Produkt podobny do:

HARVI™ II • Square End • 5 Flutes • Plain Shank • Inch

HARVI™ II Solid Carbide End Mill for Roughing and Finishing of Multiple Materials

Nr materiału3899139

Nr katalogowy ISOUCDE438J5BSNr katalogowy ANSIUCDE438J5BS

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Trochoidal Milling

Ramping: 3°

Slotting: Square End

Side Milling/Shoulder Milling: Square End

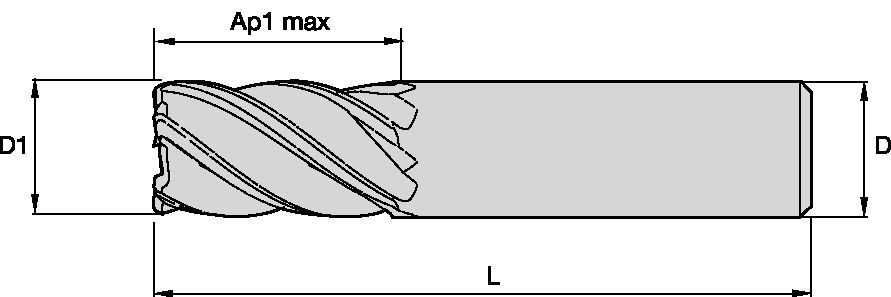

Tool Dimensions: Flute Configuration: 5

Helix Angle: 38°

Corner Style: Corner Radius

Corner Style: Square End

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Nr materiału | 3899139 |

| Nr katalogowy ISO | UCDE438J5BS |

| Nr katalogowy ANSI | UCDE438J5BS |

| Grade | KC643M |

| Adapter Style Machine Side | Straight-Cylindrical |

| [Z] Number of Flutes | 5 |

| [D1] Effective Cutting Diameter | 11.113 mm |

| [D1] Effective Cutting Diameter | 0.4375 in |

| [D] Adapter / Shank / Bore Diameter | 11.113 mm |

| [D] Adapter / Shank / Bore Diameter | 0.4375 in |

| [AP1MAX] 1st Maximum Cutting Depth | 25.4 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1 in |

| [L] Overall Length | 63.5 mm |

| [L] Overall Length | 2.5 in |

Materiały przedmiotu obrabianego

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Zastosowania

Trochoidal Milling

Ramping: 3°

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 5

Helix Angle: 38°

Corner Style: Corner Radius

Corner Style: Square End

Gatunki

KC643M

Coated fine-grain grade with PVD multilayer (AlTiN). KC643M™ is a very thin and hard PVD coating particularly suited for cutting steel, cast iron, stainless steel (wet), and titanium (wet). This grade can be used for materials with hardness up to 52 HRC.

Właściwości i zalety

- Versatile solid carbide end mill for steels, stainless steel, cast iron and hard materials

- HARVI™ II solid carbide end mills cover a variety of operations, including dynamic milling

- HARVI™ II solid carbide end mills feature unequal flute spacing for chatter-free machining at highest feed rates

- Slotting up to 1xD

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

Tolerancja

| Tolerancje frezów trzpieniowych | |||

| D1 | tolerancja | D | Tolerancja h6 + / - |

| All | +.000/- .002" | ≤1/8" | +0/-.00024" |

| +0/-.00031" | |||

| +0/-.00035" | |||

| +0/-.00043" | |||

| 0/.00051" | |||

Parametry skrawania

HARVI II • UCDE • Unequal Flute Spacing

|  |  | |||||||||||||

| Frezowanie walcowe (A) i Frezowanie rowków (B) | |||||||||||||||

| KC643M | KCPM15 | Recommended feed per tooth (IPT=inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | |||||||||||||

| A | B | Prędkość skrawania | |||||||||||||

| frac. | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||||

| Grupa materiałowa | ap | ae | ap | min | max | min | max | dec. | .250 | .375 | .500 | .625 | .750 | 1.000 | |

| P | 0 | 1.5 x D | 0.5 x D | 1 x D | 490 | 660 | 490 | 660 | IPT | .0018 | .0027 | .0034 | .0039 | .0044 | .0049 |

| 1 | 1.5 x D | 0.5 x D | 1 x D | 490 | 660 | 490 | 660 | IPT | .0018 | .0027 | .0034 | .0039 | .0044 | .0049 | |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 460 | 620 | 460 | 620 | IPT | .0018 | .0027 | .0034 | .0039 | .0044 | .0049 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 390 | 520 | 390 | 520 | IPT | .0015 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 4 | 1.5 x D | 0.5 x D | 0.75 x D | 300 | 490 | 300 | 490 | IPT | .0014 | .0020 | .0026 | .0030 | .0034 | .0039 | |

| 5 | 1.5 x D | 0.5 x D | 1 x D | 200 | 330 | 200 | 330 | IPT | .0012 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| 6 | 1.5 x D | 0.5 x D | 0.75 x D | 160 | 250 | 160 | 250 | IPT | .0010 | .0015 | .0019 | .0022 | .0025 | .0028 | |

| M | 1 | 1.5 x D | 0.5 x D | 1 x D | 300 | 380 | 300 | 380 | IPT | .0015 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 200 | 260 | 200 | 260 | IPT | .0012 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 200 | 230 | 200 | 230 | IPT | .0010 | .0015 | .0019 | .0022 | .0025 | .0028 | |

| K | 1 | 1.5 x D | 0.5 x D | 1 x D | 390 | 490 | 390 | 490 | IPT | .0018 | .0027 | .0034 | .0039 | .0044 | .0049 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 360 | 460 | 360 | 460 | IPT | .0015 | .0023 | .0029 | .0034 | .0039 | .0045 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 360 | 430 | 360 | 430 | IPT | .0012 | .0018 | .0023 | .0027 | .0031 | .0036 | |

| S | 1 | 1.5 x D | 0.3 x D | 0.3 x D | 160 | 300 | – | – | IPT | .0015 | .0023 | .0029 | .0034 | .0039 | .0045 |

| 2 | 1.5 x D | 0.3 x D | 0.3 x D | 80 | 130 | – | – | IPT | .0008 | .0012 | .0015 | .0018 | .0021 | .0024 | |

| 3 | 1.5 x D | 0.3 x D | 0.3 x D | 80 | 130 | – | – | IPT | .0008 | .0012 | .0015 | .0018 | .0021 | .0024 | |

| 4 | 1.5 x D | 0.5 x D | 1 x D | 160 | 200 | – | – | IPT | .0011 | .0017 | .0021 | .0025 | .0028 | .0033 | |

| H | 1 | 1.5 x D | 0.5 x D | 0.75 x D | 260 | 460 | 260 | 460 | IPT | .0014 | .0020 | .0026 | .0030 | .0034 | .0039 |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use