How to Buy Crusher Bits for Underground Mining

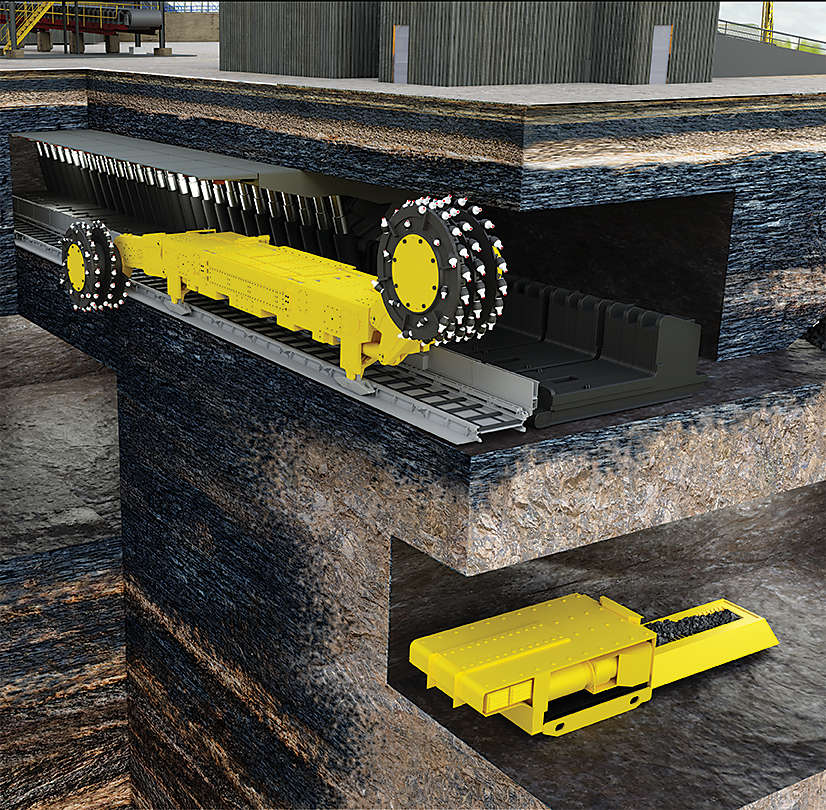

Underground mining operations require specialized equipment to extract minerals and ores from deep within the earth. One of the most important pieces of equipment used in these operations is the crusher tooling cutter. These high-performance tools are used to crush various types of materials to facilitate their extraction. If you’re searching for underground mining conical bits for your crusher, there are a few key things to consider before making a purchase.

Determine Your Crusher Bit Needs

Buying cutting bits for underground mining crusher requires some research and understanding of the different types of bits available. Here are some steps you can follow to buy cutting bits for underground mining crusher:

Identify the type of crusher: Different crushers require different cutting bits. For example, conical bits for track-mounted Continuous Miner machines are perfect for use in tough conditions and restricted spaces when scraping coal. Identify the type of crusher you have to ensure you buy the right crusher bits.

Determine the application: Consider the rock hardness and the type of material you will be cutting to determine the type of cutting bit you need. Some cutting bits are designed for hard rock, while others are better suited for soft rock.

Consider Performance: Crusher bits can vary in performance, and it's essential to prioritize quality over price to ensure your cutting bits don’t wear down too fast and perform at their highest capabilities.

Consult with Experts: If you're unsure about which crusher conical bit to buy or have any questions, consult with experts in the field. Experts in the field can provide valuable advice and help you make an informed decision.

How to Select a Crusher Conical Bit

Selecting the right crusher depends on several factors, including the type of material being crushed, the desired particle size, and the capacity requirements. Here are some steps to help you choose the right crusher tooling:

Shank Size: The shank size refers to the diameter of the shank that connects the crusher to the drilling machine. Make sure to select a crusher with a shank size that matches your machine.

Gauge Length: The gage length is the distance from the end of the crusher to the cutting point. The gage length should be selected based on the thickness of the material being crushed. For thinner materials, a shorter gage length is preferred.

Identify Cutting Condition: The cutting condition refers to the type of material being crushed and the level of difficulty of the job. Light-cutting conditions involve softer materials and require less force, while heavy-cutting conditions involve harder materials and require more force.

Insert Type: Choose the insert type based on the cutting condition. A plug or bullet nose insert is suitable for light to medium cutting conditions, while a narrow bottom insert is better for heavy cutting conditions.

Body Style: The body style of the crusher affects its life and penetrability. A heavy or standard body style is recommended for extended life, while a slim or finned body style is better for improved penetration.

Safety and Maintenance

Safety is one of the most important factors to help prevent unnecessary injuries and improve workforce productivity. When purchasing underground mining crushers and tooling systems, ensure regular maintenance and proper training is available to identify worn crusher bits. Additionally, easy pull notches in crusher bits can provide quick and safe removal from the machine.

A T- Shank Crusher Bit

Summary

Overall, buying crusher bits for underground mining crushers requires careful consideration and research. By following these steps, you can ensure you buy the right cutting bits for your application and get the most out of your investment. For more information, visit the Kennametal catalog for Underground Mining.

Related Articles

- Shorten Product Development Cycles with Additive ManufacturingKennametal can produce more complex parts – faster. This is where the additive manufacturing process shines. Learn more with additive manufacturing expert Mike Orange.Kennametal can produce more complex parts – faster. This is where the additive manufacturing process shines. Learn more with additive manufacturing expert Mike Orange.

- How to Keep Your Tools RunningWear expert Blaise Nelson helps our customers in the construction industry to identify and apply the right Kennametal solutions for their job. Learn how our support and PCD tooling solutions in road milling set us apart.Wear expert Blaise Nelson helps our customers in the construction industry to identify and apply the right Kennametal solutions for their job. Learn how our support and PCD tooling solutions in road milling set us apart.

- How ROCTEC™ Outperforms Other Abrasive Waterjet NozzlesWear expert Carrie Bartkowiak has been with Kennametal for over 30 years. Carrie has been advancing the growth of ROCTEC and involved with all three launches of various ROCTEC materials.Wear expert Carrie Bartkowiak has been with Kennametal for over 30 years. Carrie has been advancing the growth of ROCTEC and involved with all three launches of various ROCTEC materials.

- Kennametal Trenching Bits Provide 2X the Tool Life of the CompetitionWhen a prospective trenching customer reached out about his equipment’s short tool life, the Kennametal team quickly identified a solution that reduced downtime and improved productivity.When a prospective trenching customer reached out about his equipment’s short tool life, the Kennametal team quickly identified a solution that reduced downtime and improved productivity.