Product Similar To:

Mill 1-10™ • Carbide Insert • EDPT-HD • Heavy Machining

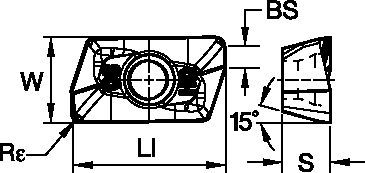

Shoulder milling insert with two cutting edges per insert

Material Number3642029

ISO Catalog IDEDPT10T312PDERHDANSI Catalog IDEP1012EHD

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3642029 |

| ISO Catalog ID | EDPT10T312PDERHD |

| ANSI Catalog ID | EP1012EHD |

| Grade | KC725M |

| [LI] Insert Length | 12.06 mm |

| [LI] Insert Length | .475 in |

| [S] Insert Thickness | 3.75 mm |

| [S] Insert Thickness | .148 in |

| [W] Insert Width | 6.74 mm |

| [W] Insert Width | .265 in |

| [BS] Corner Facet Length | 1.3 mm |

| [BS] Corner Facet Length | .051 in |

| [Rε] Corner Radius | 1.19 mm |

| [Rε] Corner Radius | .047 in |

| Average Chip Thickness [HM] | 0.082 mm |

| Average Chip Thickness [HM] | .0032 in |

| Cutting Edges per Insert | 2 |

Workpiece Materials

- Steel

- Stainless Steel

- High-Temp Alloys

Grades

KC725M

Coated carbide grade with an advanced PVD TiAlN coating. KC725M is a high-performance grade for milling steel, stainless steel, and high-temperature alloys. The good thermal shock resistance of the substrate makes this grade ideal for both wet and dry machining. Primarily for use in general and heavy machining.

Features and benefits

- Pressed-to-size, for lowest cost per cutting edge.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

Insert Selection Guide

| Material | Light | Medium | Heavy | |||

| P1–P2 | .E..LD | KCPM40 | .S..GD | KCPM40 | .E..HD | KCPM40 |

| P3–P4 | .E..LD | KCPK30 | .S..GD | KCPK30 | .E..HD | KCPK30 |

| P5–P6 | .E..LD | KC725M | .S..GD | KC725M | .E..HD | KC725M |

| M1–M2 | .E..LD | KCSM40 | .S..GD | KC725M | .E..HD | KCSM40 |

| M3 | .E..LD | KCSM40 | .S..GD | KCPM40 | .E..HD | KCSM40 |

| K1–K2 | .E..LD | KCK15 | .S..GD | KCK15 | .E..HD | KCK15 |

| K3 | .E..LD | KCK20B | .S..GD | KCK20B | .E..HD | KCK20B |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC422M | .E..LDJ | KC422M |

| N3 | .F..LDJ | KC410M | .E..LDJ | KC422M | .E..LDJ | KC422M |

| S1–S2 | .E..LD | KC725M | .S..GD | KC725M | .E..HD | KC725M |

| S3 | .E..LD | KCSM40 | .S..GE | KCSM40 | .E..HD | KCSM40 |

| S4 | .E..LD | KCSM40 | .S..GE | KCSM40 | .E..HD | KCSM40 |

| H1 | .E..LD | KC510M | – | – | – | – |

I have read and accepted the Terms & Conditions of use