KSSR-RPGN.. • Shell Mills • Inch

Shell Mills

物料号1942586

公制样本编号KSSR200RP430F3英制样本编号KSSR200RP430F3

- P 钢

- S 高温合金

坡铣: 毛坯

槽铣: 球形刀尖

侧铣/方肩铣削: 球形刀尖

铣削 — 侧铣和端面铣

刀座

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

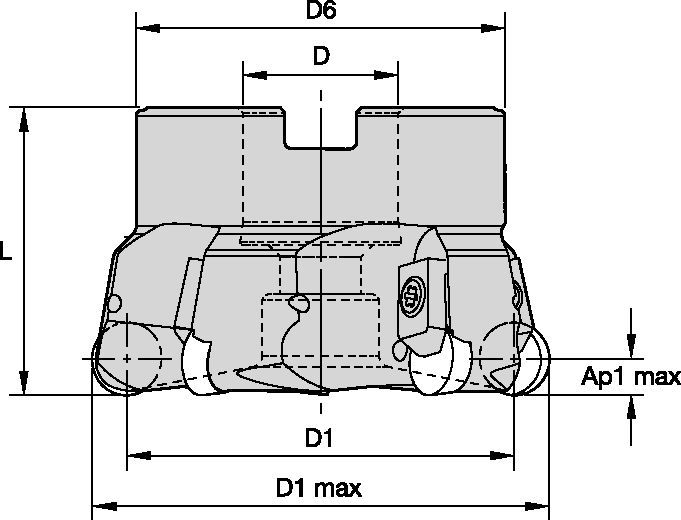

| 物料号 | 1942586 |

| 公制样本编号 | KSSR200RP430F3 |

| 英制样本编号 | KSSR200RP430F3 |

| [D1MAX] 最大切削直径 | 50.8 mm |

| [D1MAX] 最大切削直径 | 2 in |

| [D1] 有效的切削直径 | 38.22 mm |

| [D1] 有效的切削直径 | 1.505 in |

| [D]适配接头/刀柄/镗孔直径 | 19.05 mm |

| [D]适配接头/刀柄/镗孔直径 | 0.75 in |

| [D6] 保护区孔直径 | 44.45 mm |

| [D6] 保护区孔直径 | 1.75 in |

| [L] 总长 | 50.8 mm |

| [L] 总长 | 2 in |

| [AP1MAX] 第一个最大切深 | 6.33 mm |

| [AP1MAX] 第一个最大切深 | 0.249 in |

| 刀片数量 | 4 |

| 最大坡铣角度 | 3 |

| 最大 RPM | 16000 |

| Gage 刀片 | RP_43_ |

| 重量(磅) | 0.89 |

工件材料

- 钢

- 高温合金

Uses and application

坡铣: 毛坯

槽铣: 球形刀尖

侧铣/方肩铣削: 球形刀尖

铣削 — 侧铣和端面铣

刀座

Features and benefits

- For machining high-temp alloys, PH stainless, stainless steels, and hardened materials.

- Excellent productivity through massive reduction of machining time.

- Face milling, pocketing, and ramping capabilities.

- Through-body coolant delivery for internal air supply only.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

Feeds

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .005 | .005 | .007 | .004 | .004 | .005 | .003 | .003 | .004 | .003 | .003 | .004 | .003 | .003 | .004 | ..E |

| 轻切削 | 中等切削 | 重切削 |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .010 | .011 | .014 | .007 | .008 | .010 | .006 | .007 | .009 | .006 | .007 | .008 | .006 | .006 | .008 | ..E |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .005 | .006 | .008 | .004 | .004 | .006 | .004 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | ..E |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .007 | .008 | .010 | .005 | .006 | .008 | .005 | .005 | .007 | .004 | .005 | .006 | .004 | .005 | .006 | ..E |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .005 | .005 | .007 | .004 | .004 | .005 | .003 | .003 | .004 | .003 | .003 | .004 | .003 | .003 | .004 | ..E |

| ..T | .007 | .008 | .010 | .005 | .006 | .008 | .004 | .005 | .007 | .004 | .005 | .006 | .004 | .005 | .006 | ..T |

| 轻切削 | 中等切削 | 重切削 |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .005 | .006 | .008 | .004 | .004 | .006 | .004 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | ..E |

| ..T | .008 | .009 | .012 | .006 | .007 | .009 | .005 | .006 | .008 | .005 | .006 | .007 | .005 | .006 | .007 | ..T |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .010 | .011 | .014 | .007 | .008 | .010 | .006 | .007 | .009 | .006 | .007 | .008 | .006 | .006 | .008 | ..E |

| ..T | .014 | .017 | .021 | .010 | .012 | .016 | .009 | .011 | .014 | .008 | .010 | .013 | .008 | .010 | .012 | ..T |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .007 | .008 | .010 | .005 | .006 | .008 | .005 | .005 | .007 | .004 | .005 | .006 | .004 | .005 | .006 | ..E |

| ..T | .010 | .012 | .015 | .008 | .009 | .011 | .007 | .008 | .010 | .006 | .007 | .009 | .006 | .007 | .009 | ..T |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .005 | .005 | .007 | .004 | .004 | .005 | .003 | .003 | .004 | .003 | .003 | .004 | .003 | .003 | .004 | ..E |

| ..T | .007 | .010 | .011 | .005 | .008 | .009 | .004 | .007 | .007 | .004 | .006 | .007 | .004 | .006 | .007 | ..T |

| 轻切削 | 中等切削 | 重切削 |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .005 | .006 | .008 | .004 | .004 | .006 | .004 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | ..E |

| ..T | .008 | .012 | .013 | .006 | .009 | .010 | .005 | .008 | .009 | .005 | .007 | .008 | .005 | .007 | .008 | ..T |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .010 | .011 | .014 | .007 | .008 | .010 | .006 | .007 | .009 | .006 | .007 | .008 | .006 | .006 | .008 | ..E |

| ..T | .014 | .022 | .024 | .010 | .016 | .018 | .009 | .014 | .015 | .008 | .013 | .014 | .008 | .013 | .014 | ..T |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .007 | .008 | .010 | .005 | .006 | .008 | .005 | .005 | .007 | .004 | .005 | .006 | .004 | .005 | .006 | ..E |

| ..T | .010 | .016 | .017 | .008 | .012 | .013 | .007 | .010 | .011 | .006 | .010 | .010 | .006 | .009 | .010 | ..T |

Speeds

Recommended Starting Speeds [SFM]

| 材料 分组 | KYHS10 | KYSM10 | KYSP30 | KYS30 | KY2100 | KY4300 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | 3960 | 3200 | 2380 | 3000 | 2400 | 1800 | 3000 | 2400 | 1800 | 3300 | 2670 | 1980 | – | – | – | |

| 6 | – | – | – | 3960 | 3200 | 2380 | 3000 | 2400 | 1800 | 3000 | 2400 | 1800 | 3300 | 2670 | 1980 | – | – | – | |

| M | 1 | – | – | – | 3960 | 3200 | 2380 | – | – | – | – | – | – | 3300 | 2670 | 1980 | – | – | – |

| 2 | – | – | – | 3740 | 3000 | – | – | – | – | – | – | – | 3120 | 2500 | – | – | – | – | |

| 3 | – | – | – | 2760 | 2400 | – | – | – | – | – | – | – | 2300 | 2000 | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 1680 | 1320 | 960 | 3490 | 2860 | 2220 | 2640 | 2160 | 1680 | 2640 | 2160 | 1680 | 2910 | 2380 | 1850 | – | – | – |

| 2 | 1680 | 1320 | 960 | 3490 | 2860 | 2220 | 2640 | 2160 | 1680 | 2640 | 2160 | 1680 | 2910 | 2380 | 1850 | 1400 | 1100 | 800 | |

| 3 | 2400 | 2040 | 1680 | 5080 | 4130 | 3180 | 3840 | 3120 | 2400 | 3840 | 3120 | 2400 | 4230 | 3440 | 2650 | 2000 | 1700 | 1400 | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | 1200 | 1020 | 780 | – | – | – | – | – | – | – | – | – | – | – | – | 1000 | 850 | 650 |

High Performance Combination Tools

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| – | (锋利的槽型) | – | (强壮的槽型) | |||

| – | 耐磨性 |  | 韧性 | |||

| – | 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | ..E | KYSP30 | ..E | KYSP30 | ..E | KYSP30 |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ..E | KYS30 | ..E | KYS30 | ..E | KYS30 |

| S3 | ..E | KYS30 | ..E | KYS30 | ..E | KYS30 |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

RPG32… High Temp

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| – | (锋利的槽型) | – | (强壮的槽型) | |||

| – | 耐磨性 |  | 韧性 | |||

| – | 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | ..E | KYSP30 | ..E | KYSP30 | ..E | KYSP30 |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ..E | KYS30 | ..E | KYS30 | ..E | KYS30 |

| S3 | ..E | KYS30 | ..E | KYS30 | ..E | KYS30 |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

RPG43… High Temp

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| – | (锋利的槽型) | – | (强壮的槽型) | |||

| – | 耐磨性 |  | 韧性 | |||

| – | 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | ..E | KYSP30 | ..E | KYSP30 | ..E | KYSP30 |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ..E | KYS30 | ..E | KYS30 | ..T | KYS30 |

| S3 | ..E | KYS30 | ..T | KYS30 | ..T | KYS30 |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use