key structural components and tools that can be used to engineer an electric vehicle.

Aluminum housings and covers play a crucial role in the development of electric vehicles. Lightweight aluminum enables weight reduction while maintaining the strength of the housing and covers. Aluminum's excellent thermal conductivity contributes to efficient heat dissipation, ensuring optimal performance of electric vehicle components. There are several tools to support the engineering process of this equipment. For example, manufacturers can leverage Kennametal’s PCD tools for aluminum machining or theeBore™ digital fine boring system when working on thin walls.

Battery housings are at the heart of any electric vehicle is its battery and ensuring its safety is extremely important. Battery housings, typically made of lightweight materials, are designed to protect the battery cells from external elements and impacts. They often incorporate cooling systems to maintain optimum battery temperature. In order to make sure these battery housings are manufactured at the highest quality, manufacturers can use tools like Kennametal’s KOR5DA for milling aluminum.

Structural components support the weight of the battery and provide a safe and rigid structure for the EV, manufacturers employ various high-strength materials. These components can include the vehicle's chassis, body panels, and other structural elements, enhancing both performance and safety.

Gears, rotors, and shafts are responsible for transmitting power from the electric motor to the wheels, enabling efficient torque delivery and smooth acceleration. Kennametal’s KENGold™ CVD coated inserts andhigh-performance solid carbide drillsfor deep hole drilling can support the manufacturing of these vital EV parts.

Carbon Fiber-Reinforced Plastic (CFRP) Components have gained popularity in EV and are used to construct body panels, hoods, and roof modules. The use of CFRP tooling can enhance energy efficiency and potentially extend the vehicle's range. Kennametal offers CFRPKenTIP™ FS for modular drilling systems and inserts.

Components of an Electric Vehicle

Summary

By embracing the EV transformation in the automotive industry and meeting the demands for innovative solutions, metalworking manufacturers can benefit from the newest technological advances while at the same time reducing production costs and helping the environment. For more information on EV tooling visit Kennametal’s E-mobility page.

Related Articles

- Tips to Reduce Waste in MachiningWould you like to be more cost-effective when machining? Find out some helpful tips on how to reduce waste and save on production costs.Would you like to be more cost-effective when machining? Find out some helpful tips on how to reduce waste and save on production costs.

- Micromachining: Exploring the Growth of Medical InnovationExplore micromachining and its relation to medical devices, the tools and materials used, and why manufacturing plays a vital role in this area.Explore micromachining and its relation to medical devices, the tools and materials used, and why manufacturing plays a vital role in this area.

- Buying Guide: Composite Materials Machining SolutionsWhen manufacturing composite materials, it is crucial to use top-notch equipment and techniques. Shop Kennametal's specialized tooling for composites now.When manufacturing composite materials, it is crucial to use top-notch equipment and techniques. Shop Kennametal's specialized tooling for composites now.

- Choose the Right Toolholder for Your Operations Choosing the right toolholder is critical for achieving precise and efficient machining results. Explore the fundamentals of toolholders and find out what you should know before choosing the right one for your operations.Choosing the right toolholder is critical for achieving precise and efficient machining results. Explore the fundamentals of toolholders and find out what you should know before choosing the right one for your operations.