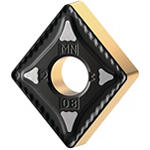

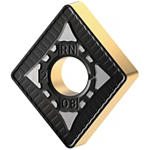

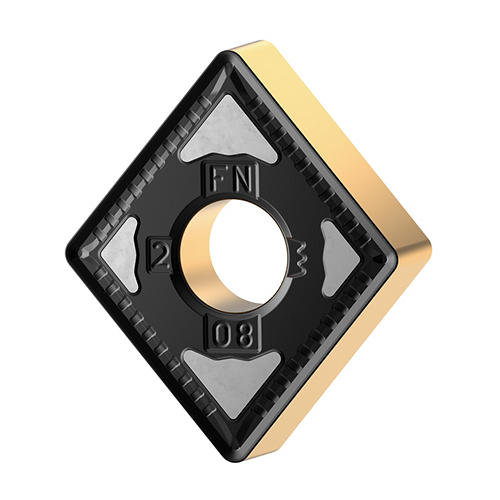

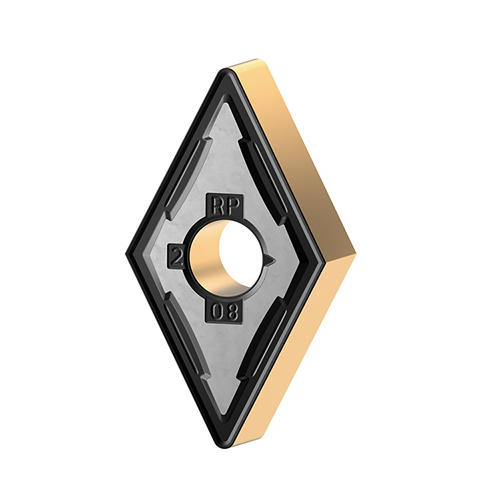

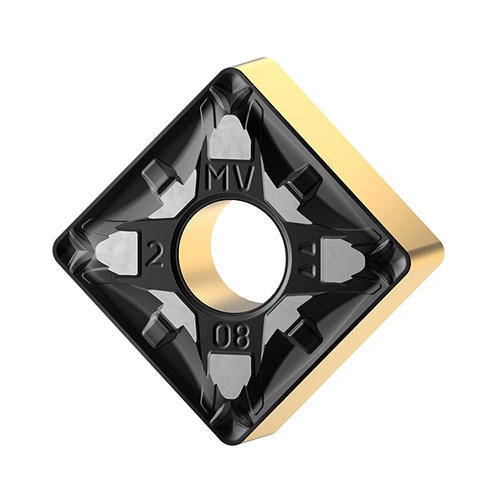

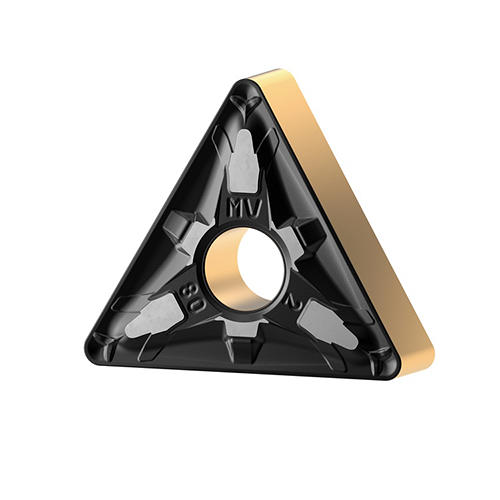

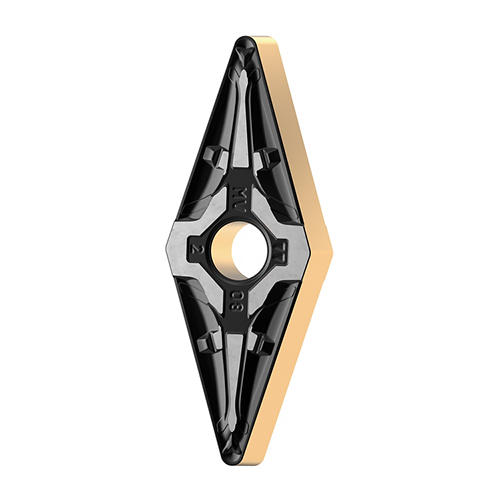

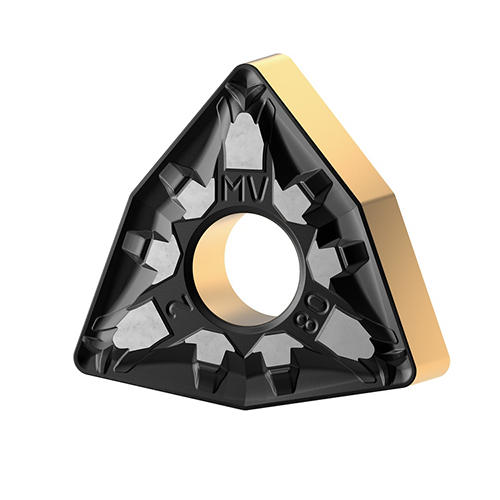

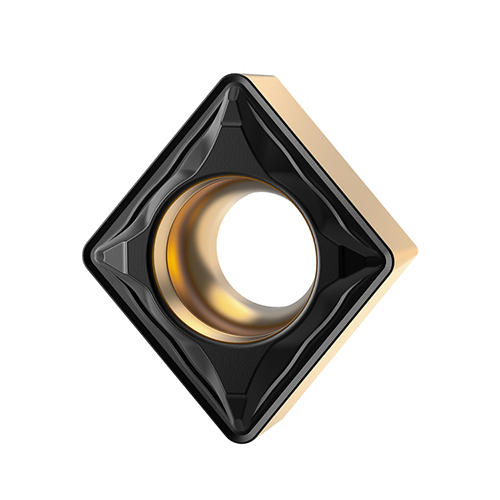

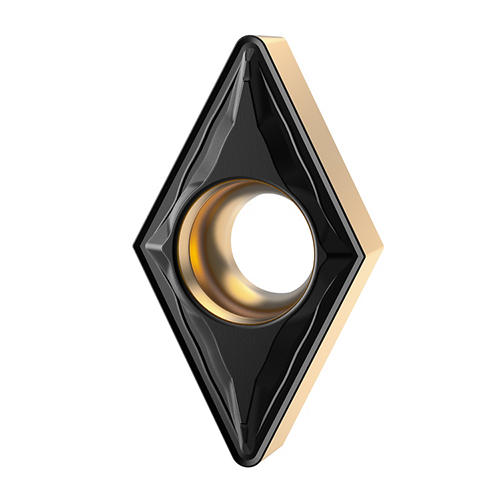

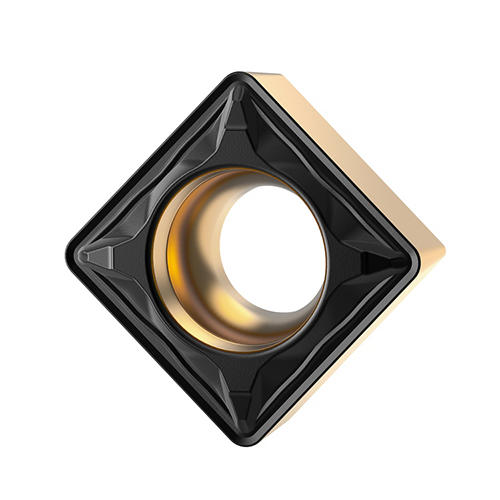

Discover the most reliable insert coating for enhanced edge protection in turning applications.

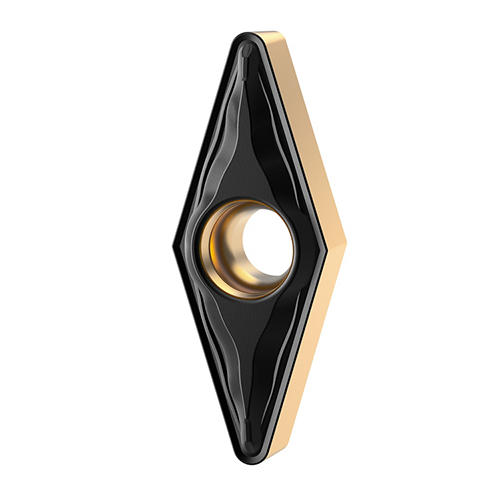

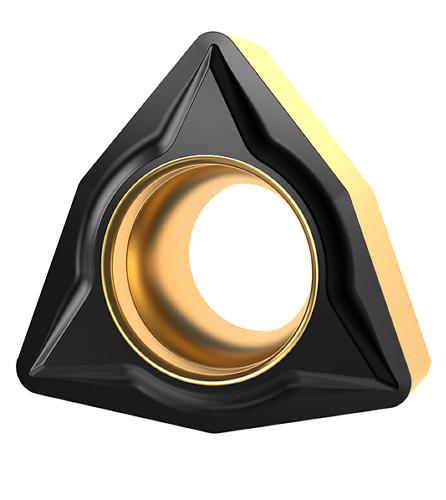

KENGold is the next generation of CVD coating technologies featuring uniform layers that resist abrasion, provide a strong thermal barrier, improve edge toughness, and allow for easy detection of wear due to its gold flank.

Leveraging advanced pressing and honing technologies, Kennametal has achieved consistently tight tolerance levels with KENGold and has applied the advanced coating to the KCP25C grade. The grade is extremely versatile when machining steel in a wide range of turning applications. It offers improved toughness and resistance to abrasion and chipping.

Applied to the turning insert grades, in combination with enhanced edge preparation features, customers will experience more reliable and consistent tool life.