Fix-Perfect™ • Cast Iron • 0°

No matter how challenging your cast iron milling operation is, the Fix-Perfect high-performance face milling Program will boost your productivity and profitability. The 0° lead angle allows you to rough and finish in the same operation…greatly reducing machining steps and cost. The positive rake angle cutting geometry is designed to minimize workpiece breakout, requiring less horsepower. Inserts feature 8 cutting edges and are designed with adjustable insert seats.

- P Steel (17)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(17)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(17)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(17)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(17)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(17)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(17)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(17)

- M Stainless Steel (17)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(17)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(17)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(17)

- K Cast Iron (29)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(29)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(29)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(29)

- S High-Temp Alloys (15)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(12)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(12)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(12)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(15)

Face Milling (10)

Shoulder Milling (10)

Shoulder Square End (10)

- 2.0 in(2)

- 2.5 in(1)

- 3.0 in(2)

- 4.0 in(2)

- 5.0 in(2)

- 6.0 in(1)

- 50.801 mm(2)

- 63.5 mm(1)

- 76.2 mm(2)

- 101.601 mm(2)

- 127.0 mm(2)

- 152.4 mm(1)

- 6.0 mm(10)

- 0.237 in(10)

- 1.75 in(7)

- 2.375 in(3)

- 44.45 mm(7)

- 60.325 mm(3)

- 90.0 (10)

- A-Socket Head Cap Screw (10)

- 10 (1)

- 12 (2)

- 15 (1)

- 4 (1)

- 5 (2)

- 6 (1)

- 8 (2)

- 1.0 (20)

- 4.0 (13)

- 8.0 (22)

- 1.75 in(7)

- 2.375 in(3)

- 44.45 mm(7)

- 60.325 mm(3)

- 0.0 in(34)

- 0.031 in(1)

- 0.0 mm(34)

- 0.8 mm(1)

- 0.0 mm(1)

- 0.4 mm(24)

- 1.201 mm(17)

- 1.25 mm(13)

- 0.0 in(1)

- 0.016 in(24)

- 0.047 in(17)

- 0.049 in(13)

- KB1340 (10)

- KC520M (14)

- KC715M (10)

- KC725M (12)

- KC925M (10)

- KC930M (10)

- KCK15 (18)

- KCK20B (11)

- KCPK30 (13)

- KTPK20 (12)

- KY3500 (15)

- R (10)

- N (24)

- Y (1)

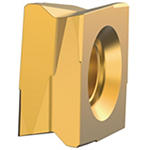

- FIX-PERFECT 8 CUT EDGES (24)

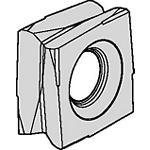

- FIX-PERFECT SQUARE (20)

- S-SQUARE 90 (11)

- FIX-PERFECT 8 CUT EDGES (14)

- FIX-PERFECT SQUARE (10)

- S-SQUARE 90 (1)

- 12.0 mm(25)

- 0.473 in(25)

- 6.5 mm(1)

- 6.575 mm(11)

- 11.0 mm(10)

- 11.076 mm(3)

- 0.256 in(1)

- 0.259 in(11)

- 0.433 in(10)

- 0.436 in(3)

- GN (7)

- GP (17)

- C N (5)

- H T (2)

- H W (18)

- H (25)

- SHELL MILL (10)

- 19.05 mm(3)

- 25.401 mm(2)

- 38.1 mm(4)

- 50.801 mm(1)

- 0.75 in(3)

- 1.0 in(2)

- 1.5 in(4)

- 2.0 in(1)