Q: What industries are most suitable to take advantage of Kennametal’s additive manufacturing solutions and what do they gain from moving to these solutions?

We see great opportunity for our additive solutions to improve the life cycle and design flexibility of components in several markets that experience extreme wear. We have many successful examples within oil and gas applications, as well as sever other markets; includingautomotive, aerospace, pump components, and general process industries where our advanced component wear solutions offer advantages.

Our customers are trying to get the best possible performance at the lowest total cost of ownership. Additively manufactured parts are not necessarily the lowest cost product, but the long-term wear benefits can result in a lower total cost of ownership.

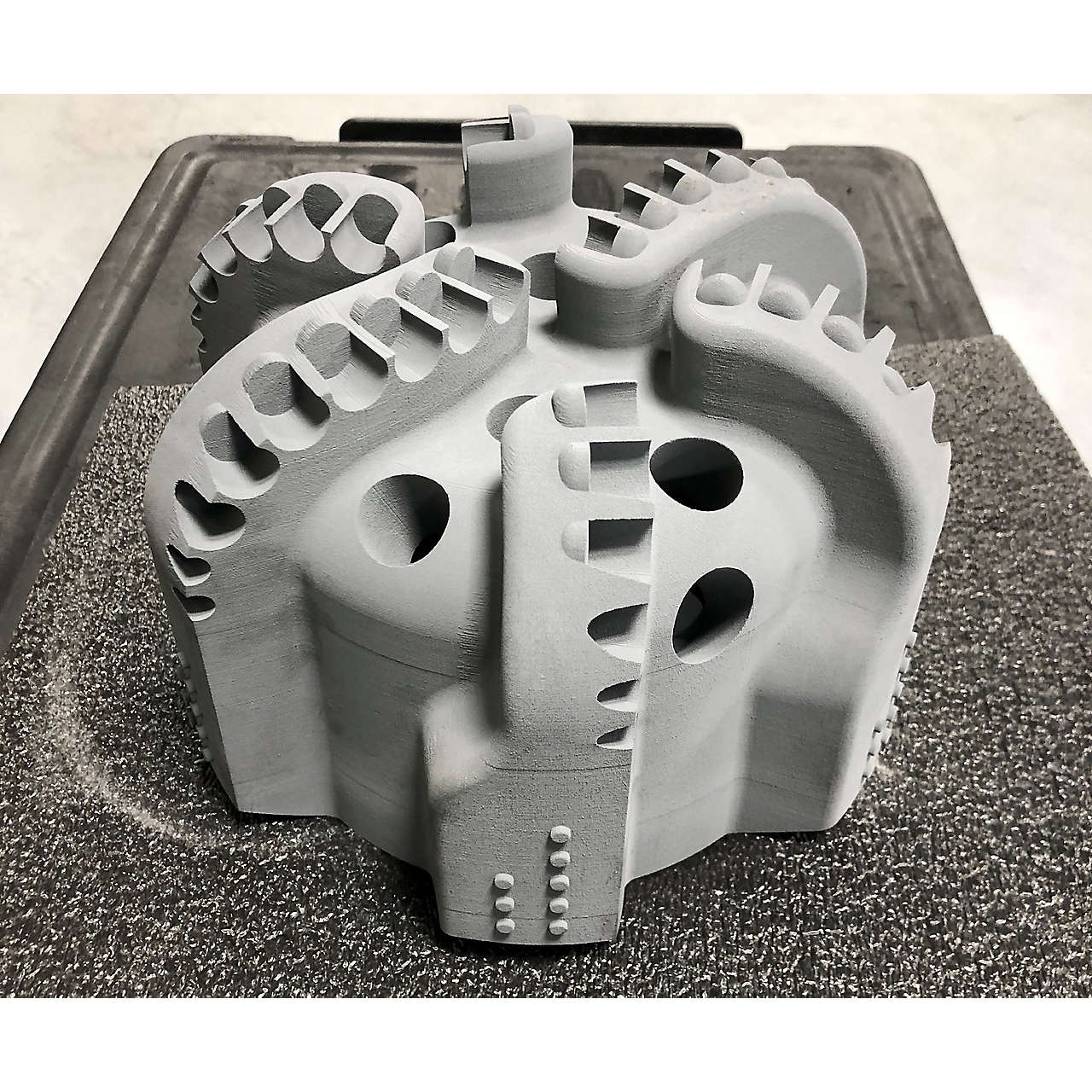

We prove the capabilities ofadditive manufacturingto our customers by providing technical data on Kennametal’s proprietary developed grades, test coupons, functioning prototypes, and production components.

That is one of the best parts of my job-educating customers about the potential with additive manufacturing and, in turn, helping them find the right solution for their application.