KOR5™ DA • Radiused • 5 Flutes • 3 x D • Internal Coolant • Safe-Lock™ Shank • Inch

KOR5™ DA Solid Carbide End Mill for Dynamic Milling of Aluminum

物料号6754924

公制样本编号KOR5RA0500R150SLR015I英制样本编号KOR5RA0500R150SLR015I

- N 非铁材质

Trochoidal Milling

Through Coolant - Solid End Mill

坡铣: 4°

刀具尺寸: 排屑槽数: 5

螺旋角: 35°

刀尖类型: 刀尖半径

刀尖类型: 方头立铣

侧铣/方肩铣削: 粗加工

侧铣/方肩铣削: 精加工

SAFE-LOCK Shank

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 6754924 |

| 公制样本编号 | KOR5RA0500R150SLR015I |

| 英制样本编号 | KOR5RA0500R150SLR015I |

| 材质 | K600 |

| 机床侧适配接头样式 | SAFE-LOCK |

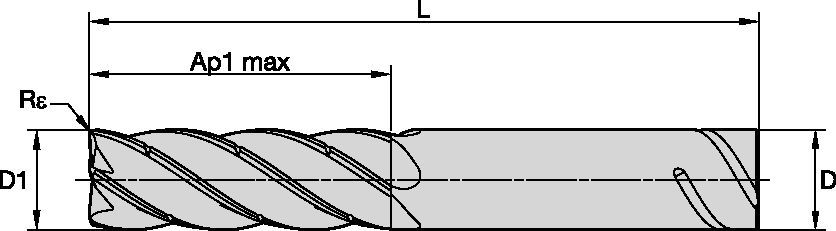

| [D]适配接头/刀柄/镗孔直径 | 12.7 mm |

| [D]适配接头/刀柄/镗孔直径 | .5 in |

| [Re] 刀尖半径 | 0.381 mm |

| [Re] 刀尖半径 | .015 in |

| [Z] 排屑槽数量 | 5 |

| [D1] 有效的切削直径 | 12.7 mm |

| [D1] 有效的切削直径 | .5 in |

| [AP1MAX] 第一个最大切深 | 38.1 mm |

| [AP1MAX] 第一个最大切深 | 1.5 in |

| [L] 总长 | 88.9 mm |

| [L] 总长 | 3.5 in |

工件材料

- 非铁材质

Uses and application

Trochoidal Milling

Through Coolant - Solid End Mill

坡铣: 4°

刀具尺寸: 排屑槽数: 5

螺旋角: 35°

刀尖类型: 刀尖半径

刀尖类型: 方头立铣

侧铣/方肩铣削: 粗加工

侧铣/方肩铣削: 精加工

SAFE-LOCK Shank

Grades

K600

采用高品质,微晶材料制成的硬质合金材质产品,可用于各种类型材料的切削加工。极高的韧性确保磨损率在可控状态。微晶材料结构确保切削刃的锋利。

Features and benefits

- Designed for trochoidal milling with low radial engagement and full length of cut.

- With chip splitters for ideal chip evacuation.

- Proprietary flute form reduces vibrations and improves tool life.

- Helix angle tailored to minimize vibration and optimize tool life.

- Front end geometry designed for maximum tool life in helical and ramping operations.

- Safe-Lock for pull out protection.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

TechnicalInfo

| Ae/D1 | 2% | 5% | 10% | 20% | 30% | 40% | 50% | 100% |

| Max Ap | Ap1 Max | Ap1 Max | Ap1 Max | Ap1 Max | 2 x D1 | 1 x D1 | .5 x D1 | .25 x D1 |

| Feed Multiplier | 3.60 | 2.30 | 1.70 | 1.25 | 1.09 | 1.02 | 1.00 | .90 |

| 0.5 x D1 | 0.25 x D1 | |||||||

| 3,60 | 2,30 | 1,70 | 1,25 | 1,09 | 1,02 | 1,00 | 0,90 |

应用数据

|  |  | |||||||||||

| 侧铣加工(A)和槽铣加工(B) | K600 | Recommended feed per tooth (IPT = inch/th) | |||||||||||

| D1 | |||||||||||||

| 材料 分组 | A | B | 切削速度 | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||

| ap | ae | ap | min | max | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| N | 1 | 0.5 x D1 | 0.5 x D1 | 0.25 x D1 | 640 | – | 6560 | IPT | 0.0030 | 0.0050 | 0.0060 | 0.0080 | 0.0090 |

| 2 | 0.5 x D1 | 0.5 x D1 | 0.25 x D1 | 640 | – | 4920 | IPT | 0.0025 | 0.0045 | 0.0055 | 0.0070 | 0.0085 | |

| 材料 分组 |  |  | K600 | 推荐每齿进给量 (fz = mm/th) | |||||||||

| A | B | 切削速度 | D1 | ||||||||||

| ap | ae | ap | 最小值 | 最大值 | mm | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | |||

| N | 1 | 0,5 x D1 | 0,5 x D1 | 0,25 x D1 | 200 | – | 2000 | fz | 0,080 | 0,120 | 0,160 | 0,200 | 0,225 |

| 2 | 0,5 x D1 | 0,5 x D1 | 0,25 x D1 | 200 | – | 1500 | fz | 0,070 | 0,110 | 0,140 | 0,180 | 0,213 | |

I have read and accepted the Terms & Conditions of use

KOR™ Series End Mills: Solid End Mills for Dynamic Milling