Product Similar To:

KNS® • Carbide Insert • XCP-SGP • Single Ended

Slot milling insert for flat-bottom machining in multiple materials.

Material Number5615026

ISO Catalog IDXCP16S220F015SGPANSI Catalog IDXCP16S220F015SGP

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5615026 |

| ISO Catalog ID | XCP16S220F015SGP |

| ANSI Catalog ID | XCP16S220F015SGP |

| Grade | KCPK30 |

| Insert Size | 16 |

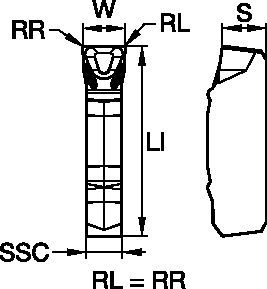

| [W] Cutting Width | 2.21 mm |

| [W] Cutting Width | .087 in |

| [LI] Insert Length | 11 mm |

| [LI] Insert Length | .433 in |

| [RR] Corner Radius | 0.15 mm |

| [RR] Corner Radius | .006 in |

| [RL] Corner Radius | 0.15 mm |

| [RL] Corner Radius | .006 in |

| [S] Insert Thickness | 2.78 mm |

| [S] Insert Thickness | .109 in |

| Average Chip Thickness [HM] | 0.04 mm |

| Average Chip Thickness [HM] | .0016 in |

| Cutting Edges per Insert | 1 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

Grades

KCPK30

Coated carbide grade with CVD multilayer (TiN/TiCN/Al2O3) and advanced Beyond™ post-coat treatment. Substrate is very tough. KCPK30 has a wide application area in general and roughing milling of steels and cast irons. Performs best dry, but can also be used wet.

Features and benefits

- From light to heavy machining, the positive SGP chipbreaker geometry ensures smooth cutting action, and efficient chip evacuation.

- The Double-V Design of the insert and the insert pocket securely holds the insert in place, minimises radial runout, providing high slot width accuracy and high repeatability.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

| KNS® Slotting Cutter • Insert Selection Guide | ||||||

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | (Strong geometry) | ||||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1-P2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P3-P4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P5-P6 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| M1-M2 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| M3 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| K1-K2 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| K3 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| N1-N2 | – | – | .S..GP | KCU25 | – | – |

| N3 | – | – | .S..GP | KCU25 | – | – |

| S1-S2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S3 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use