Produkt ähnlich wie:

KenTIP™ FS • Bohrergrundkörper • 8 x D • SCF-Schaft • Metrisch

Modulares Bohren • Flanschschaft mit Spannfläche (SCF)

Material Nummer6372620

ISO Katalog NummerKTFS150R08SCF20MANSI Katalog NummerKTFS150R08SCF20M

- P Stahl

- M Rostfreier Stahl

- K Gusseisen

- S Hochwarmfeste Legierungen

Drilling: Stacked Plates

Drilling - Through Coolant

Zylinderschaft – mit Spannfläche

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Überblick

- Anwendungsdaten

- Herunterladen

- Kompatible Teile Maschinenseite

- Kompatible Teile Werkstückseite

- Ersatzteile

- Bewertung

- F&A

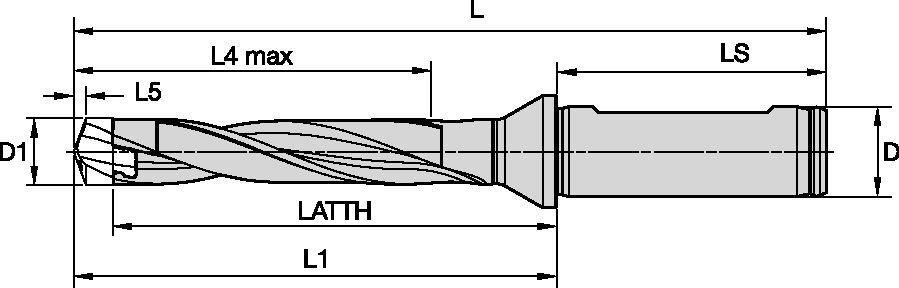

| Material Nummer | 6372620 |

| ISO Katalog Nummer | KTFS150R08SCF20M |

| ANSI Katalog Nummer | KTFS150R08SCF20M |

| [D1] Bohrerdurchmesser M | 15 mm |

| [D1] Bohrerdurchmesser M | 0.5906 in |

| [D1MAX] Bohrerdurchmesser max. | 15.999 mm |

| [D1MAX] Bohrerdurchmesser max. | 0.6299 in |

| [L4] Maximale Bohrtiefe | 128 mm |

| [L4] Maximale Bohrtiefe | 5.039 in |

| [L] Gesamtlänge | 205 mm |

| [L] Gesamtlänge | 8.0709 in |

| [LATTH] Wendeschneidplatte-Befestigung LG Halter | 146.3 mm |

| [LATTH] Wendeschneidplatte-Befestigung LG Halter | 5.7598 in |

| [L1] Messlänge der Wendeschneidplatte | 155 mm |

| [L1] Messlänge der Wendeschneidplatte | 6.1024 in |

| [LS] Schaftlänge | 50 mm |

| [LS] Schaftlänge | 1.9685 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 20 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 0.7874 in |

| [SSC] Wendeschneidplatten-Sitz-Größe | T |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Gusseisen

- Hochwarmfeste Legierungen

Uses and application

Drilling: Stacked Plates

Drilling - Through Coolant

Zylinderschaft – mit Spannfläche

Features and benefits

- Große, ultra-hochpolierte Spannuten garantieren einen ungehinderten Spanfluss und damit eine hohe Standzeit und eine höhere Leistung.

- Mit der Kühlmittelzuführung zur Bohrerspitze und zur Spanfläche wird das Kühlmittel garantiert an die Stellen zugeführt, wo es benötigt wird.

- Jeder Bohrerkörper wird mit dem KenTIP FS Smart-Schlüssel geliefert. Das einfache Austauschen der Schneidkörper in der Maschine reduziert die Maschinenstillstandszeit und spart Geld.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Toleranz

| Toleranz • metrisch | |

| D1 metrisch | Toleranz k8 |

| 6 | 0,000/+0,018 |

| 0,000/+0,022 | |

| 0,000/+0,027 | |

| 0,000/+0,033 | |

| Toleranz • Zoll | |

| D1 Zoll | Toleranz k8 |

| 0.2362 | 0.0000/+0.0007 |

| 0.0000/+0.0009 | |

| 0.0000/+0.0011 | |

| 0.0000/+0.0013 | |

Anwendungsdaten

| Werkstoffgruppe | Schnittgeschwindigkeit | Zoll | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | .236 | .315 | .394 | .472 | .551 | .630 | .787 | .945 | 1.023 | |||

| P | 0 | 315 | 415 | 575 | IPR (Zoll/U) | .004 | .004 | .005 | .006 | .007 | .007 | .009 | .011 | .011 |

| 1 | 300 | 430 | 560 | IPR (Zoll/U) | .004 | .004 | .005 | .006 | .007 | .007 | .009 | .011 | .011 | |

| 2 | 330 | 460 | 590 | IPR (Zoll/U) | .004 | .004 | .005 | .006 | .007 | .007 | .009 | .011 | .011 | |

| 3 | 200 | 330 | 430 | IPR (Zoll/U) | .004 | .004 | .005 | .006 | .006 | .007 | .009 | .012 | .012 | |

| 4 | 200 | 330 | 430 | IPR (Zoll/U) | .004 | .004 | .005 | .006 | .006 | .007 | .009 | .010 | .010 | |

| 5 | 200 | 260 | 330 | IPR (Zoll/U) | .004 | .004 | .004 | .005 | .006 | .006 | .008 | .009 | .010 | |

| 6 | 200 | 230 | 260 | IPR (Zoll/U) | .004 | .004 | .004 | .005 | .006 | .006 | .008 | .009 | .010 | |

| K | 1 | 260 | 400 | 560 | IPR (Zoll/U) | .005 | .005 | .006 | .007 | .009 | .010 | .012 | .014 | .015 |

| 2 | 260 | 360 | 390 | IPR (Zoll/U) | .005 | .005 | .006 | .007 | .009 | .010 | .012 | .014 | .015 | |

| 3 | 160 | 260 | 330 | IPR (Zoll/U) | .004 | .005 | .005 | .006 | .007 | .008 | .011 | .013 | .013 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| P | 0 | 95 | 125 | 175 | mm/U | 0,10 | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,24 | 0,28 | 0,29 |

| 1 | 90 | 130 | 170 | mm/U | 0,10 | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,24 | 0,28 | 0,29 | |

| 2 | 100 | 140 | 180 | mm/U | 0,10 | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,24 | 0,28 | 0,29 | |

| 3 | 60 | 100 | 130 | mm/U | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,18 | 0,23 | 0,30 | 0,31 | |

| 4 | 60 | 100 | 130 | mm/U | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,18 | 0,23 | 0,25 | 0,26 | |

| 5 | 60 | 80 | 100 | mm/U | 0,09 | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,20 | 0,24 | 0,25 | |

| 6 | 60 | 70 | 80 | mm/U | 0,09 | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,20 | 0,24 | 0,25 | |

| K | 1 | 80 | 120 | 170 | mm/U | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 |

| 2 | 80 | 110 | 120 | mm/U | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 | |

| 3 | 50 | 80 | 100 | mm/U | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,21 | 0,28 | 0,32 | 0,33 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| P | 0 | 95 | 125 | 175 | mm/r | 0,10 | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,24 | 0,28 | 0,29 |

| 1 | 90 | 130 | 170 | mm/r | 0,10 | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,24 | 0,28 | 0,29 | |

| 2 | 100 | 140 | 180 | mm/r | 0,10 | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,24 | 0,28 | 0,29 | |

| 3 | 60 | 100 | 130 | mm/r | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,18 | 0,23 | 0,30 | 0,31 | |

| 4 | 60 | 100 | 130 | mm/r | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,18 | 0,23 | 0,25 | 0,26 | |

| 5 | 60 | 80 | 100 | mm/r | 0,09 | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,20 | 0,24 | 0,25 | |

| 6 | 60 | 70 | 80 | mm/r | 0,09 | 0,10 | 0,11 | 0,12 | 0,14 | 0,16 | 0,20 | 0,24 | 0,25 | |

| K | 1 | 80 | 120 | 170 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 |

| 2 | 80 | 110 | 120 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 | |

| 3 | 50 | 80 | 100 | mm/r | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,21 | 0,28 | 0,32 | 0,33 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| M | 1 | 50 | 60 | 90 | mm/U | 0,07 | 0,08 | 0,09 | 0,11 | 0,12 | 0,13 | 0,16 | 0,19 | 0,20 |

| 2 | 30 | 60 | 90 | mm/U | 0,07 | 0,08 | 0,09 | 0,11 | 0,12 | 0,13 | 0,16 | 0,19 | 0,20 | |

| 3 | 20 | 50 | 60 | mm/U | 0,07 | 0,08 | 0,09 | 0,11 | 0,12 | 0,13 | 0,16 | 0,19 | 0,20 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Zoll | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | .236 | .315 | .394 | .472 | .551 | .630 | .787 | .945 | 1.023 | |||

| M | 1 | 160 | 200 | 300 | IPR (Zoll/U) | .003 | .003 | .004 | .004 | .005 | .005 | .006 | .007 | .008 |

| 2 | 100 | 200 | 300 | IPR (Zoll/U) | .003 | .003 | .004 | .004 | .005 | .005 | .006 | .007 | .008 | |

| 3 | 70 | 160 | 200 | IPR (Zoll/U) | .003 | .003 | .004 | .004 | .005 | .005 | .006 | .007 | .008 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| M | 1 | 50 | 60 | 90 | mm/r | 0,07 | 0,08 | 0,09 | 0,11 | 0,12 | 0,13 | 0,16 | 0,19 | 0,20 |

| 2 | 30 | 60 | 90 | mm/r | 0,07 | 0,08 | 0,09 | 0,11 | 0,12 | 0,13 | 0,16 | 0,19 | 0,20 | |

| 3 | 20 | 50 | 60 | mm/r | 0,07 | 0,08 | 0,09 | 0,11 | 0,12 | 0,13 | 0,16 | 0,19 | 0,20 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| K | 1 | 100 | 175 | 200 | mm/U | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 |

| 2 | 100 | 160 | 180 | mm/U | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 | |

| 3 | 70 | 85 | 120 | mm/U | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 | 0,21 | 0,28 | 0,32 | 0,33 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Zoll | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | .236 | .315 | .394 | .472 | .551 | .630 | .787 | .945 | 1.023 | |||

| K | 1 | 330 | 570 | 660 | IPR (Zoll/U) | .005 | .005 | .006 | .007 | .009 | .010 | .012 | .014 | .015 |

| 2 | 330 | 520 | 590 | IPR (Zoll/U) | .005 | .005 | .006 | .007 | .009 | .010 | .012 | .014 | .015 | |

| 3 | 230 | 280 | 390 | IPR (Zoll/U) | .004 | .005 | .005 | .006 | .007 | .008 | .011 | .013 | .013 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| K | 1 | 100 | 175 | 200 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 |

| 2 | 100 | 160 | 180 | mm/r | 0,12 | 0,14 | 0,16 | 0,19 | 0,23 | 0,26 | 0,30 | 0,36 | 0,37 | |

| 3 | 70 | 85 | 120 | mm/r | 0,11 | 0,13 | 0,15 | 0,17 | 0,19 – 0,42 | 0,21 | 0,28 | 0,32 | 0,33 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | |||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||

| Min. | Startwert | Max. | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| S | 4 | 10 | 13 | 20 | mm/U | 0,02–0,08 | 0,03–0,10 | 0,04–0,12 | 0,05–0,16 | 0,05–0,18 | 0,06–0,20 |

| N | 1 | 100 | 230 | 270 | mm/U | 0,13–0,22 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 |

| 2 | 100 | 220 | 270 | mm/U | 0,14–0,23 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,52 | |

| 3 | 90 | 180 | 230 | mm/U | 0,13–0,22 | 0,16–0,24 | 0,20–0,28 | 0,24–0,32 | 0,28–0,40 | 0,32–0,48 | |

| 4 | 90 | 130 | 200 | mm/U | 0,10–0,18 | 0,16–0,28 | 0,20–0,32 | 0,24–0,36 | 0,28–0,40 | 0,32–0,52 | |

| C | 2 | 70 | 110 | 140 | mm/U | 0,03-0,10 | 0,04-0,12 | 0,05-0,15 | 0,05-0,18 | 0,06-0,21 | 0,07-0,23 |

| 3 | 10 | 13 | 20 | mm/U | 0,02-0,08 | 0,03-0,10 | 0,04-0,12 | 0,05-0,16 | 0,05-0,18 | 0,06-0,20 | |

| 4 | 10 | 20 | 40 | mm/U | 0,02-0,08 | 0,03-0,10 | 0,04-0,12 | 0,05-0,16 | 0,05-0,18 | 0,06-0,20 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Zoll | |||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||

| Min. | Startwert | Max. | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| S | 4 | 30 | 40 | 70 | IPR | .001–.003 | .001–.004 | .002–.005 | .002–.006 | .002–.007 | .002–.008 |

| N | 1 | 330 | 750 | 890 | IPR | .005–.009 | .006–.009 | .008–.011 | .009–.013 | .011–.016 | .013–.019 |

| 2 | 330 | 720 | 890 | IPR | .006–.009 | .006–.011 | .008–.013 | .009–.014 | .011–.017 | .013–.021 | |

| 3 | 300 | 590 | 750 | IPR | .005–.009 | .006–.009 | .008–.011 | .009–.013 | .011–.016 | .013–.019 | |

| 4 | 300 | 430 | 660 | IPR | .004–.007 | .006–.011 | .008–.013 | .009–.014 | .011–.016 | .013–.019 | |

| C | 4 | 230 | 360 | 460 | IPR (Zoll/min) | .001-.004 | .002-.005 | .002-.006 | .002-.007 | .002-.008 | .003-.009 |

| 4 | 30 | 40 | 70 | IPR (Zoll/min) | .001-.003 | .001-.004 | .002-.005 | .002-.006 | .002-.007 | .002-.008 | |

| 4 | 30 | 70 | 130 | IPR (Zoll/min) | .001-.003 | .001-.004 | .002-.005 | .002-.006 | .002-.007 | .002-.008 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | |||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||

| Min. | Startwert | Max. | 6.0 | 8.0 | 10.0 | 12.0 | 16.0 | 20.0 | |||

| S | 4 | 10 | 13 | 20 | mm/r | 0.02~0.08 | 0.03~0.10 | 0.04~0.12 | 0.05~0.16 | 0.05~0.18 | 0.06~0.20 |

| N | 1 | 100 | 230 | 270 | mm/r | 0.13~0.22 | 0.16~0.24 | 0.20~0.28 | 0.24~0.32 | 0.28~0.40 | 0.32~0.48 |

| 2 | 100 | 220 | 270 | mm/r | 0.14~0.23 | 0.16~0.28 | 0.20~0.32 | 0.24~0.36 | 0.28~0.40 | 0.32~0.52 | |

| 3 | 90 | 180 | 230 | mm/r | 0.13~0.22 | 0.16~0.24 | 0.20~0.28 | 0.24~0.32 | 0.28~0.40 | 0.32~0.48 | |

| 4 | 90 | 130 | 200 | mm/r | 0.10~0.18 | 0.16~0.28 | 0.20~0.32 | 0.24~0.36 | 0.28~0.40 | 0.32~0.52 | |

| C | 2 | 70 | 110 | 140 | mm/r | 0.03~0.10 | 0.04~0.12 | 0.05~0.15 | 0.05~0.18 | 0.06~0.21 | 0.07~0.23 |

| 3 | 10 | 13 | 20 | mm/r | 0.02~0.08 | 0.03~0.10 | 0.04~0.12 | 0.05~0.16 | 0.05~0.18 | 0.06~0.20 | |

| 4 | 10 | 20 | 40 | mm/r | 0.02~0.08 | 0.03~0.10 | 0.04~0.12 | 0.05~0.16 | 0.05~0.18 | 0.06~0.20 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Zoll | |||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||

| Min. | Startwert | Max. | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| C | 1 | 260 | 330 | 490 | IPR | 0,002 | 0,002 | 0,002 | 0,002 | 0,002 | 0,002 |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | |||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||

| Min. | Startwert | Max. | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| C | 1 | 80 | 100 | 150 | mm/U | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | |||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||

| Min. | Startwert | Max. | 6,0 | 8.0 | 10.0 | 12.0 | 16.0 | 20.0 | |||

| C | 1 | 80 | 100 | 150 | mm/r | 0.05~0.20 | 0.05~0.20 | 0.05~0.20 | 0.05~0.20 | 0.05~0.20 | 0.05~0.20 |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| P | 0 | 110 | 140 | 170 | mm/U | 0,10–0,19 | 0,11–0,22 | 0,13–0,24 | 0,15–0,26 | 0,17–0,29 | 0,19–0,31 | 0,21–0,34 | 0,23–0,38 | 0,24–0,40 |

| 1 | 110 | 140 | 170 | mm/U | 0,10–0,19 | 0,11–0,22 | 0,13–0,24 | 0,15–0,26 | 0,17–0,29 | 0,19–0,31 | 0,21–0,34 | 0,23–0,38 | 0,24–0,40 | |

| 2 | 100 | 120 | 140 | mm/U | 0,10–0,19 | 0,11–0,22 | 0,13–0,24 | 0,15–0,26 | 0,17–0,29 | 0,19–0,31 | 0,21–0,34 | 0,23–0,38 | 0,24–0,40 | |

| 3 | 80 | 100 | 120 | mm/U | 0,10–0,17 | 0,11–0,20 | 0,12–0,22 | 0,14–0,24 | 0,16–0,26 | 0,18–0,28 | 0,20–0,31 | 0,21–0,35 | 0,22–0,36 | |

| 4 | 70 | 90 | 110 | mm/U | 0,10–0,17 | 0,11–0,20 | 0,12–0,22 | 0,14–0,24 | 0,16–0,26 | 0,18–0,28 | 0,20–0,31 | 0,21–0,35 | 0,22–0,36 | |

| 5 | 60 | 80 | 100 | mm/U | 0,09–0,16 | 0,10–0,18 | 0,11–0,20 | 0,13–0,22 | 0,15–0,24 | 0,16–0,26 | 0,18–0,29 | 0,19–0,33 | 0,20–0,34 | |

| 6 | 60 | 80 | 100 | mm/U | 0,09–0,16 | 0,10–0,18 | 0,11–0,20 | 0,13–0,22 | 0,15–0,24 | 0,16–0,26 | 0,18–0,29 | 0,19–0,33 | 0,20–0,34 | |

| M | 1 | 40 | 60 | 80 | mm/U | 0,07–0,12 | 0,08–0,14 | 0,09–0,16 | 0,11–0,18 | 0,12–0,20 | 0,13–0,22 | 0,14–0,24 | 0,15–0,26 | 0,16–0,27 |

| 2 | 35 | 55 | 70 | mm/U | 0,07–0,12 | 0,08–0,14 | 0,09–0,16 | 0,11–0,18 | 0,12–0,20 | 0,13–0,22 | 0,14–0,24 | 0,15–0,26 | 0,16–0,27 | |

| K | 1 | 90 | 120 | 175 | mm/U | 0,12-0,21 | 0,14-0,24 | 0,16-0,28 | 0,18-0,32 | 0,20-0,36 | 0,22-0,40 | 0,25-0,44 | 0,28-0,48 | 0,29-0,50 |

| 2 | 80 | 110 | 140 | mm/U | 0,12–0,21 | 0,14–0,24 | 0,16–0,28 | 0,18–0,32 | 0,20–0,36 | 0,22–0,40 | 0,25–0,44 | 0,28–0,48 | 0,29–0,50 | |

| 3 | 70 | 80 | 100 | mm/U | 0,11-0,19 | 0,13-0,22 | 0,14-0,25 | 0,16-0,28 | 0,18-0,32 | 0,21-0,36 | 0,23-0,40 | 0,26-0,44 | 0,27-0,46 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Zoll | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | .236 | .315 | .394 | .472 | .551 | .630 | .787 | .945 | 1.023 | |||

| P | 0 | 360 | 460 | 560 | IPR (Zoll/U) | 0.004–0.007 | 0.004–0.009 | 0.005–0.009 | 0.006–0.010 | 0.007–0.011 | 0.007–0.012 | 0.008–0.013 | 0.009–0.015 | 0.009–0.016 |

| 1 | 360 | 460 | 560 | IPR (Zoll/U) | 0.004–0.007 | 0.004–0.009 | 0.005–0.009 | 0.006–0.010 | 0.007–0.011 | 0.007–0.012 | 0.008–0.013 | 0.009–0.015 | 0.009–0.016 | |

| 2 | 330 | 400 | 460 | IPR (Zoll/U) | 0.004–0.007 | 0.004–0.009 | 0.005–0.009 | 0.006–0.010 | 0.007–0.011 | 0.007–0.012 | 0.008–0.013 | 0.009–0.015 | 0.009–0.016 | |

| 3 | 260 | 330 | 400 | IPR (Zoll/U) | 0.004–0.007 | 0.004–0.008 | 0.005–0.009 | 0.006–0.009 | 0.006–0.010 | 0.007–0.011 | 0.008–0.012 | 0.008–0.014 | 0.009–0.014 | |

| 4 | 230 | 330 | 360 | IPR (Zoll/U) | 0.004–0.007 | 0.004–0.008 | 0.005–0.009 | 0.006–0.009 | 0.006–0.010 | 0.007–0.011 | 0.008–0.012 | 0.008–0.014 | 0.009–0.014 | |

| 5 | 200 | 260 | 330 | IPR (Zoll/U) | 0.004–0.006 | 0.004–0.007 | 0.004–0.008 | 0.005–0.009 | 0.006–0.009 | 0.006–0.010 | 0.007–0.011 | 0.007–0.013 | 0.008–0.013 | |

| 6 | 200 | 260 | 330 | IPR (Zoll/U) | 0.004–0.006 | 0.004–0.007 | 0.004–0.008 | 0.005–0.009 | 0.006–0.009 | 0.006–0.010 | 0.007–0.011 | 0.007–0.013 | 0.008–0.013 | |

| M | 1 | 130 | 200 | 260 | IPR (Zoll/U) | 0.003–0.005 | 0.003–0.006 | 0.004–0.006 | 0.004–0.007 | 0.005–0.008 | 0.005–0.009 | 0.006–0.009 | 0.006–0.010 | 0.006–0.011 |

| 2 | 120 | 180 | 230 | IPR (Zoll/U) | 0.003–0.005 | 0.003–0.006 | 0.004–0.006 | 0.004–0.007 | 0.005–0.008 | 0.005–0.009 | 0.006–0.009 | 0.006–0.010 | 0.006–0.011 | |

| K | 1 | 300 | 400 | 580 | IPR (Zoll/U) | 0.005-0.008 | 0.006-0.009 | 0.006-0.011 | 0.007-0.013 | 0.008-0.014 | 0.009-0.016 | 0.010-0.017 | 0.011-0.019 | 0.011-0.020 |

| 2 | 260 | 360 | 460 | IPR (Zoll/U) | 0.005–0.008 | 0.006–0.009 | 0.006–0.011 | 0.007–0.013 | 0.008–0.014 | 0.009–0.016 | 0.010–0.017 | 0.011–0.019 | 0.011–0.020 | |

| 3 | 230 | 260 | 330 | IPR (Zoll/U) | 0.004-0.007 | 0.005-0.009 | 0.006-0.010 | 0.006-0.011 | 0.007-0.013 | 0.008-0.014 | 0.009-0.016 | 0.010-0.017 | 0.011-0.018 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | ||||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | |||||||||||||

| Min. | Startwert | Max. | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| P | 0 | 110 | 140 | 170 | mm/r | 0,10–0,19 | 0,11–0,22 | 0,13–0,24 | 0,15–0,26 | 0,17–0,29 | 0,19–0,31 | 0,21–0,34 | 0,23–0,38 | 0,24–0,40 |

| 1 | 110 | 140 | 170 | mm/r | 0,10–0,19 | 0,11–0,22 | 0,13–0,24 | 0,15–0,26 | 0,17–0,29 | 0,19–0,31 | 0,21–0,34 | 0,23–0,38 | 0,24–0,40 | |

| 2 | 100 | 120 | 140 | mm/r | 0,10–0,19 | 0,11–0,22 | 0,13–0,24 | 0,15–0,26 | 0,17–0,29 | 0,19–0,31 | 0,21–0,34 | 0,23–0,38 | 0,24–0,40 | |

| 3 | 80 | 100 | 120 | mm/r | 0,10–0,17 | 0,11–0,20 | 0,12–0,22 | 0,14–0,24 | 0,16–0,26 | 0,18–0,28 | 0,20–0,31 | 0,21–0,35 | 0,22–0,36 | |

| 4 | 70 | 90 | 110 | mm/r | 0,10–0,17 | 0,11–0,20 | 0,12–0,22 | 0,14–0,24 | 0,16–0,26 | 0,18–0,28 | 0,20–0,31 | 0,21–0,35 | 0,22–0,36 | |

| 5 | 60 | 80 | 100 | mm/r | 0,09–0,16 | 0,10–0,18 | 0,11–0,20 | 0,13–0,22 | 0,15–0,24 | 0,16–0,26 | 0,18–0,29 | 0,19–0,33 | 0,20–0,34 | |

| 6 | 60 | 80 | 100 | mm/r | 0,09–0,16 | 0,10–0,18 | 0,11–0,20 | 0,13–0,22 | 0,15–0,24 | 0,16–0,26 | 0,18–0,29 | 0,19–0,33 | 0,20–0,34 | |

| M | 1 | 40 | 60 | 80 | mm/r | 0,07–0,12 | 0,08–0,14 | 0,09–0,16 | 0,11–0,18 | 0,12–0,20 | 0,13–0,22 | 0,14–0,24 | 0,15–0,26 | 0,16–0,27 |

| 2 | 35 | 55 | 70 | mm/r | 0,07–0,12 | 0,08–0,14 | 0,09–0,16 | 0,11–0,18 | 0,12–0,20 | 0,13–0,22 | 0,14–0,24 | 0,15–0,26 | 0,16–0,27 | |

| K | 1 | 90 | 120 | 175 | mm/r | 0,12-0,21 | 0,14-0,24 | 0,16-0,28 | 0,18-0,32 | 0,20-0,36 | 0,22-0,40 | 0,25-0,44 | 0,28-0,48 | 0,29-0,50 |

| 2 | 80 | 110 | 140 | mm/r | 0,12–0,21 | 0,14–0,24 | 0,16–0,28 | 0,18–0,32 | 0,20–0,36 | 0,22–0,40 | 0,25–0,44 | 0,28–0,48 | 0,29–0,50 | |

| 3 | 70 | 80 | 100 | mm/r | 0,11-0,19 | 0,13-0,22 | 0,14-0,25 | 0,16-0,28 | 0,18-0,32 | 0,21-0,36 | 0,23-0,40 | 0,26-0,44 | 0,27-0,46 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | |||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||||

| Min. | Startwert | Max. | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| P | 0 | 70 | 125 | 175 | mm/r | 0,09–0,18 | 0,10–0,21 | 0,12–0,24 | 0,14–0,30 | 0,18–0,36 | 0,23–0,42 | 0,27–0,48 | 0,28–0,50 |

| 1 | 70 | 120 | 170 | mm/r | 0,09–0,18 | 0,10–0,22 | 0,12–0,24 | 0,14–0,30 | 0,18–0,36 | 0,23–0,42 | 0,27–0,48 | 0,28–0,50 | |

| 2 | 90 | 135 | 180 | mm/r | 0,09–0,18 | 0,10–0,25 | 0,12–0,27 | 0,14–0,33 | 0,18–0,39 | 0,23–0,45 | 0,27–0,51 | 0,28–0,50 | |

| 3 | 60 | 95 | 130 | mm/r | 0,09–0,16 | 0,10–0,28 | 0,11–0,29 | 0,13–0,33 | 0,17–0,37 | 0,22–0,41 | 0,28–0,45 | 0,30–0,46 | |

| 4 | 50 | 90 | 130 | mm/r | 0,09–0,16 | 0,10–0,28 | 0,11–0,29 | 0,13–0,33 | 0,17–0,37 | 0,22–0,41 | 0,24–0,45 | 0,25–0,46 | |

| 5 | 30 | 65 | 100 | mm/r | 0,09–0,15 | 0,10–0,18 | 0,10–0,22 | 0,11–0,27 | 0,15–0,32 | 0,19–0,37 | 0,23–0,42 | 0,24–0,43 | |

| 6 | 40 | 60 | 80 | mm/r | 0,09–0,15 | 0,09–0,18 | 0,10–0,22 | 0,10–0,27 | 0,15–0,32 | 0,19–0,37 | 0,23–0,42 | 0,24–0,43 | |

| M | 1 | 20 | 55 | 90 | mm/r | 0,07–0,12 | 0,08–0,13 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,15–0,26 | 0,18–0,27 | 0,19–0,28 |

| 2 | 30 | 60 | 90 | mm/r | 0,07–0,12 | 0,08–0,13 | 0,08–0,16 | 0,10–0,18 | 0,12–0,22 | 0,15–0,26 | 0,18–0,27 | 0,19–0,28 | |

| 3 | 20 | 40 | 60 | mm/r | 0,07–0,12 | 0,08–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,22 | 0,15–0,26 | 0,18–0,27 | 0,19–0,28 | |

| K | 1 | 80 | 140 | 200 | mm/r | 0,11–0,26 | 0,13–0,32 | 0,15–0,44 | 0,18–0,49 | 0,25–0,58 | 0,29–0,64 | 0,35–0,70 | 0,36–0,75 |

| 2 | 80 | 130 | 180 | mm/r | 0,11–0,26 | 0,13–0,31 | 0,15–0,36 | 0,18–0,40 | 0,25–0,48 | 0,29–0,60 | 0,35–0,70 | 0,36–0,75 | |

| 3 | 70 | 95 | 120 | mm/r | 0,10-0,22 | 0,12-0,25 | 0,15-0,35 | 0,16-0,40 | 0,20-0,48 | 0,26-0,60 | 0,30-0,63 | 0,32-0,65 | |

| S | 1 | 10 | 20 | 30 | mm/r | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,13 | 0,10–0,15 | 0,11–0,17 | 0,12–0,19 | 0,13–0,21 |

| 2 | 10 | 20 | 30 | mm/r | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,13 | 0,10–0,15 | 0,11–0,17 | 0,12–0,19 | 0,13–0,21 | |

| 3 | 15 | 25 | 35 | mm/r | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,13 | 0,10–0,15 | 0,11–0,17 | 0,12–0,19 | 0,13–0,21 | |

| 4 | 20 | 30 | 40 | mm/r | 0,04–0,07 | 0,05–0,09 | 0,05–0,10 | 0,07–0,12 | 0,08–0,13 | 0,08–0,13 | 0,09–0,15 | 0,10–0,17 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Zoll | |||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||||

| Min. | Startwert | Max. | .236 | .315 | .394 | .472 | .630 | .787 | .945 | 1.023 | |||

| P | 0 | 230 | 410 | 570 | IPR | .004–.007 | .004–.008 | .005–.009 | .006–.012 | .007–.014 | .009–.016 | .011–.019 | .011–.020 |

| 1 | 230 | 390 | 560 | IPR | .004–.007 | .004–.009 | .005–.009 | .006–.012 | .007–.014 | .009–.016 | .011–.019 | .011–.020 | |

| 2 | 300 | 440 | 590 | IPR | .004–.007 | .004–.010 | .005–.011 | .006–.013 | .007–.015 | .009–.018 | .011–.020 | .011–.020 | |

| 3 | 200 | 310 | 430 | IPR | .004–.006 | .004–.011 | .004–.011 | .005–.013 | .007–.015 | .009–.016 | .011–.018 | .012–.018 | |

| 4 | 160 | 300 | 430 | IPR | .004–.006 | .004–.011 | .004–.011 | .005–.013 | .007–.015 | .009–.016 | .009–.018 | .010–.018 | |

| 5 | 100 | 210 | 330 | IPR | .004–.006 | .004–.007 | .004–.009 | .004–.011 | .006–.013 | .008–.015 | .009–.016 | .009–.017 | |

| 6 | 130 | 200 | 260 | IPR | .004–.006 | .004–.007 | .004–.009 | .004–.011 | .006–.013 | .008–.015 | .009–.016 | .009–.017 | |

| M | 1 | 70 | 180 | 300 | IPR | .003–.005 | .003–.005 | .003–.006 | .004–.007 | .005–.009 | .006–.010 | .007–.011 | .008–.011 |

| 2 | 100 | 200 | 300 | IPR | .003–.005 | .003–.005 | .003–.006 | .004–.007 | .005–.009 | .006–.010 | .007–.011 | .008–.011 | |

| 3 | 70 | 130 | 200 | IPR | .003–.005 | .003–.005 | .003–.006 | .004–.006 | .005–.009 | .006–.010 | .007–.011 | .008–.011 | |

| K | 1 | 260 | 460 | 660 | IPR | .004–.010 | .005–.013 | .006–.017 | .007–.019 | .010–.023 | .011–.025 | .014–.028 | .014–.030 |

| 2 | 260 | 430 | 590 | IPR | .004–.010 | .005–.012 | .006–.014 | .007–.016 | .010–.019 | .011–.024 | .014–.028 | .014–.030 | |

| 3 | 230 | 310 | 390 | IPR | .004–.009 | .005–.010 | .006–.014 | .006–.016 | .008–.019 | .010–.024 | .012–.025 | .013–.026 | |

| S | 1 | 30 | 70 | 100 | IPR | .002–.004 | .002–.004 | .003–.005 | .003–.005 | .004–.006 | .004–.007 | .005–.008 | .005–.008 |

| 2 | 30 | 70 | 100 | IPR | .002–.004 | .002–.004 | .003–.005 | .003–.005 | .004–.006 | .004–.007 | .005–.008 | .005–.008 | |

| 3 | 50 | 80 | 110 | IPR | .002–.004 | .002–.004 | .003–.005 | .003–.005 | .004–.006 | .004–.007 | .005–.008 | .005–.008 | |

| 4 | 70 | 100 | 130 | IPR | .002–.003 | .002–.004 | .002–.004 | .003–.005 | .003–.005 | .003–.005 | .004–.006 | .004–.007 | |

| Werkstoffgruppe | Schnittgeschwindigkeit | Metrisch | |||||||||||

| Bereich | Empfohlener Vorschub pro Umdrehung | ||||||||||||

| Min. | Startwert | Max. | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | 24,0 | 26,0 | |||

| P | 0 | 70 | 125 | 175 | mm/r | 0,09–0,18 | 0,10–0,21 | 0,12–0,24 | 0,14–0,30 | 0,18–0,36 | 0,23–0,42 | 0,27–0,48 | 0,28–0,50 |

| 1 | 70 | 120 | 170 | mm/r | 0,09–0,18 | 0,10–0,22 | 0,12–0,24 | 0,14–0,30 | 0,18–0,36 | 0,23–0,42 | 0,27–0,48 | 0,28–0,50 | |

| 2 | 90 | 135 | 180 | mm/r | 0,09–0,18 | 0,10–0,25 | 0,12–0,27 | 0,14–0,33 | 0,18–0,39 | 0,23–0,45 | 0,27–0,51 | 0,28–0,50 | |

| 3 | 60 | 95 | 130 | mm/r | 0,09–0,16 | 0,10–0,28 | 0,11–0,29 | 0,13–0,33 | 0,17–0,37 | 0,22–0,41 | 0,28–0,45 | 0,30–0,46 | |

| 4 | 50 | 90 | 130 | mm/r | 0,09–0,16 | 0,10–0,28 | 0,11–0,29 | 0,13–0,33 | 0,17–0,37 | 0,22–0,41 | 0,24–0,45 | 0,25–0,46 | |

| 5 | 30 | 65 | 100 | mm/r | 0,09–0,15 | 0,10–0,18 | 0,10–0,22 | 0,11–0,27 | 0,15–0,32 | 0,19–0,37 | 0,23–0,42 | 0,24–0,43 | |

| 6 | 40 | 60 | 80 | mm/r | 0,09–0,15 | 0,09–0,18 | 0,10–0,22 | 0,10–0,27 | 0,15–0,32 | 0,19–0,37 | 0,23–0,42 | 0,24–0,43 | |

| M | 1 | 20 | 55 | 90 | mm/r | 0,07–0,12 | 0,08–0,13 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,15–0,26 | 0,18–0,27 | 0,19–0,28 |

| 2 | 30 | 60 | 90 | mm/r | 0,07–0,12 | 0,08–0,13 | 0,08–0,16 | 0,10–0,18 | 0,12–0,22 | 0,15–0,26 | 0,18–0,27 | 0,19–0,28 | |

| 3 | 20 | 40 | 60 | mm/r | 0,07–0,12 | 0,08–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,22 | 0,15–0,26 | 0,18–0,27 | 0,19–0,28 | |

| K | 1 | 80 | 140 | 200 | mm/r | 0,11–0,26 | 0,13–0,32 | 0,15–0,44 | 0,18–0,49 | 0,25–0,58 | 0,29–0,64 | 0,35–0,70 | 0,36–0,75 |

| 2 | 80 | 130 | 180 | mm/r | 0,11–0,26 | 0,13–0,31 | 0,15–0,36 | 0,18–0,40 | 0,25–0,48 | 0,29–0,60 | 0,35–0,70 | 0,36–0,75 | |

| 3 | 70 | 95 | 120 | mm/r | 0,10-0,22 | 0,12-0,25 | 0,15-0,35 | 0,16-0,40 | 0,20-0,48 | 0,26-0,60 | 0,30-0,63 | 0,32-0,65 | |

| S | 1 | 10 | 20 | 30 | mm/r | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,13 | 0,10–0,15 | 0,11–0,17 | 0,12–0,19 | 0,13–0,21 |

| 2 | 10 | 20 | 30 | mm/r | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,13 | 0,10–0,15 | 0,11–0,17 | 0,12–0,19 | 0,13–0,21 | |

| 3 | 15 | 25 | 35 | mm/r | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,13 | 0,10–0,15 | 0,11–0,17 | 0,12–0,19 | 0,13–0,21 | |

| 4 | 20 | 30 | 40 | mm/r | 0,04–0,07 | 0,05–0,09 | 0,05–0,10 | 0,07–0,12 | 0,08–0,13 | 0,08–0,13 | 0,09–0,15 | 0,10–0,17 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use

![KTIP SCHLUESSEL D=14.00[0.552]-16.99[0.6 KTIP SCHLUESSEL D=14.00[0.552]-16.99[0.6](https://images.kennametal.com/is/image/Kennametal/43601?$PRODUCT-REFERENCE-THUMBNAIL-IMAGE$)