Peak performance and longevity are often areas top of mind when it comes to road construction —especially the parts used for road milling drums during the height of the season. But after the season is over, evaluating your drum’s condition is critical for next season’s performance. Here, we'll delve into several tactics you should use in the off-season to make sure your milling drums are ready every season.

Understanding Parts Wear

Peak performance and longevity are often areas top of mind when it comes to road construction —especially the parts used for road milling drums during the height of the season. But after the season is over, evaluating your drum’s condition is critical for next season’s performance. Here, we'll delve into several tactics you should use in the off-season to make sure your milling drums are ready every season.

Understanding Parts Wear

Parts wear refers to the gradual deterioration or loss of material from components due to abrasion, harsh usage, heavy impact, or other forms of stress during regular operation. Additionally, poor maintenance and lack of component care can significantly shorten your equipment’s lifecycle production time.

Key advantages of off-season maintenance include:

Preventive Maintenance: Wear parts are designed to endure friction, abrasion, and impact during regular equipment operation. By regularly replacing these parts, the overall integrity of the equipment is preserved, preventing more costly repairs and in-season downtime.

Efficient Replacements: identifying replaceable worn parts can be performed quickly and minimize downtime. This increases production and ensures that machinery is operational for longer.

Performance: Components like blades, cutting edges, or paddles that wear down over time can significantly impact the efficiency of milling drums. Replacing or repositioning them can provide consistent and reliable results in terms of cutting, material conveying, or road pattern profiling.

Safety: Worn-out parts can compromise the safety of both equipment and operators. Replaceable wear parts reduce the risk of unexpected failures, contributing to a safer working environment.

Cost-Savings: Instead of replacing entire assemblies or machinery, replaceable wear parts allow for targeted replacements of only the parts that have experienced wear.

Adaptability: Applications and environments require different wear-resistant materials and designs. Replaceable wear parts can be customized to suit specific operating conditions.

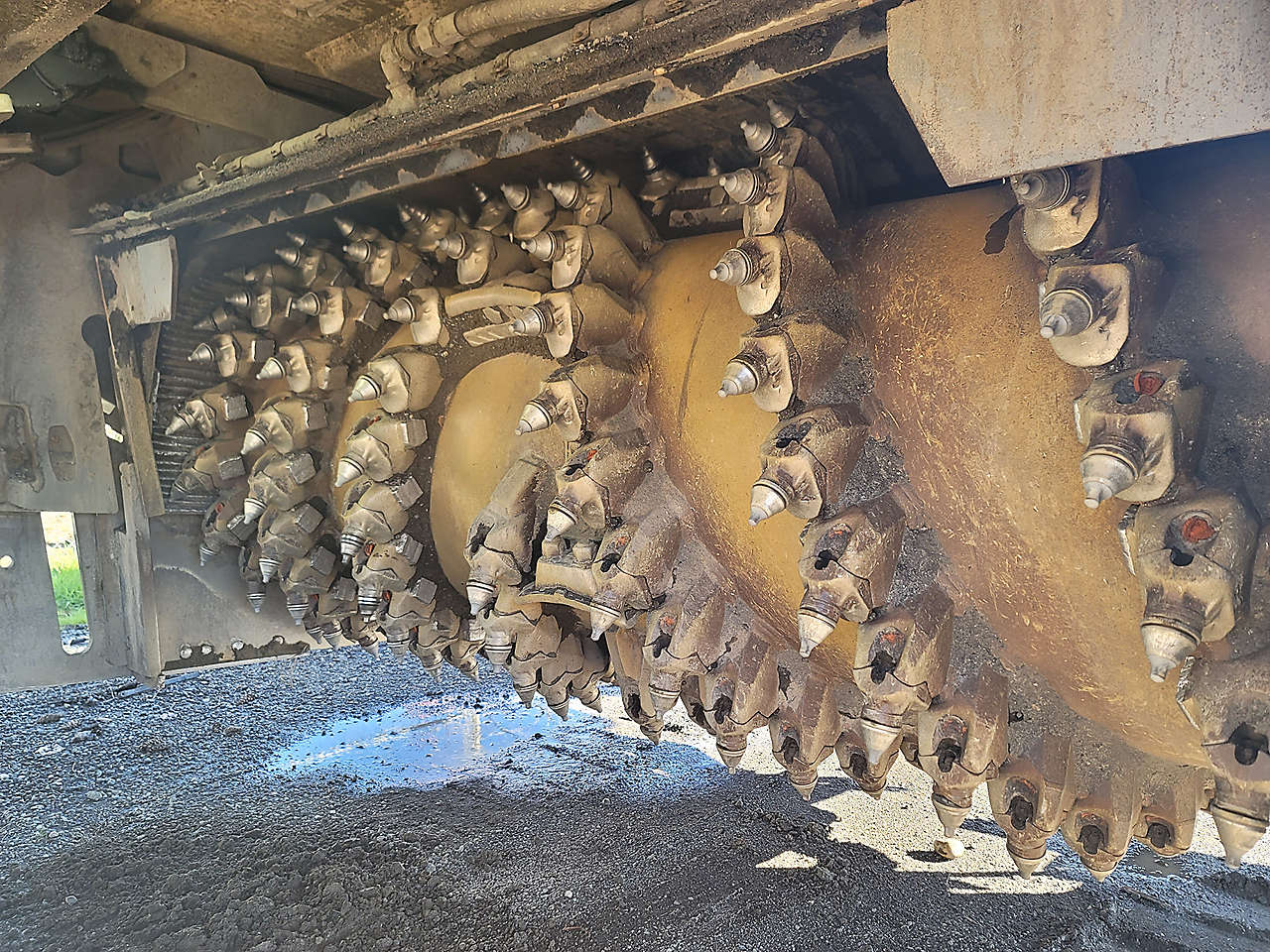

Kennametal RK4 road milling teeth.

Components to Inspect During Off-Season Maintenance

Road construction equipment is always facing challenges and the off-season is the perfect time for evaluating and replacing parts. Key components including tool holders (sleeves), kicker paddle edges, edge cutters, moldboard blades, and wear pads (skis) are common parts to inspect.

Common parts that you should inspect:

Sleeves: These can wear down due to rotation friction and exposure to abrasive conditions. You should look for cracks, chips, or excessive wear. Loose or worn sleeves and excess material build up will have a negative effect on the tool performance that can result in carbide flat spotting or fracturing.

Kicker Paddles/Plates: Used for lifting material within the housing, these paddles can experience wear, chipping, or stress during regular operation. Less effectiveness of kicker paddles increases wear on other components and reduces conveyance efficiency over time.

Edge Cutters: Essential for proper material movement within the housing. Ineffective use can lead to wear of the edge and result in an increase of unwanted energy consumption.

Moldboard Edges: Used for sealing the cut material in the housing. Hardened and wear-resistant materials for replacement edges can improve overall performance.

Ski Pads/Track Pads/Wear Pads: Designed to reduce friction and protect crucial components of the milling drum. Pads push the milling machining drum into the cut and if the pads are worn, they cannot create the force needed to push the milling drum which would affect the cutting system. Use high-quality, abrasion-resistant materials for replacement pads to significantly enhance the lifespan of the pads.

Worn out rotating PCD teeth on KPF 301 system.

Milling Drum Types

There are several types of drums for road construction. Here, we have listed some common ones.

Standard Drums: The most commonly used and versatile drum is designed for general milling applications, such as removing asphalt or concrete surfaces from roads. They are suitable for a wide range of milling tasks including routine road maintenance and resurfacing projects.

Profile Drums: Specialized for creating specific surface profiles or shapes, these drums have a unique configuration of cutting tools that allows for precise profiling of surfaces. They can be used for creating road surfaces with specific slopes, crowns, or other custom shapes.

Micro-Milling Drums: These drums provide high-level precision and have closely spaced cutting tools, allowing for smoother finishes and the removal of thin surface layers. Micro-milling drums are often used for pavement maintenance and when a smooth and precisely textured surface is required.

Custom Drums: Designed for specialized applications that require unique configurations, these drums are tailored to meet specific project needs that can’t be addressed by standard drums. They are often used in niche applications where highly customization is required.

A small wheel trencher outfitted with Kennametal SM06 teeth.

Summary

A proactive approach to maintaining your milling drums in the off-season will ensure reliability and efficiency during your road rehabilitation operations. By focusing on components like tool holders (sleeves), kicker paddle edges, edge cutters, moldboard blades, and wear pads (skis), you can address potential disruptions before performance is compromised. You will not only extend the lifespan of your milling drums but also reduce downtime and save on cost.

For more information on Road Rehabilitation, contact one of our Kennametal experts using the Contact Us button below.

Related Articles

- Buying Guide: The Road King Series of Cutters for MillingRoad rehabilitation is crucial for a smooth infrastructure. Learn about Kennametal's Road King line of conical cutting bits and what they are used for.Road rehabilitation is crucial for a smooth infrastructure. Learn about Kennametal's Road King line of conical cutting bits and what they are used for.

- Kennametal Collaboration Does Not StopKennametal tooling is helping PR Systems, a Seattle-based pavement milling company, go the distance - faster and with less downtime. Read more.Kennametal tooling is helping PR Systems, a Seattle-based pavement milling company, go the distance - faster and with less downtime. Read more.

- Unlocking the Full Value of AdditiveKennametal has end to end capabilities-from powder feedstock to finished part-so we can help customers unlock the full value of additive. Learn more.Kennametal has end to end capabilities-from powder feedstock to finished part-so we can help customers unlock the full value of additive. Learn more.

- How We Collaborate with Customers to Solve Wear IssuesKennametal’s advantage is our deep understanding of the materials – it’s the evaluation process and science behind our work. Learn more from wear expert Rob Davison.Kennametal’s advantage is our deep understanding of the materials – it’s the evaluation process and science behind our work. Learn more from wear expert Rob Davison.