Produkt ähnlich wie:

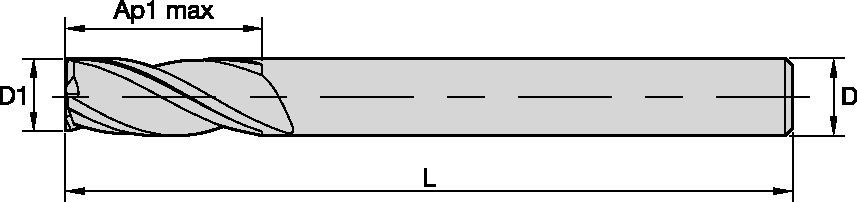

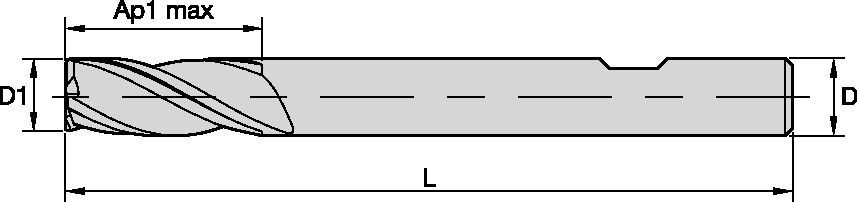

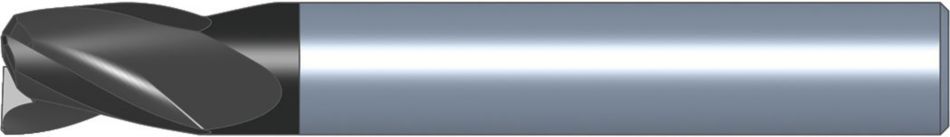

GOmill™ GP • Square End • 3 Flutes • Plain Shank • Inch

General Purpose Solid Carbide End Mill

Material Nummer6143947

ISO Katalog Nummer3SE0188IX100AANSI Katalog Nummer3SE0188IX100A

- P Stahl

- M Rostfreier Stahl

- K Gusseisen

Tauchfräsen

Schräg-Eintauchfräsen Ins Volle

Nutenfräsen: Ebene Stirnfläche

Umfangfräsen/Schulterfräsen: Ebene Stirnfläche

Werkzeugabmessungen: Schneidreihen: 3

Spiralwinkel: 30°

Schneideckenausführung: Ebene Stirnfläche

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 6143947 |

| ISO Katalog Nummer | 3SE0188IX100A |

| ANSI Katalog Nummer | 3SE0188IX100A |

| Sorte | KC633M |

| Aufnahmeart Maschinenseite | Straight-Cylindrical |

| [Z] Anzahl der Spannuten | 3 |

| [D1] Effektiver Schneidendurchmesser | 4.763 mm |

| [D1] Effektiver Schneidendurchmesser | 0.1875 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 4.763 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 0.1875 in |

| [AP1MAX] 1. maximale Schnitttiefe | 25.4 mm |

| [AP1MAX] 1. maximale Schnitttiefe | 1 in |

| [L] Gesamtlänge | 101.6 mm |

| [L] Gesamtlänge | 4 in |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Gusseisen

Uses and application

Tauchfräsen

Schräg-Eintauchfräsen Ins Volle

Nutenfräsen: Ebene Stirnfläche

Umfangfräsen/Schulterfräsen: Ebene Stirnfläche

Werkzeugabmessungen: Schneidreihen: 3

Spiralwinkel: 30°

Schneideckenausführung: Ebene Stirnfläche

Grades

KC633M

Hartmetallsorte mit PVD-Mehrlagenbeschichtung. KC633M™ ist zum Trockenfräsen der meisten Werkstoffe, mit Ausnahme gehärteter Werkstoffe, konzipiert. Diese Sorte zeichnet sich besonders durch hohe Härte und Verschleißfestigkeit aus. Sie bietet herausragenden Schutz gegen Kolk- und Freiflächenverschleiß bei Vollhartmetall-Werkzeugen.

Features and benefits

- Solid carbide end mill with excellent cost-benefit ratio

- Eccentric relief increases cutting edge stability for long tool life and high surface quality

- Eccentric relief eases regrinding and reduces reconditioning cost

- Center cutting for plunging and ramping operations

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Toleranz

| Toleranzen für Schaftfräser | |||

| D1 | Toleranz | D | Toleranz h6 + / - |

| Alle | +.000/- .002" | ≤1/8" | +0/-.00024" |

| +0/-.00031" | |||

| +0/-.00035" | |||

| +0/-.00043" | |||

| +0/-.00051" | |||

Anwendungsdaten

GOmill • 3SE..IS-IR • 3 Flute • Short • Regular

| Werkstoffgruppe |  |  |  | ||||||||||||||||||

| Eckfräsen (A) und Nutfräsen (B) | KC633M | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | |||||||||||||||||||

| A | B | Schnittgeschwindigkeit | D1 | ||||||||||||||||||

| frac. | 1/32 | 1/16 | 5/64 | 3/32 | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||||

| ap | ae | ap | Min. | Max. | dec. | .0313 | .0625 | .0781 | .0938 | .1250 | .1875 | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 0 | 2.0 x D | 0.1 x D | 0.5 x D | 490 | – | 660 | IPT | .0002 | .0005 | .0006 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 |

| 1 | 2.0 x D | 0.1 x D | 0.5 x D | 490 | – | 660 | IPT | .0002 | .0005 | .0006 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 | |

| 2 | 2.0 x D | 0.1 x D | 0.5 x D | 460 | – | 620 | IPT | .0002 | .0005 | .0006 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 | |

| 3 | 2.0 x D | 0.1 x D | 0.5 x D | 390 | – | 520 | IPT | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 4 | 2.0 x D | 0.1 x D | 0.5 x D | 300 | – | 490 | IPT | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0014 | .0017 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| M | 1 | 2.0 x D | 0.1 x D | 0.5 x D | 300 | – | 380 | IPT | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | 2.0 x D | 0.1 x D | 0.5 x D | 200 | – | 260 | IPT | .0002 | .0003 | .0004 | .0005 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| K | 1 | 2.0 x D | 0.1 x D | 0.5 x D | 390 | – | 490 | IPT | .0002 | .0005 | .0006 | .0007 | .0009 | .0014 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 |

| 2 | 2.0 x D | 0.1 x D | 0.5 x D | 360 | – | 460 | IPT | .0002 | .0004 | .0004 | .0005 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| N | 1 | 2.0 x D | 0.1 x D | 0.5 x D | 820 | – | 3250 | IPT | .0003 | .0007 | .0008 | .0010 | .0013 | .0019 | .0025 | .0031 | .0038 | .0050 | .0063 | .0075 | .0100 |

| 2 | 2.0 x D | 0.1 x D | 0.5 x D | 820 | – | 3250 | IPT | .0003 | .0005 | .0006 | .0008 | .0010 | .0015 | .0020 | .0025 | .0030 | .0040 | .0050 | .0060 | .0080 | |

| 4 | 2.0 x D | 0.1 x D | 0.5 x D | 820 | – | 3250 | IPT | .0003 | .0006 | .0007 | .0008 | .0011 | .0017 | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 | |

| Werkstoffgruppe |  |  | ||||||||||||||

| Schulterfräsen (A) | KC633M | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||||||

| A | Schnittgeschwindigkeit | D1 | ||||||||||||||

| frac. | 1/8 | 5/32 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| ap | ae | Min. | Max. | dec. | .1250 | .1563 | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 0 | 2.0 x D | 0.1 x D | 490 | – | 660 | IPT | .0009 | .0011 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 |

| 1 | 2.0 x D | 0.1 x D | 490 | – | 660 | IPT | .0009 | .0011 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 | |

| 2 | 2.0 x D | 0.1 x D | 460 | – | 620 | IPT | .0009 | .0011 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 | |

| 3 | 2.0 x D | 0.1 x D | 390 | – | 520 | IPT | .0007 | .0009 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 4 | 2.0 x D | 0.1 x D | 300 | – | 490 | IPT | .0007 | .0008 | .0014 | .0017 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| M | 1 | 2.0 x D | 0.1 x D | 300 | – | 380 | IPT | .0007 | .0009 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | 2.0 x D | 0.1 x D | 200 | – | 260 | IPT | .0006 | .0007 | .0012 | .0016 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| K | 1 | 2.0 x D | 0.1 x D | 390 | – | 490 | IPT | .0009 | .0011 | .0018 | .0023 | .0027 | .0034 | .0039 | .0044 | .0049 |

| 2 | 2.0 x D | 0.1 x D | 360 | – | 460 | IPT | .0007 | .0009 | .0015 | .0020 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| N | 1 | 2.0 x D | 0.1 x D | 820 | – | 3250 | IPT | .0013 | .0016 | .0025 | .0031 | .0038 | .0050 | .0063 | .0075 | .0100 |

| 2 | 2.0 x D | 0.1 x D | 820 | – | 2450 | IPT | .0010 | .0013 | .0020 | .0025 | .0030 | .0040 | .0050 | .0060 | .0080 | |

| 4 | 2.0 x D | 0.1 x D | 820 | – | 2450 | IPT | .0011 | .0014 | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use