KOR5™ DS • Radiused • 5 Flutes • 5 x D • Weldon® Shank • Inch

KOR5™ DS Solid Carbide End Mill for Dynamic Milling of Steel and Stainless Steel

제품 번호6764476

ISO 카탈로그 IDKOR5RA0250L125HBR030ANSI 카탈로그 IDKOR5RA0250L125HBR030

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Trochoidal Milling

램핑: 5°

사이드 밀링/숄더 밀링: 스퀘어 엔드

공구 치수: 플루트 구성: 5

섕크 — 원통형 웰던

헬릭스각: 40°

코너 스타일: 코너R

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 제품 번호 | 6764476 |

| ISO 카탈로그 ID | KOR5RA0250L125HBR030 |

| ANSI 카탈로그 ID | KOR5RA0250L125HBR030 |

| Grade | KC643M |

| Adapter Style Machine Side | Weldon |

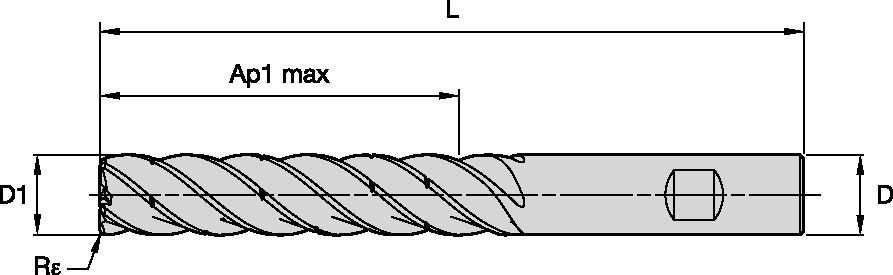

| [Re] Corner Radius | 0.75 mm |

| [Re] Corner Radius | 0.03 in |

| [Z] Number of Flutes | 5 |

| [D1] Effective Cutting Diameter | 6.35 mm |

| [D1] Effective Cutting Diameter | 0.25 in |

| [D] Adapter / Shank / Bore Diameter | 6.35 mm |

| [D] Adapter / Shank / Bore Diameter | 0.25 in |

| [AP1MAX] 1st Maximum Cutting Depth | 31.75 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.25 in |

| [L] Overall Length | 76.2 mm |

| [L] Overall Length | 3 in |

공작물 재료

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

사용 및 응용 분야

Trochoidal Milling

램핑: 5°

사이드 밀링/숄더 밀링: 스퀘어 엔드

공구 치수: 플루트 구성: 5

섕크 — 원통형 웰던

헬릭스각: 40°

코너 스타일: 코너R

재종

KC643M

PVD 다층(AlTiN)이 적용된 코팅 미립자 재종입니다. KC643M™은 스틸, 주철, 스테인리스강(습식) 및 티타늄(습식) 가공에 특히 적합한 매우 얇은 고경도 PVD 코팅입니다. 이 재종은 최대 52HRC 경도의 소재에 사용할 수 있습니다.

특징 및 장점

- Designed for trochoidal milling with low radial engagement and full length of cut.

- With chip deformers for ideal chip evacuation at high surface quality.

- Proprietary flute form reduces vibrations and improves tool life.

- Helix angle tailored to minimize vibration and optimize tool life.

- Front end geometry designed for maximum tool life in helical and ramping operations.

이송 및 속도를 계산하려면 솔루션을 생성하세요.

솔루션 생성 후 이송 및 속도 아이콘을 선택하면 추천 값이 제공됩니다. 기계와 사양을 추가하여 사용자 정보를 지정하거나 슬라이더를 사용하여 조정할 수 있습니다.

애플리케이션 데이터

KOR5™ DS • 5 Flutes • 5 x D • Application Data • Inch

| 소재 그룹 |  |  | |||||||||||

| 사이드 밀링(A) | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||||

| A | KC643M | D1 | |||||||||||

| 절삭속도 | frac. | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||

| ap | ae | 최소 | 최대 | dec. | .2500 | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 0 | 5 x D | 0.05 x D | 500 | – | 1770 | IPT | .0029 | .0044 | .0054 | .0063 | .0070 | .0078 |

| 1 | 5 x D | 0.05 x D | 500 | – | 1770 | IPT | .0029 | .0044 | .0054 | .0063 | .0070 | .0078 | |

| 2 | 5 x D | 0.05 x D | 460 | – | 1680 | IPT | .0029 | .0044 | .0054 | .0063 | .0070 | .0078 | |

| 3 | 5 x D | 0.05 x D | 400 | – | 1420 | IPT | .0024 | .0037 | .0046 | .0055 | .0062 | .0072 | |

| 4 | 5 x D | 0.05 x D | 300 | – | 1330 | IPT | .0022 | .0033 | .0041 | .0048 | .0054 | .0062 | |

| 5 | 5 x D | 0.05 x D | 200 | – | 890 | IPT | .0020 | .0029 | .0037 | .0044 | .0049 | .0058 | |

| 6 | 5 x D | 0.05 x D | 170 | – | 660 | IPT | .0017 | .0024 | .0031 | .0036 | .0040 | .0045 | |

| M | 1 | 5 x D | 0.05 x D | 300 | – | 1020 | IPT | .0024 | .0037 | .0046 | .0055 | .0062 | .0072 |

| 2 | 5 x D | 0.05 x D | 200 | – | 710 | IPT | .0020 | .0029 | .0037 | .0044 | .0049 | .0058 | |

| 3 | 5 x D | 0.05 x D | 200 | – | 620 | IPT | .0017 | .0024 | .0031 | .0036 | .0040 | .0045 | |

| K | 1 | 5 x D | 0.05 x D | 400 | – | 1330 | IPT | .0029 | .0044 | .0054 | .0063 | .0070 | .0078 |

| 2 | 5 x D | 0.05 x D | 370 | – | 1240 | IPT | .0024 | .0037 | .0046 | .0055 | .0062 | .0072 | |

| 3 | 5 x D | 0.05 x D | 370 | – | 1150 | IPT | .0020 | .0029 | .0037 | .0044 | .0049 | .0058 | |

| S | 1 | 5 x D | 0.05 x D | 170 | – | 800 | IPT | .0024 | .0037 | .0046 | .0055 | .0062 | .0072 |

| 2 | 5 x D | 0.05 x D | 80 | – | 710 | IPT | .0020 | .0029 | .0037 | .0044 | .0049 | .0058 | |

| 3 | 5 x D | 0.05 x D | 80 | – | 350 | IPT | .0013 | .0019 | .0025 | .0029 | .0033 | .0039 | |

| 4 | 5 x D | 0.05 x D | 170 | – | 530 | IPT | .0017 | .0027 | .0034 | .0040 | .0045 | .0053 | |

| H | 1 | 5 x D | 0.05 x D | 270 | – | 1240 | IPT | .0022 | .0033 | .0041 | .0048 | .0054 | .0062 |

| 2 | 5 x D | 0.05 x D | 230 | – | 1060 | IPT | .0017 | .0024 | .0031 | .0036 | .0040 | .0045 | |

TechnicalInfo

KOR5™ DS • 5 Flutes • 5 x D • Adjustment factor table for feed calculation • Inch

| Ae/D1 | 0.50% | 1.00% | 1.50% | 2.00% | 4.00% | 5.00% | |

| Speed factor | Kv | 2.00 | 1.97 | 1.93 | 1.38 | 1.03 | 1.00 |

| Feed factor | KFz | 1.27 | 1.18 | 1.14 | 1.09 | 1.05 | 1.00 |

I have read and accepted the Terms & Conditions of use