Produkt podobny do:

Inserts for Fix-Perfect™ • Aluminium • BGHX15L5... • -GG • Roughing

Płytki do frezów FIX-PERFECT-BGHX15L5...

Nr materiału1795485

Nr katalogowy ISOBGHX15L5PCERGGTNr katalogowy ANSIBGHX15L5PCERGGT

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Nr materiału | 1795485 |

| Nr katalogowy ISO | BGHX15L5PCERGGT |

| Nr katalogowy ANSI | BGHX15L5PCERGGT |

| Grade | KD1410 |

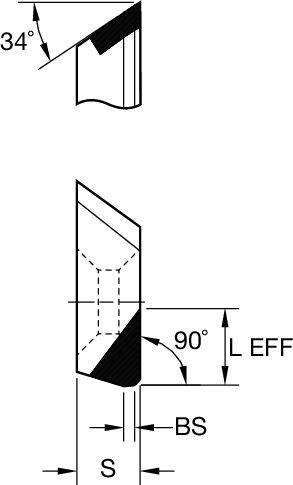

| [L10] Insert Cutting Edge Length | 5.2 mm |

| [L10] Insert Cutting Edge Length | 0.2047 in |

| [S] Insert Thickness | 5 mm |

| [S] Insert Thickness | 0.1969 in |

| [BS] Corner Facet Length | 0.9 mm |

| [BS] Corner Facet Length | 0.0354 in |

| Average Chip Thickness [HM] | 0.02 mm |

| Average Chip Thickness [HM] | 0.0008 in |

| Cutting Edges per Insert | 1 |

Materiały przedmiotu obrabianego

- Non-Ferrous

Gatunki

KD1410

A PCD-tip brazed to carbide for machining aluminum with a very high silicon content, abrasive non-ferrous materials, and fiber-reinforced plastics. KD1410 can be used at very high cutting speeds, even where good surface finishes are required. This grade can be used both wet or dry but is suggested to use coolant where good surface finishes are required.

Właściwości i zalety

- Roughing Fix-Perfect inserts for aluminum and non-ferrous materials.

- 0.374″ (9,5mm) max depth of cut.

- Two cutting edges.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

Posuwy

Recommended Starting Feeds [IPT]

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| BGHX… | .005 | .014 | .023 | .003 | .010 | .017 | .003 | .008 | .013 | .002 | .007 | .011 | .002 | .006 | .010 | BGHX… |

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

Prędkości

Recommended Starting Speeds [SFM]

| Grupa materiałowa | K110M | KC510M | KD1410 | KD1415 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | 1650 | 1550 | 1475 | 2100 | 1870 | 1720 | 13150 | 11500 | 9800 | 13150 | 11500 | 9800 |

| 3 | 1350 | 1200 | 1050 | 1900 | 1750 | 1600 | 5250 | 4900 | 4600 | 5250 | 4900 | 4600 | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

Dobór płytek

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| – | (Lekka geometria) | (Zgrubna geometria) | ||||

| – | odporność na zużycie |  | ciągliwość | |||

| – | Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | BGHX… | K110M | BGHX… | KC510M | BGHX… | KD1415 |

| N3 | BGHX… | K110M | BGHX… | KD1410 | BGHX… | KD1410 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data