Produkt ähnlich wie:

Kenna Universal™ • B976 • 3 x D • Interne Kühlmittelversorgung • Zylinderschaft

Vollhartmetall-Stufenbohrer für universelle Anwendungen

Material Nummer1913522

ISO Katalog NummerB976A05700ANSI Katalog NummerB976A05700

- P Stahl

- M Rostfreier Stahl

- K Gusseisen

- N NE-Metalle

- S Hochwarmfeste Legierungen

Drilling: Stacked Plates

Bohren

Bohren: Schräge Austrittsfläche

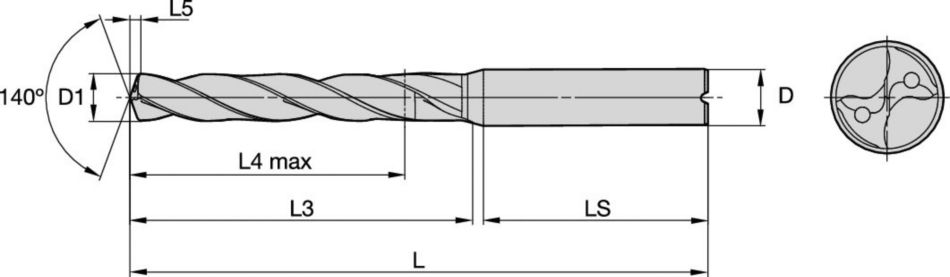

Werkzeugabmessungen: 2 Schneidreihen/4 Führungsfasen/innere Kühlmittelzuführung

DIN 6535

DIN 6537

Drilling - Through Coolant

Innere Kühlmittelzuführung: MQL (Minimalmengenschmierung): Bohren

Zylinderschaft – ohne Spannfläche ≤h6

Spiralwinkel: 30°

Drilling: Cross-Hole Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Nummer | 1913522 |

| ISO Katalog Nummer | B976A05700 |

| ANSI Katalog Nummer | B976A05700 |

| Sorte | KCU15 |

| [D1] Bohrerdurchmesser M | 5.7 mm |

| [D1] Bohrerdurchmesser M | .2244 in |

| [L] Gesamtlänge | 66 mm |

| [L] Gesamtlänge | 2.598 in |

| [L3] Spannuten-Länge | 28 mm |

| [L3] Spannuten-Länge | 1.102 in |

| [L4] Maximale Bohrtiefe | 20 mm |

| [L4] Maximale Bohrtiefe | .7874 in |

| [L5] Bohrerspitzenlänge | 0.952 mm |

| [L5] Bohrerspitzenlänge | .0375 in |

| [LS] Schaftlänge | 36 mm |

| [LS] Schaftlänge | 1.417 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 6 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | .2362 in |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Gusseisen

- NE-Metalle

- Hochwarmfeste Legierungen

Uses and application

Drilling: Stacked Plates

Bohren

Bohren: Schräge Austrittsfläche

Werkzeugabmessungen: 2 Schneidreihen/4 Führungsfasen/innere Kühlmittelzuführung

DIN 6535

DIN 6537

Drilling - Through Coolant

Innere Kühlmittelzuführung: MQL (Minimalmengenschmierung): Bohren

Zylinderschaft – ohne Spannfläche ≤h6

Spiralwinkel: 30°

Drilling: Cross-Hole Drilling

Features and benefits

- Four-margin land design provides hole straightness and roundness, even when drilling cross-holes

- Low thrust drill point design offers excellent centering and is ideal for unstable machining conditions

- Easy to recondition, delivering extended tool life

- Versatile across various machines

- All shanks meet DIN 6535 and 69090-03 requirements for Minimum Quantity Lubrication (MQL)

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Toleranz

| Toleranz • Zoll | ||

| Nennmaßbereich | D1 Toleranz m7 | D Toleranz h6 |

| .0002/.0006 | .0000/-.0003 | |

| .0002/.0008 | .0000/-.0004 | |

| .0003/.0010 | .0000/-.0004 | |

| .0003/.0011 | .0000/-.0005 | |

| Toleranz • metrisch | ||

| Nennmaßbereich | D1 Toleranz m7 | D Toleranz h6 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 | |

Dimension

Abmessungen von Kennametal Vollhartmetall-Bohrer (Baureihe B*)

| mm | KURZ* | LANG* | EXTRA LANG** | |||||||||

| Ø | DIN 6535 | ~3 x D | ~5 x D | ~8 x D | ||||||||

| D1 min | D1 max | D | LS min | L | L3 | L4 | L | L3 | L4 | L | L3 | L4 |

| 1,000 | 1,400 | 4 | 28 | 58 | 7 | 5 | 58 | 9 | 6 | 58 | 12 | 10 |

| 1,401 | 1,900 | 4 | 28 | 58 | 9 | 6 | 58 | 12 | 9 | 58 | 18 | 15 |

| 1,901 | 2,300 | 4 | 28 | 58 | 13 | 9 | 58 | 18 | 14 | 66 | 26 | 22 |

| 2,301 | 2,990 | 4 | 28 | 58 | 17 | 12 | 58 | 22 | 17 | 66 | 30 | 25 |

| 3,000 | 3,750 | 6 | 36 | 62 | 20 | 14 | 66 | 28 | 23 | 78 | 40 | 33 |

| 3,751 | 4,750 | 6 | 36 | 66 | 24 | 17 | 74 | 36 | 29 | 87 | 49 | 41 |

| 4,751 | 6,000 | 6 | 36 | 66 | 28 | 20 | 82 | 44 | 35 | 94 | 56 | 48 |

| 6,001 | 7,000 | 8 | 36 | 79 | 34 | 24 | 91 | 53 | 43 | 105 | 67 | 57 |

| 7,001 | 8,000 | 8 | 36 | 79 | 41 | 29 | 91 | 53 | 43 | 110 | 72 | 61 |

| 8,001 | 10,000 | 10 | 40 | 89 | 47 | 35 | 103 | 61 | 49 | 122 | 80 | 68 |

| 10,001 | 12,000 | 12 | 45 | 102 | 55 | 40 | 118 | 71 | 56 | 141 | 94 | 79 |

| 12,001 | 14,000 | 14 | 45 | 107 | 60 | 43 | 124 | 77 | 60 | 155 | 108 | 91 |

| 14,001 | 16,000 | 16 | 48 | 115 | 65 | 45 | 133 | 83 | 63 | 171 | 121 | 101 |

| 16,001 | 18,000 | 18 | 48 | 123 | 73 | 51 | 143 | 93 | 71 | 185 | 135 | 113 |

| 18,001 | 20,000 | 20 | 50 | 131 | 79 | 55 | 153 | 101 | 77 | 200 | 148 | 124 |

| 20,001 | 22,000 | 20 | 50 | 141 | 86 | 60 | 167 | 112 | 85 | 217 | 162 | 136 |

| 22,001 | 25,000 | 25 | 56 | 153 | 95 | 65 | 184 | 126 | 98 | 238 | 180 | 150 |

| * D1 20 mm gemäß DIN 6537K | ||||||||||||

| * D1 | ||||||||||||

| ** gemäß Werksnorm | ||||||||||||

Anwendungsdaten

| Werkstoffgruppe | Schnittgeschwindigkeit | Zoll | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | ||||||||||||

| .009-.017 | .011-.021 | |||||||||||||

| 300 | 430 | |||||||||||||

| 390 | 490 | |||||||||||||

| 230 | 300 | 360 | ||||||||||||

| 70 | .001-.003 | .001-.003 | .002-.004 | .004-.006 | .005-.007 | .006-.008 | ||||||||

| 100 | .001-.003 | .001-.003 | .002-.004 | .002-.004 | .003-.005 | .004-.006 | .004-.006 | .005-.007 | .006-.008 | |||||

| 50 | 110 | .001-.003 | .001-.003 | .002-.004 | .002-.004 | .003-.005 | .004-.006 | .004-.006 | .005-.007 | .006-.008 | ||||

| 70 | 100 | .001-.002 | .002-.004 | .002-.004 | .003-.005 | .003-.005 | ||||||||

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | ||||||||||||

| 0,04–0,10 | 0,06–0,12 | 0,07–0,14 | 0,09–0,19 | 0,11–0,22 | 0,13–0,26 | 0,15–0,30 | 0,19–0,36 | 0,24–0,46 | ||||||

| 0,05–0,12 | 0,07–0,14 | 0,08–0,16 | 0,11–0,22 | 0,13–0,26 | 0,15–0,31 | 0,18–0,35 | 0,22–0,42 | 0,28–0,54 | ||||||

| 0,05–0,12 | 0,07–0,14 | 0,08–0,16 | 0,12–0,22 | 0,14–0,26 | 0,17–0,31 | 0,20–0,35 | 0,24–0,42 | 0,31–0,53 | ||||||

| 0,06–0,13 | 0,08–0,15 | 0,09–0,17 | 0,13–0,23 | 0,15–0,28 | 0,19–0,33 | 0,22–0,38 | 0,26–0,47 | 0,34–0,59 | ||||||

| 0,06–0,13 | 0,07–0,15 | 0,08–0,17 | 0,12–0,23 | 0,14–0,28 | 0,17–0,33 | 0,19–0,38 | 0,23–0,47 | 0,29–0,59 | ||||||

| 0,06–0,12 | 0,08–0,13 | 0,10–0,15 | 0,12–0,19 | 0,16–0,24 | 0,20–0,27 | 0,24–0,30 | 0,28–0,38 | 0,32–0,44 | ||||||

| 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,14 | 0,10–0,18 | 0,13–0,22 | 0,14–0,24 | 0,18–0,32 | 0,23–0,41 | ||||||

| 0,03–0,06 | 0,04–0,07 | 0,05–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 | ||||||

| 0,03–0,07 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,09–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | ||||||

| 0,03–0,06 | 0,04–0,07 | 0,05–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 | ||||||

| 90 | 130 | 0,09–0,17 | 0,11–0,22 | 0,12–0,24 | 0,16–0,31 | 0,20–0,38 | 0,23–0,44 | 0,25–0,49 | 0,31–0,60 | 0,38–0,74 | ||||

| 120 | 150 | 0,11–0,15 | 0,12–0,16 | 0,13–0,19 | 0,16–0,25 | 0,20–0,31 | 0,23–0,36 | 0,25–0,40 | 0,31–0,48 | 0,38–0,60 | ||||

| 70 | 90 | 110 | 0,07–0,15 | 0,08–0,17 | 0,09–0,19 | 0,12–0,25 | 0,14–0,30 | 0,17–0,35 | 0,19–0,40 | 0,24–0,48 | 0,30–0,60 | |||

| 0,06–0,13 | 0,08–0,14 | 0,10–0,16 | 0,12–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 | ||||||

| 0,06–0,12 | 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,44 | 0,32–0,52 | ||||||

| 0,11–0,14 | 0,12–0,14 | 0,13–0,16 | 0,14–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,44 | ||||||

| 0,06–0,12 | 0,08–0,16 | 0,01–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,48 | ||||||

| 20 | 0,02–0,07 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |||||

| 30 | 0,02–0,07 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |||||

| 15 | 35 | 0,02–0,07 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | ||||

| 20 | 30 | 0,02–0,04 | 0,03–0,05 | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,05–0,11 | 0,07–0,12 | 0,08–0,13 | 0,09–0,14 | ||||

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | 2,0 | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| P | 0 | 80 | 120 | 160 | mm/r | 0,04–0,10 | 0,06–0,12 | 0,07–0,14 | 0,09–0,19 | 0,11–0,22 | 0,13–0,26 | 0,15–0,30 | 0,19–0,36 | 0,24–0,46 |

| 1 | 70 | 100 | 140 | mm/r | 0,05–0,12 | 0,07–0,14 | 0,08–0,16 | 0,11–0,22 | 0,13–0,26 | 0,15–0,31 | 0,18–0,35 | 0,22–0,42 | 0,28–0,54 | |

| 2 | 90 | 120 | 140 | mm/r | 0,05–0,12 | 0,07–0,14 | 0,08–0,16 | 0,12–0,22 | 0,14–0,26 | 0,17–0,31 | 0,20–0,35 | 0,24–0,42 | 0,31–0,53 | |

| 3 | 60 | 80 | 100 | mm/r | 0,06–0,13 | 0,08–0,15 | 0,09–0,17 | 0,13–0,23 | 0,15–0,28 | 0,19–0,33 | 0,22–0,38 | 0,26–0,47 | 0,34–0,59 | |

| 4 | 50 | 80 | 100 | mm/r | 0,06–0,13 | 0,07–0,15 | 0,08–0,17 | 0,12–0,23 | 0,14–0,28 | 0,17–0,33 | 0,19–0,38 | 0,23–0,47 | 0,29–0,59 | |

| 5 | 50 | 60 | 80 | mm/r | 0,06–0,12 | 0,08–0,13 | 0,10–0,15 | 0,12–0,19 | 0,16–0,24 | 0,20–0,27 | 0,24–0,30 | 0,28–0,38 | 0,32–0,44 | |

| 6 | 40 | 50 | 70 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,14 | 0,10–0,18 | 0,13–0,22 | 0,14–0,24 | 0,18–0,32 | 0,23–0,41 | |

| M | 1 | 30 | 40 | 50 | mm/r | 0,03–0,06 | 0,04–0,07 | 0,05–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 |

| 2 | 40 | 50 | 60 | mm/r | 0,03–0,07 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,09–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | |

| 3 | 30 | 40 | 50 | mm/r | 0,03–0,06 | 0,04–0,07 | 0,05–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 | |

| K | 1 | 90 | 130 | 170 | mm/r | 0,09–0,17 | 0,11–0,22 | 0,12–0,24 | 0,16–0,31 | 0,20–0,38 | 0,23–0,44 | 0,25–0,49 | 0,31–0,60 | 0,38–0,74 |

| 2 | 80 | 120 | 150 | mm/r | 0,11–0,15 | 0,12–0,16 | 0,13–0,19 | 0,16–0,25 | 0,20–0,31 | 0,23–0,36 | 0,25–0,40 | 0,31–0,48 | 0,38–0,60 | |

| 3 | 70 | 90 | 110 | mm/r | 0,07–0,15 | 0,08–0,17 | 0,09–0,19 | 0,12–0,25 | 0,14–0,30 | 0,17–0,35 | 0,19–0,40 | 0,24–0,48 | 0,30–0,60 | |

| N | 1 | 90 | 230 | 315 | mm/r | 0,06–0,13 | 0,08–0,14 | 0,10–0,16 | 0,12–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 |

| 2 | 90 | 225 | 270 | mm/r | 0,06–0,12 | 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,44 | 0,32–0,52 | |

| 3 | 90 | 180 | 270 | mm/r | 0,11–0,14 | 0,12–0,14 | 0,13–0,16 | 0,14–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,44 | |

| 4 | 90 | 135 | 180 | mm/r | 0,06–0,12 | 0,08–0,16 | 0,01–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,48 | |

| S | 1 | 10 | 20 | 30 | mm/r | 0,02–0,07 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 |

| 2 | 10 | 20 | 30 | mm/r | 0,02–0,07 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |

| 3 | 15 | 25 | 35 | mm/r | 0,02–0,07 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |

| 4 | 20 | 30 | 40 | mm/r | 0,02–0,04 | 0,03–0,05 | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,05–0,11 | 0,07–0,12 | 0,08–0,13 | 0,09–0,14 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | |||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||||

| Min. | Startwert | Max. | |||||||||||

| 0,05–0,11 | 0,08–0,14 | 0,09–0,19 | 0,11–0,22 | 0,13–0,26 | 0,15–0,30 | 0,19–0,36 | 0,24–0,46 | ||||||

| 0,06–0,13 | 0,09–0,16 | 0,11–0,22 | 0,13–0,26 | 0,15–0,31 | 0,18–0,35 | 0,22–0,42 | 0,28–0,54 | ||||||

| 0,06–0,13 | 0,08–0,16 | 0,12–0,22 | 0,14–0,26 | 0,17–0,31 | 0,20–0,35 | 0,24–0,42 | 0,31–0,53 | ||||||

| 0,07–0,15 | 0,09–0,17 | 0,13–0,23 | 0,15–0,28 | 0,19–0,33 | 0,22–0,38 | 0,26–0,47 | 0,34–0,59 | ||||||

| 0,06–0,15 | 0,08–0,17 | 0,12–0,23 | 0,14–0,28 | 0,17–0,33 | 0,19–0,38 | 0,23–0,47 | 0,29–0,59 | ||||||

| 0,06–0,12 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,16–0,26 | 0,18–0,28 | 0,22–0,36 | 0,26–0,42 | ||||||

| 0,05–0,07 | 0,06–0,10 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,14–0,24 | 0,18–0,32 | 0,23–0,41 | ||||||

| 0,04–0,07 | 0,05–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 | ||||||

| 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,09–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | ||||||

| 0,04–0,07 | 0,06–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 | ||||||

| 120 | 160 | 0,11–0,22 | 0,12–0,24 | 0,16–0,31 | 0,20–0,38 | 0,23–0,44 | 0,25–0,49 | 0,31–0,60 | 0,38–0,74 | ||||

| 80 | 100 | 130 | 0,10–0,17 | 0,12–0,19 | 0,16–0,25 | 0,20–0,31 | 0,23–0,36 | 0,25–0,40 | 0,31–0,48 | 0,38–0,60 | |||

| 70 | 80 | 100 | 0,07–0,15 | 0,09–0,19 | 0,12–0,25 | 0,14–0,30 | 0,17–0,35 | 0,19–0,40 | 0,25–0,48 | 0,30–0,60 | |||

| 0,08–0,14 | 0,10–0,16 | 0,12–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 | ||||||

| 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,44 | 0,32–0,52 | ||||||

| 0,12–0,14 | 0,13–0,16 | 0,14–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,44 | ||||||

| 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,48 | ||||||

| 10 | 20 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | ||||

| 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | ||||||

| 15 | 35 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | ||||

| 30 | 40 | 0,03–0,05 | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,05–0,11 | 0,07–0,12 | 0,08–0,13 | 0,09–0,14 | ||||

| Werkstoffgruppe | Schnittgeschwindigkeit | Zoll | |||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||||

| Min. | Startwert | Max. | |||||||||||

| .002–.004 | .003–.005 | .004–.007 | .004–.009 | .005–.010 | .006–.012 | .007–.014 | .009–.018 | ||||||

| .002–.005 | .004–.006 | .004–.009 | .005–.010 | .006–.012 | .007–.014 | .009–.017 | .011–.021 | ||||||

| .002–.005 | .003–.006 | .005–.009 | .006–.010 | .007–.012 | .008–.014 | .009–.017 | .012–.021 | ||||||

| .003–.006 | .004–.007 | .005–.009 | .006–.011 | .008–.013 | .009–.015 | .010–.019 | .013–.023 | ||||||

| .002–.006 | .003–.007 | .005–.009 | .006–.011 | .007–.013 | .008–.015 | .009–.019 | .011–.023 | ||||||

| .002–.005 | .003–.006 | .004–.007 | .005–.009 | .006–.010 | .007–.011 | .009–.014 | .010–.017 | ||||||

| .002–.003 | .002–.004 | .003–.006 | .004–.007 | .005–.009 | .006–.009 | .007–.013 | .009–.016 | ||||||

| .002–.003 | .002–.004 | .003–.004 | .004–.005 | .004–.006 | .005–.006 | .006–.007 | .006–.008 | ||||||

| .002–.003 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | ||||||

| .002–.003 | .002–.004 | .003–.004 | .004–.005 | .004–.006 | .005–.006 | .006–.007 | .006–.008 | ||||||

| 390 | 520 | .004–.009 | .005–.009 | .006–.012 | .008–.015 | .009–.017 | .010–.019 | .012–.024 | .015–.029 | ||||

| 260 | 330 | 430 | .004–.007 | .005–.008 | .006–.010 | .008–.012 | .009–.014 | .010–.016 | .012–.019 | .015–.024 | |||

| 230 | 260 | 330 | .003–.006 | .004–.008 | .005–.010 | .006–.012 | .007–.014 | .008–.016 | .010–.019 | .012–.024 | |||

| .003–.006 | .004–.006 | .005–.008 | .006–.009 | .008–.011 | .009–.013 | .011–.016 | .013–.019 | ||||||

| .003–.006 | .004–.008 | .005–.009 | .006–.011 | .008–.013 | .009–.014 | .011–.017 | .013–.021 | ||||||

| .005–.006 | .005–.006 | .006–.008 | .006–.009 | .008–.011 | .009–.013 | .011–.016 | .013–.017 | ||||||

| .003–.006 | .004–.008 | .005–.009 | .006–.011 | .008–.013 | .009–.014 | .011–.016 | .013–.019 | ||||||

| 30 | 70 | .001–.003 | .002–.004 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .005–.007 | .006–.008 | ||||

| .001–.003 | .002–.004 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .005–.007 | .006–.008 | ||||||

| 50 | 110 | .001–.003 | .002–.004 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .005–.007 | .006–.008 | ||||

| 100 | 130 | .001–.002 | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.005 | .003–.005 | .004–.006 | ||||

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | |||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||||

| Min. | Startwert | Max. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| P | 0 | 70 | 90 | 115 | mm/r | 0,05–0,11 | 0,08–0,14 | 0,09–0,19 | 0,11–0,22 | 0,13–0,26 | 0,15–0,30 | 0,19–0,36 | 0,24–0,46 |

| 1 | 60 | 70 | 100 | mm/r | 0,06–0,13 | 0,09–0,16 | 0,11–0,22 | 0,13–0,26 | 0,15–0,31 | 0,18–0,35 | 0,22–0,42 | 0,28–0,54 | |

| 2 | 80 | 90 | 100 | mm/r | 0,06–0,13 | 0,08–0,16 | 0,12–0,22 | 0,14–0,26 | 0,17–0,31 | 0,20–0,35 | 0,24–0,42 | 0,31–0,53 | |

| 3 | 50 | 70 | 90 | mm/r | 0,07–0,15 | 0,09–0,17 | 0,13–0,23 | 0,15–0,28 | 0,19–0,33 | 0,22–0,38 | 0,26–0,47 | 0,34–0,59 | |

| 4 | 50 | 70 | 100 | mm/r | 0,06–0,15 | 0,08–0,17 | 0,12–0,23 | 0,14–0,28 | 0,17–0,33 | 0,19–0,38 | 0,23–0,47 | 0,29–0,59 | |

| 5 | 40 | 50 | 70 | mm/r | 0,06–0,12 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,16–0,26 | 0,18–0,28 | 0,22–0,36 | 0,26–0,42 | |

| 6 | 30 | 40 | 60 | mm/r | 0,05–0,07 | 0,06–0,10 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,14–0,24 | 0,18–0,32 | 0,23–0,41 | |

| M | 1 | 30 | 40 | 50 | mm/r | 0,04–0,07 | 0,05–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 |

| 2 | 40 | 50 | 60 | mm/r | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,09–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | |

| 3 | 30 | 40 | 50 | mm/r | 0,04–0,07 | 0,06–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 | |

| K | 1 | 80 | 120 | 160 | mm/r | 0,11–0,22 | 0,12–0,24 | 0,16–0,31 | 0,20–0,38 | 0,23–0,44 | 0,25–0,49 | 0,31–0,60 | 0,38–0,74 |

| 2 | 80 | 100 | 130 | mm/r | 0,10–0,17 | 0,12–0,19 | 0,16–0,25 | 0,20–0,31 | 0,23–0,36 | 0,25–0,40 | 0,31–0,48 | 0,38–0,60 | |

| 3 | 70 | 80 | 100 | mm/r | 0,07–0,15 | 0,09–0,19 | 0,12–0,25 | 0,14–0,30 | 0,17–0,35 | 0,19–0,40 | 0,25–0,48 | 0,30–0,60 | |

| N | 1 | 90 | 230 | 270 | mm/r | 0,08–0,14 | 0,10–0,16 | 0,12–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 |

| 2 | 90 | 220 | 270 | mm/r | 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,44 | 0,32–0,52 | |

| 3 | 90 | 180 | 225 | mm/r | 0,12–0,14 | 0,13–0,16 | 0,14–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,44 | |

| 4 | 90 | 130 | 270 | mm/r | 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,48 | |

| S | 1 | 10 | 20 | 30 | mm/r | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 |

| 2 | 10 | 20 | 30 | mm/r | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |

| 3 | 15 | 25 | 35 | mm/r | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |

| 4 | 20 | 30 | 40 | mm/r | 0,03–0,05 | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,05–0,11 | 0,07–0,12 | 0,08–0,13 | 0,09–0,14 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | |||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||||

| Min. | Startwert | Max. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| P | 0 | 80 | 110 | 140 | mm/U | 0,06–0,12 | 0,07–0,14 | 0,09–0,19 | 0,11–0,22 | 0,13–0,26 | 0,15–0,30 | 0,15–0,30 | 0,24–0,46 |

| 1 | 70 | 100 | 130 | mm/U | 0,07–0,14 | 0,08–0,16 | 0,11–0,22 | 0,13–0,26 | 0,15–0,31 | 0,18–0,35 | 0,18–0,35 | 0,28–0,54 | |

| 2 | 70 | 100 | 110 | mm/U | 0,07–0,14 | 0,08–0,16 | 0,12–0,22 | 0,14–0,26 | 0,17–0,31 | 0,20–0,35 | 0,20–0,35 | 0,31–0,53 | |

| 3 | 60 | 80 | 100 | mm/U | 0,08–0,15 | 0,09–0,17 | 0,13–0,23 | 0,15–0,28 | 0,19–0,33 | 0,22–0,38 | 0,22–0,38 | 0,34–0,59 | |

| 4 | 50 | 60 | 70 | mm/U | 0,07–0,14 | 0,08–0,17 | 0,12–0,23 | 0,14–0,28 | 0,17–0,33 | 0,19–0,38 | 0,19–0,38 | 0,29–0,59 | |

| 5 | 50 | 60 | 70 | mm/U | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,14–0,24 | 0,16–0,26 | |

| 6 | 40 | 50 | 60 | mm/U | 0,03–0,08 | 0,04–0,10 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,14–0,24 | 0,16–0,26 | |

| M | 1 | 30 | 40 | 50 | mm/U | 0,04–0,07 | 0,05–0,09 | 0,07–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 |

| 2 | 40 | 50 | 60 | mm/U | 0,04–0,07 | 0,06–0,10 | 0,07–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 | |

| 3 | 30 | 40 | 50 | mm/U | 0,03–0,07 | 0,05–0,09 | 0,06–0,11 | 0,08–0,12 | 0,09–0,13 | 0,11–0,15 | 0,13–0,17 | 0,15–0,19 | |

| K | 1 | 80 | 120 | 160 | mm/U | 0,10–0,15 | 0,12–0,20 | 0,16–0,28 | 0,20–0,34 | 0,23–0,40 | 0,25–0,44 | 0,31–0,54 | 0,38–0,68 |

| 2 | 70 | 110 | 140 | mm/U | 0,10–0,14 | 0,12–0,19 | 0,16–0,25 | 0,20–0,31 | 0,23–0,36 | 0,25–0,40 | 0,31–0,48 | 0,38–0,60 | |

| 3 | 60 | 80 | 100 | mm/U | 0,07–0,15 | 0,09–0,17 | 0,12–0,23 | 0,14–0,29 | 0,17–0,34 | 0,19–0,38 | 0,24–0,44 | 0,30–0,56 | |

| N | 1 | 90 | 200 | 300 | mm/U | 0,08–0,14 | 0,10–0,16 | 0,12–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 |

| 2 | 90 | 180 | 270 | mm/U | 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,44 | 0,32–0,52 | |

| 3 | 90 | 160 | 230 | mm/U | 0,12–0,14 | 0,13–0,16 | 0,14–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,44 | |

| 4 | 80 | 120 | 160 | mm/U | 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,48 | |

| S | 1 | 10 | 20 | 30 | mm/U | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 |

| 2 | 10 | 20 | 30 | mm/U | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |

| 3 | 15 | 25 | 35 | mm/U | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |

| 4 | 20 | 30 | 40 | mm/U | 0,03–0,05 | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,05–0,11 | 0,07–0,12 | 0,08–0,13 | 0,09–0,14 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Zoll | |||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||||

| Min. | Startwert | Max. | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| P | 0 | 260 | 360 | 460 | IPR (Zoll/U) | .002–.005 | .003–.006 | .004–.008 | .004–.009 | .005–.010 | .006–.012 | .006–.012 | .009–.018 |

| 1 | 230 | 330 | 430 | IPR (Zoll/U) | .003–.006 | .003–.006 | .004–.009 | .005–.010 | .006–.012 | .007–.014 | .007–.014 | .011–.021 | |

| 2 | 230 | 330 | 360 | IPR (Zoll/U) | .003–.006 | .003–.006 | .005–.009 | .006–.010 | .007–.012 | .008–.014 | .008–.014 | .012–.021 | |

| 3 | 200 | 260 | 330 | IPR (Zoll/U) | .003–.006 | .004–.007 | .005–.009 | .006–.011 | .008–.013 | .009–.015 | .009–.015 | .013–.023 | |

| 4 | 160 | 200 | 230 | IPR (Zoll/U) | .003–.006 | .003–.007 | .005–.009 | .006–.011 | .007–.013 | .008–.015 | .008–.015 | .011–.023 | |

| 5 | 160 | 200 | 230 | IPR (Zoll/U) | .001–.004 | .002–.004 | .002–.004 | .002–.006 | .003–.007 | .004–.008 | .006–.009 | .006–.010 | |

| 6 | 130 | 160 | 200 | IPR (Zoll/U) | .001–.003 | .002–.004 | .002–.004 | .002–.006 | .003–.007 | .004–.008 | .006–.009 | .006–.010 | |

| M | 1 | 100 | 130 | 160 | IPR (Zoll/U) | .002–.003 | .002–.004 | .003–.004 | .004–.005 | .004–.006 | .005–.006 | .006–.007 | .006–.008 |

| 2 | 130 | 160 | 200 | IPR (Zoll/U) | .002–.003 | .002–.004 | .003–.004 | .004–.005 | .004–.006 | .005–.006 | .006–.007 | .006–.008 | |

| 3 | 100 | 130 | 160 | IPR (Zoll/U) | .001–.003 | .002–.004 | .002–.004 | .003–.005 | .004–.005 | .004–.006 | .005–.007 | .006–.008 | |

| K | 1 | 260 | 390 | 520 | IPR (Zoll/U) | .004–.006 | .005–.008 | .006–.011 | .008–.013 | .009–.016 | .010–.017 | .012–.021 | .015–.027 |

| 2 | 230 | 360 | 460 | IPR (Zoll/U) | .004–.006 | .005–.008 | .006–.010 | .008–.012 | .009–.014 | .010–.016 | .012–.019 | .015–.024 | |

| 3 | 200 | 260 | 330 | IPR (Zoll/U) | .003–.006 | .004–.007 | .005–.009 | .006–.011 | .007–.013 | .008–.015 | .009–.017 | .012–.022 | |

| N | 1 | 300 | 660 | 980 | IPR (Zoll/U) | .003–.006 | .004–.006 | .005–.008 | .006–.009 | .008–.011 | .009–.013 | .011–.016 | .013–.019 |

| 2 | 300 | 590 | 890 | IPR (Zoll/U) | .003–.006 | .004–.008 | .005–.009 | .006–.011 | .008–.013 | .009–.014 | .011–.017 | .013–.021 | |

| 3 | 300 | 520 | 750 | IPR (Zoll/U) | .005–.006 | .005–.006 | .006–.008 | .006–.009 | .008–.011 | .009–.013 | .011–.016 | .013–.017 | |

| 4 | 260 | 390 | 520 | IPR (Zoll/U) | .003–.006 | .004–.008 | .005–.009 | .006–.011 | .008–.013 | .009–.014 | .011–.016 | .013–.019 | |

| S | 1 | 30 | 70 | 100 | IPR (Zoll/U) | .001–.003 | .002–.004 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .005–.007 | .006–.008 |

| 2 | 30 | 70 | 100 | IPR (Zoll/U) | .001–.003 | .002–.004 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .005–.007 | .006–.008 | |

| 3 | 50 | 80 | 110 | IPR (Zoll/U) | .001–.003 | .002–.004 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .005–.007 | .006–.008 | |

| 4 | 70 | 100 | 130 | IPR (Zoll/U) | .001–.002 | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.005 | .003–.005 | .004–.006 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | |||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||||

| Min. | Startwert | Max. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| P | 0 | 80 | 110 | 140 | mm/r | 0,06–0,12 | 0,07–0,14 | 0,09–0,19 | 0,11–0,22 | 0,13–0,26 | 0,15–0,30 | 0,15–0,30 | 0,24–0,46 |

| 1 | 70 | 100 | 130 | mm/r | 0,07–0,14 | 0,08–0,16 | 0,11–0,22 | 0,13–0,26 | 0,15–0,31 | 0,18–0,35 | 0,18–0,35 | 0,28–0,54 | |

| 2 | 70 | 100 | 110 | mm/r | 0,07–0,14 | 0,08–0,16 | 0,12–0,22 | 0,14–0,26 | 0,17–0,31 | 0,20–0,35 | 0,20–0,35 | 0,31–0,53 | |

| 3 | 60 | 80 | 100 | mm/r | 0,08–0,15 | 0,09–0,17 | 0,13–0,23 | 0,15–0,28 | 0,19–0,33 | 0,22–0,38 | 0,22–0,38 | 0,34–0,59 | |

| 4 | 50 | 60 | 70 | mm/r | 0,07–0,14 | 0,08–0,17 | 0,12–0,23 | 0,14–0,28 | 0,17–0,33 | 0,19–0,38 | 0,19–0,38 | 0,29–0,59 | |

| 5 | 50 | 60 | 70 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,14–0,24 | 0,16–0,26 | |

| 6 | 40 | 50 | 60 | mm/r | 0,03–0,08 | 0,04–0,10 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,14–0,24 | 0,16–0,26 | |

| M | 1 | 30 | 40 | 50 | mm/r | 0,04–0,07 | 0,05–0,09 | 0,07–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 |

| 2 | 40 | 50 | 60 | mm/r | 0,04–0,07 | 0,06–0,10 | 0,07–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 | |

| 3 | 30 | 40 | 50 | mm/r | 0,03–0,07 | 0,05–0,09 | 0,06–0,11 | 0,08–0,12 | 0,09–0,13 | 0,11–0,15 | 0,13–0,17 | 0,15–0,19 | |

| K | 1 | 80 | 120 | 160 | mm/r | 0,10–0,15 | 0,12–0,20 | 0,16–0,28 | 0,20–0,34 | 0,23–0,40 | 0,25–0,44 | 0,31–0,54 | 0,38–0,68 |

| 2 | 70 | 110 | 140 | mm/r | 0,10–0,14 | 0,12–0,19 | 0,16–0,25 | 0,20–0,31 | 0,23–0,36 | 0,25–0,40 | 0,31–0,48 | 0,38–0,60 | |

| 3 | 60 | 80 | 100 | mm/r | 0,07–0,15 | 0,09–0,17 | 0,12–0,23 | 0,14–0,29 | 0,17–0,34 | 0,19–0,38 | 0,24–0,44 | 0,30–0,56 | |

| N | 1 | 90 | 200 | 300 | mm/r | 0,08–0,14 | 0,10–0,16 | 0,12–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 |

| 2 | 90 | 180 | 270 | mm/r | 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,44 | 0,32–0,52 | |

| 3 | 90 | 160 | 230 | mm/r | 0,12–0,14 | 0,13–0,16 | 0,14–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,44 | |

| 4 | 80 | 120 | 160 | mm/r | 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,48 | |

| S | 1 | 10 | 20 | 30 | mm/r | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 |

| 2 | 10 | 20 | 30 | mm/r | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |

| 3 | 15 | 25 | 35 | mm/r | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |

| 4 | 20 | 30 | 40 | mm/r | 0,03–0,05 | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,05–0,11 | 0,07–0,12 | 0,08–0,13 | 0,09–0,14 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | 2,0 | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| P | 0 | 80 | 120 | 160 | mm/U | 0,04–0,10 | 0,06–0,12 | 0,07–0,14 | 0,09–0,19 | 0,11–0,22 | 0,13–0,26 | 0,15–0,30 | 0,19–0,36 | 0,24–0,46 |

| 1 | 70 | 100 | 140 | mm/U | 0,05–0,12 | 0,07–0,14 | 0,08–0,16 | 0,11–0,22 | 0,13–0,26 | 0,15–0,31 | 0,18–0,35 | 0,22–0,42 | 0,28–0,54 | |

| 2 | 90 | 120 | 140 | mm/U | 0,05–0,12 | 0,07–0,14 | 0,08–0,16 | 0,12–0,22 | 0,14–0,26 | 0,17–0,31 | 0,20–0,35 | 0,24–0,42 | 0,31–0,53 | |

| 3 | 60 | 80 | 100 | mm/U | 0,06–0,13 | 0,08–0,15 | 0,09–0,17 | 0,13–0,23 | 0,15–0,28 | 0,19–0,33 | 0,22–0,38 | 0,26–0,47 | 0,34–0,59 | |

| 4 | 50 | 80 | 100 | mm/U | 0,06–0,13 | 0,07–0,15 | 0,08–0,17 | 0,12–0,23 | 0,14–0,28 | 0,17–0,33 | 0,19–0,38 | 0,23–0,47 | 0,29–0,59 | |

| 5 | 50 | 60 | 80 | mm/U | 0,06–0,12 | 0,08–0,13 | 0,10–0,15 | 0,12–0,19 | 0,16–0,24 | 0,20–0,27 | 0,24–0,30 | 0,28–0,38 | 0,32–0,44 | |

| 6 | 40 | 50 | 70 | mm/U | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,14 | 0,10–0,18 | 0,13–0,22 | 0,14–0,24 | 0,18–0,32 | 0,23–0,41 | |

| M | 1 | 30 | 40 | 50 | mm/U | 0,03–0,06 | 0,04–0,07 | 0,05–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 |

| 2 | 40 | 50 | 60 | mm/U | 0,03–0,07 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,09–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | |

| 3 | 30 | 40 | 50 | mm/U | 0,03–0,06 | 0,04–0,07 | 0,05–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 | |

| K | 1 | 90 | 130 | 170 | mm/U | 0,09–0,17 | 0,11–0,22 | 0,12–0,24 | 0,16–0,31 | 0,20–0,38 | 0,23–0,44 | 0,25–0,49 | 0,31–0,60 | 0,38–0,74 |

| 2 | 80 | 120 | 150 | mm/U | 0,11–0,15 | 0,12–0,16 | 0,13–0,19 | 0,16–0,25 | 0,20–0,31 | 0,23–0,36 | 0,25–0,40 | 0,31–0,48 | 0,38–0,60 | |

| 3 | 70 | 90 | 110 | mm/U | 0,07–0,15 | 0,08–0,17 | 0,09–0,19 | 0,12–0,25 | 0,14–0,30 | 0,17–0,35 | 0,19–0,40 | 0,24–0,48 | 0,30–0,60 | |

| N | 1 | 90 | 230 | 315 | mm/U | 0,06–0,13 | 0,08–0,14 | 0,10–0,16 | 0,12–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 |

| 2 | 90 | 225 | 270 | mm/U | 0,06–0,12 | 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,44 | 0,32–0,52 | |

| 3 | 90 | 180 | 270 | mm/U | 0,11–0,14 | 0,12–0,14 | 0,13–0,16 | 0,14–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,44 | |

| 4 | 90 | 135 | 180 | mm/U | 0,06–0,12 | 0,08–0,16 | 0,01–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,48 | |

| S | 1 | 10 | 20 | 30 | mm/U | 0,02–0,07 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 |

| 2 | 10 | 20 | 30 | mm/U | 0,02–0,07 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |

| 3 | 15 | 25 | 35 | mm/U | 0,02–0,07 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |

| 4 | 20 | 30 | 40 | mm/U | 0,02–0,04 | 0,03–0,05 | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,05–0,11 | 0,07–0,12 | 0,08–0,13 | 0,09–0,14 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Zoll | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | 5/64 .078 | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| P | 0 | 260 | 390 | 520 | IPR (Zoll/U) | .002–.004 | .002–.005 | .003–.005 | .004–.007 | .004–.009 | .005–.010 | .006–.012 | .007–.014 | .009–.018 |

| 1 | 230 | 330 | 460 | IPR (Zoll/U) | .002–.005 | .003–.006 | .003–.006 | .004–.009 | .005–.010 | .006–.012 | .007–.014 | .009–.017 | .011–.021 | |

| 2 | 300 | 390 | 460 | IPR (Zoll/U) | .002–.005 | .003–.006 | .003–.006 | .005–.009 | .006–.010 | .007–.012 | .008–.014 | .009–.017 | .012–.021 | |

| 3 | 200 | 260 | 330 | IPR (Zoll/U) | .002–.005 | .003–.006 | .004–.007 | .005–.009 | .006–.011 | .008–.013 | .009–.015 | .010–.019 | .013–.023 | |

| 4 | 160 | 260 | 330 | IPR (Zoll/U) | .002–.005 | .003–.006 | .003–.007 | .005–.009 | .006–.011 | .007–.013 | .008–.015 | .009–.019 | .011–.023 | |

| 5 | 160 | 200 | 260 | IPR (Zoll/U) | .002–.005 | .003–.005 | .004–.006 | .005–.008 | .006–.009 | .008–.011 | .009–.012 | .011–.015 | .013–.017 | |

| 6 | 130 | 160 | 230 | IPR (Zoll/U) | .002–.002 | .002–.003 | .002–.004 | .003–.006 | .004–.007 | .005–.009 | .006–.009 | .007–.013 | .009–.016 | |

| M | 1 | 100 | 130 | 160 | IPR (Zoll/U) | .001–.002 | .002–.003 | .002–.004 | .003–.004 | .004–.005 | .004–.006 | .005–.006 | .006–.007 | .006–.008 |

| 2 | 130 | 160 | 200 | IPR (Zoll/U) | .001–.003 | .002–.003 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | |

| 3 | 100 | 130 | 160 | IPR (Zoll/U) | .001–.002 | .002–.003 | .002–.004 | .003–.004 | .004–.005 | .004–.006 | .005–.006 | .006–.007 | .006–.008 | |

| K | 1 | 300 | 430 | 560 | IPR (Zoll/U) | .004–.007 | .004–.009 | .005–.009 | .006–.012 | .008–.015 | .009–.017 | .010–.019 | .012–.024 | .015–.029 |

| 2 | 260 | 390 | 490 | IPR (Zoll/U) | .004–.006 | .005–.006 | .005–.008 | .006–.010 | .008–.012 | .009–.014 | .010–.016 | .012–.019 | .015–.024 | |

| 3 | 230 | 300 | 360 | IPR (Zoll/U) | .003–.006 | .003–.007 | .004–.008 | .005–.010 | .006–.012 | .007–.014 | .008–.016 | .009–.019 | .012–.024 | |

| N | 1 | 300 | 750 | 1030 | IPR (Zoll/U) | .002–.005 | .003–.006 | .004–.006 | .005–.008 | .006–.009 | .008–.011 | .009–.013 | .011–.016 | .013–.019 |

| 2 | 300 | 740 | 890 | IPR (Zoll/U) | .002–.005 | .003–.006 | .004–.008 | .005–.009 | .006–.011 | .008–.013 | .009–.014 | .011–.017 | .013–.021 | |

| 3 | 300 | 590 | 890 | IPR (Zoll/U) | .004–.006 | .005–.006 | .005–.006 | .006–.008 | .006–.009 | .008–.011 | .009–.013 | .011–.016 | .013–.017 | |

| 4 | 300 | 440 | 590 | IPR (Zoll/U) | .002–.005 | .003–.006 | .000–.008 | .005–.009 | .006–.011 | .008–.013 | .009–.014 | .011–.016 | .013–.019 | |

| S | 1 | 30 | 70 | 100 | IPR (Zoll/U) | .001–.003 | .001–.003 | .002–.004 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .005–.007 | .006–.008 |

| 2 | 30 | 70 | 100 | IPR (Zoll/U) | .001–.003 | .001–.003 | .002–.004 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .005–.007 | .006–.008 | |

| 3 | 50 | 80 | 110 | IPR (Zoll/U) | .001–.003 | .001–.003 | .002–.004 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .005–.007 | .006–.008 | |

| 4 | 70 | 100 | 130 | IPR (Zoll/U) | .001–.002 | .001–.002 | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.005 | .003–.005 | .004–.006 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | 2,0 | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| P | 0 | 80 | 120 | 160 | mm/r | 0,04–0,10 | 0,06–0,12 | 0,07–0,14 | 0,09–0,19 | 0,11–0,22 | 0,13–0,26 | 0,15–0,30 | 0,19–0,36 | 0,24–0,46 |

| 1 | 70 | 100 | 140 | mm/r | 0,05–0,12 | 0,07–0,14 | 0,08–0,16 | 0,11–0,22 | 0,13–0,26 | 0,15–0,31 | 0,18–0,35 | 0,22–0,42 | 0,28–0,54 | |

| 2 | 90 | 120 | 140 | mm/r | 0,05–0,12 | 0,07–0,14 | 0,08–0,16 | 0,12–0,22 | 0,14–0,26 | 0,17–0,31 | 0,20–0,35 | 0,24–0,42 | 0,31–0,53 | |

| 3 | 60 | 80 | 100 | mm/r | 0,06–0,13 | 0,08–0,15 | 0,09–0,17 | 0,13–0,23 | 0,15–0,28 | 0,19–0,33 | 0,22–0,38 | 0,26–0,47 | 0,34–0,59 | |

| 4 | 50 | 80 | 100 | mm/r | 0,06–0,13 | 0,07–0,15 | 0,08–0,17 | 0,12–0,23 | 0,14–0,28 | 0,17–0,33 | 0,19–0,38 | 0,23–0,47 | 0,29–0,59 | |

| 5 | 50 | 60 | 80 | mm/r | 0,06–0,12 | 0,08–0,13 | 0,10–0,15 | 0,12–0,19 | 0,16–0,24 | 0,20–0,27 | 0,24–0,30 | 0,28–0,38 | 0,32–0,44 | |

| 6 | 40 | 50 | 70 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,08–0,14 | 0,10–0,18 | 0,13–0,22 | 0,14–0,24 | 0,18–0,32 | 0,23–0,41 | |

| M | 1 | 30 | 40 | 50 | mm/r | 0,03–0,06 | 0,04–0,07 | 0,05–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 |

| 2 | 40 | 50 | 60 | mm/r | 0,03–0,07 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,09–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | |

| 3 | 30 | 40 | 50 | mm/r | 0,03–0,06 | 0,04–0,07 | 0,05–0,09 | 0,08–0,11 | 0,09–0,12 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,16–0,20 | |

| K | 1 | 90 | 130 | 170 | mm/r | 0,09–0,17 | 0,11–0,22 | 0,12–0,24 | 0,16–0,31 | 0,20–0,38 | 0,23–0,44 | 0,25–0,49 | 0,31–0,60 | 0,38–0,74 |

| 2 | 80 | 120 | 150 | mm/r | 0,11–0,15 | 0,12–0,16 | 0,13–0,19 | 0,16–0,25 | 0,20–0,31 | 0,23–0,36 | 0,25–0,40 | 0,31–0,48 | 0,38–0,60 | |

| 3 | 70 | 90 | 110 | mm/r | 0,07–0,15 | 0,08–0,17 | 0,09–0,19 | 0,12–0,25 | 0,14–0,30 | 0,17–0,35 | 0,19–0,40 | 0,24–0,48 | 0,30–0,60 | |

| N | 1 | 90 | 230 | 315 | mm/r | 0,06–0,13 | 0,08–0,14 | 0,10–0,16 | 0,12–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 |

| 2 | 90 | 225 | 270 | mm/r | 0,06–0,12 | 0,08–0,16 | 0,10–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,44 | 0,32–0,52 | |

| 3 | 90 | 180 | 270 | mm/r | 0,11–0,14 | 0,12–0,14 | 0,13–0,16 | 0,14–0,20 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,44 | |

| 4 | 90 | 135 | 180 | mm/r | 0,06–0,12 | 0,08–0,16 | 0,01–0,20 | 0,12–0,24 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,48 | |

| S | 1 | 10 | 20 | 30 | mm/r | 0,02–0,07 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 |

| 2 | 10 | 20 | 30 | mm/r | 0,02–0,07 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |

| 3 | 15 | 25 | 35 | mm/r | 0,02–0,07 | 0,03–0,08 | 0,04–0,09 | 0,06–0,11 | 0,07–0,12 | 0,09–0,14 | 0,10–0,15 | 0,12–0,17 | 0,14–0,19 | |

| 4 | 20 | 30 | 40 | mm/r | 0,02–0,04 | 0,03–0,05 | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,05–0,11 | 0,07–0,12 | 0,08–0,13 | 0,09–0,14 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use