5720 Series • End Mill • Screw-On • Inch

Shoulder milling cutter for high-speed aluminum machining.

物料号5672521

公制样本编号A5720VZ16SA1.25Z3R2英制样本编号A5720VZ16SA1.25Z3R2

- K 铸铁

- N 非铁材质

Spiral Circular

端面铣削

螺旋铣削

坡铣: 毛坯

刀柄 — 旋入式

铣削 — 贯通式冷却

刀座

沉孔加工

Inclined Square End Mill

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 5672521 |

| 公制样本编号 | A5720VZ16SA1.25Z3R2 |

| 英制样本编号 | A5720VZ16SA1.25Z3R2 |

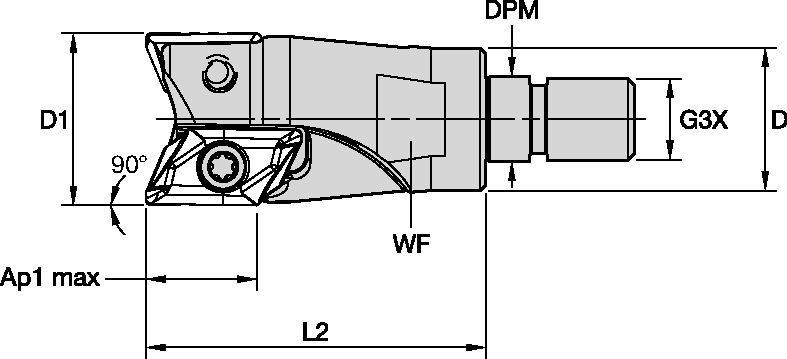

| [D1] 有效的切削直径 | 31.75 mm |

| [D1] 有效的切削直径 | 1.25 in |

| [D]适配接头/刀柄/镗孔直径 | 29 mm |

| [D]适配接头/刀柄/镗孔直径 | 1.141 in |

| [DPM] 机床侧定位孔直径 | 17 mm |

| [DPM] 机床侧定位孔直径 | .6693 in |

| [G3X] 外部连接螺纹尺寸 | M16 |

| [L2] 刀头长度 | 49.95 mm |

| [L2] 刀头长度 | 1.966 in |

| [WF] 平面宽度 | 24 mm |

| [WF] 平面宽度 | .9449 in |

| [AP1MAX] 第一个最大切深 | 16 mm |

| [AP1MAX] 第一个最大切深 | .63 in |

| 刀片数量 | 3 |

| [Z] 排屑槽数量 | 3 |

| 最大坡铣角度 | 11.5 |

| 重量(磅) | 0.39 |

| 最大 RPM | 41500 |

工件材料

- 铸铁

- 非铁材质

Uses and application

Spiral Circular

端面铣削

螺旋铣削

坡铣: 毛坯

刀柄 — 旋入式

铣削 — 贯通式冷却

刀座

沉孔加工

Inclined Square End Mill

Features and benefits

- For pocketing and profiling in aluminum and aluminum alloys.

- Maximum stability in high-speed applications.

- Excellent choice for components with thin walls due to low cutting pressure.

- Internal coolant supply.

- Reinforced pockets for high feed applications and ramping, increasing tool and productivity.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

High Performance Combination Tools

刀片选择指南

| 5720 Series • Insert Selection Guide | ||||||

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| – | (锋利的槽型) | – | (强壮的槽型) | |||

| – | 耐磨性 |  | 韧性 | |||

| – | 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | .F..721 | GH1 | .F..721 | GH1 | .F..721 | GH1 |

| N3 | .F..721 | GH1 | .F..721 | GH1 | .F..721 | GH1 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

Feeds

推荐初始进给率 [mm]

| 5720 Series • Recommended Starting Feeds [mm/th] | |||||||||||||||

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| ...FR721 | 0,12 | 0.45 | 0.81 | 0,08 | 0.33 | 0.58 | 0,06 | 0.25 | 0.43 | 0,06 | 0.21 | 0.38 | 0,05 | 0.2 | 0.35 |

| ...ER721 | 0.15 | 0.50 | 0.92 | 0.11 | 0.36 | 0.66 | 0.08 | 0.27 | 0.5 | 0.07 | 0,24 | 0.43 | 0.07 | 0,22 | 0,40 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | |||||||||||||||

| 5720 Series • Recommended Starting Feeds [IPT] | |||||||||||||||

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| ...FR721 | 0,12 | 0.45 | 0.81 | 0,08 | 0.33 | 0.58 | 0,06 | 0.25 | 0.43 | 0,06 | 0.21 | 0.38 | 0,05 | 0.2 | 0.35 |

| ...ER721 | 0.15 | 0.50 | 0.92 | 0.11 | 0.36 | 0.66 | 0.08 | 0.27 | 0.5 | 0.07 | 0,24 | 0.43 | 0.07 | 0,22 | 0,40 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | |||||||||||||||

Speeds

推荐初始速度 [m/min]

| 5720 Series • Recommended Starting Speed [m/min] | ||||

| 刀片材质 | GH1 | |||

| 切削厚度 hex mm | 最小值 | 最大值 | ||

| 材料 分组 | 最大值 | 初始值 | 最小值 | |

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | 215 | 140 | 120 |

| 2 | 195 | 120 | 100 | |

| 3 | 180 | 105 | 80 | |

| N | 1 | 795 | 695 | 600 |

| 2 | 615 | 520 | 425 | |

| 3 | 615 | 520 | 425 | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| H | 1 | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||

| 5720 Series • Recommended Starting Speed [SFM] | ||||

| 刀片材质 | GH1 | |||

| Chip Thickness hex Inch | 最小值 | 最大值 | ||

| 材料 分组 | 最大值 | 初始值 | 最小值 | |

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | 705 | 460 | 395 |

| 2 | 640 | 395 | 330 | |

| 3 | 590 | 345 | 260 | |

| N | 1 | 2610 | 2280 | 1970 |

| 2 | 2020 | 1705 | 1395 | |

| 3 | 2020 | 1705 | 1395 | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| H | 1 | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||

I have read and accepted the Terms & Conditions of use