Produkt podobny do:

KDMB™ • Carbide Insert • KDMB-GP • Medium Machining • Inch

Indexable Inserts

Nr materiału6784067

Nr katalogowy ISOKDMB0500M0ERGPNr katalogowy ASIKDMB0500M0ERGP

- P Steel

- M Stainless Steel

- K Cast Iron

- H Hardened Materials

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

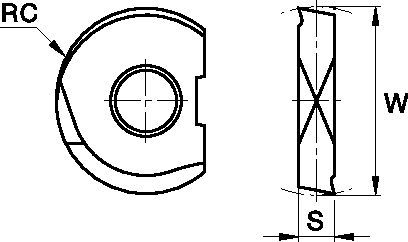

| Nr materiału | 6784067 |

| Nr katalogowy ISO | KDMB0500M0ERGP |

| Nr katalogowy ASI | KDMB0500M0ERGP |

| Grade | KCPK10 |

| [W] Cutting Width | 12.7 mm |

| [W] Cutting Width | 0.5 in |

| [S] Insert Thickness | 2.5 mm |

| [S] Insert Thickness | 0.0984 in |

| [RC] Corner Radius Center | 6.35 mm |

| [RC] Corner Radius Center | 0.25 in |

| Average Chip Thickness [HM] | 0.05 mm |

| Average Chip Thickness [HM] | 0.002 in |

Materiały przedmiotu obrabianego

- Steel

- Stainless Steel

- Cast Iron

- Hardened Materials

Gatunki

KCPK10

Composition: Advanced CVD TiCN-Al2O3 coating combined with a cobalt-enriched carbide substrate.

Application: The KCPK10 grade offers a balanced combination of deformation resistance and edge toughness leading to outstanding abrasion and crater wear resistance for high-speed machining of steel and cast iron. Use for very high cutting speeds with low to medium feed rates.

Właściwości i zalety

- High-precision helical geometry.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

Posuwy

KDMB Ball Nose • .250"

| Średnica robocza (Dw) przy osiowej głębokości skrawania (ap) | ||||

| D1 maks | ||||

At .125 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .050 Axial Depth of Cut (ap)

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

At .025 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

At .013 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .006 | .008 | .015 | .004 | .006 | .011 | .004 | .005 | .010 | .004 | .005 | .009 | .004 | .005 | .009 | .E..LD |

| .E..GP | .006 | .008 | .015 | .004 | .006 | .011 | .004 | .005 | .010 | .004 | .005 | .009 | .004 | .005 | .009 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .006 | .008 | .015 | .004 | .006 | .011 | .004 | .005 | .010 | .004 | .005 | .009 | .004 | .005 | .009 | .E..LD |

| .E..GP | .006 | .008 | .015 | .004 | .006 | .011 | .004 | .005 | .010 | .004 | .005 | .009 | .004 | .005 | .009 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

KDMB Ball Nose • .312"

| Średnica robocza (Dw) przy osiowej głębokości skrawania (ap) | ||||

| D1 maks | ||||

At .156 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .047 Axial Depth of Cut (ap)

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

At .031 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

At .016 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

KDMB Ball Nose • .375"

| Średnica robocza (Dw) przy osiowej głębokości skrawania (ap) | ||||

| D1 maks | ||||

At .188 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .056 Axial Depth of Cut (ap)

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

At .038 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

At .019 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

KDMB Ball Nose • .500"

| Średnica robocza (Dw) przy osiowej głębokości skrawania (ap) | ||||

| D1 maks | ||||

At .250 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .075 Axial Depth of Cut (ap)

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

At .050 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

At .025 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

KDMB Ball Nose • .625"

| Średnica robocza (Dw) przy osiowej głębokości skrawania (ap) | ||||

| D1 maks | ||||

At .313 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .094 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

At .063 Axial Depth of Cut (ap)

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

At .031 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • .750"

| Średnica robocza (Dw) przy osiowej głębokości skrawania (ap) | ||||

| D1 maks | ||||

At .375 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .113 Axial Depth of Cut (ap)

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

At .075 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

At .038 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

KDMB Ball Nose • 1.00"

| Średnica robocza (Dw) przy osiowej głębokości skrawania (ap) | ||||

| D1 maks | ||||

At .500 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .150 Axial Depth of Cut (ap)

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

At .100 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

At .050 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

KDMB Ball Nose • 1.25"

| Średnica robocza (Dw) przy osiowej głębokości skrawania (ap) | ||||

| D1 maks | ||||

At .625 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .188 Axial Depth of Cut (ap)

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

At .125 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

At .063 Axial Depth of Cut (ap)

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Obróbka lekka | Obróbka średnia | Obróbka ciężka |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| Geometria płytki | Rekomendowane początkowe wartości posuwu na ząb (Fz) w relacji do % zaangażowania promieniowego (ae) | Geometria płytki | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

Prędkości

Recommended Starting Speeds [SFM]

| Grupa materiałowa | K115M | KC505M | KC515M | KC530M | |||||||||

| P | 1 | – | – | – | – | – | – | 1080 | 960 | 840 | 900 | 780 | 660 |

| 2 | – | – | – | – | – | – | 1020 | 900 | 780 | 780 | 660 | 540 | |

| 3 | – | – | – | – | – | – | 900 | 780 | 660 | 660 | 600 | 540 | |

| 4 | – | – | – | 1180 | 860 | 710 | 780 | 660 | 540 | 600 | 540 | 480 | |

| 5 | – | – | – | 1180 | 860 | 710 | 660 | 540 | 420 | 540 | 480 | 420 | |

| 6 | – | – | – | 1140 | 780 | 620 | 540 | 420 | 360 | 420 | 360 | 300 | |

| M | 1 | – | – | – | – | – | – | 1080 | 900 | 780 | 900 | 720 | 600 |

| 2 | – | – | – | – | – | – | 900 | 720 | 540 | 600 | 480 | 420 | |

| 3 | – | – | – | – | – | – | 720 | 600 | 480 | 480 | 420 | 360 | |

| K | 1 | 720 | 600 | 480 | – | – | – | 1440 | 1080 | 720 | – | – | – |

| 2 | 600 | 480 | 360 | – | – | – | 1080 | 840 | 600 | – | – | – | |

| 3 | 360 | 300 | 240 | – | – | – | 480 | 360 | 240 | – | – | – | |

| N | 1–2 | 1440 | 1080 | 720 | – | – | – | – | – | – | – | – | – |

| 3 | 960 | 720 | 600 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | 300 | 230 | 160 | – | – | – | – | – | – | 260 | 200 | 170 | |

| H | 1 | – | – | – | 860 | 670 | 550 | 550 | 400 | 310 | – | – | – |

| Grupa materiałowa | K115M | KC505M | KC515M | KC530M | |||||||||

| P | 1 | – | – | – | – | – | – | 1080 | 960 | 840 | 900 | 780 | 660 |

| 2 | – | – | – | – | – | – | 1020 | 900 | 780 | 780 | 660 | 540 | |

| 3 | – | – | – | – | – | – | 900 | 780 | 660 | 660 | 600 | 540 | |

| 4 | – | – | – | 1180 | 860 | 710 | 780 | 660 | 540 | 600 | 540 | 480 | |

| 5 | – | – | – | 1180 | 860 | 710 | 660 | 540 | 420 | 540 | 480 | 420 | |

| 6 | – | – | – | 1140 | 780 | 620 | 540 | 420 | 360 | 420 | 360 | 300 | |

| M | 1 | – | – | – | – | – | – | 1080 | 900 | 780 | 900 | 720 | 600 |

| 2 | – | – | – | – | – | – | 900 | 720 | 540 | 600 | 480 | 420 | |

| 3 | – | – | – | – | – | – | 720 | 600 | 480 | 480 | 420 | 360 | |

| K | 1 | 720 | 600 | 480 | – | – | – | 1440 | 1080 | 720 | – | – | – |

| 2 | 600 | 480 | 360 | – | – | – | 1080 | 840 | 600 | – | – | – | |

| 3 | 360 | 300 | 240 | – | – | – | 480 | 360 | 240 | – | – | – | |

| N | 1–2 | 1440 | 1080 | 720 | – | – | – | – | – | – | – | – | – |

| 3 | 960 | 720 | 600 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | 300 | 230 | 160 | – | – | – | – | – | – | 260 | 200 | 170 | |

| H | 1 | – | – | – | 860 | 670 | 550 | 550 | 400 | 310 | – | – | – |

Dobór płytek

KDMB Ball Nose Platform • .250"

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| – | (Lekka geometria) | – | (Zgrubna geometria) | |||

| – | odporność na zużycie |  | ciągliwość | |||

| – | Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| (Lekka geometria) | (Zgrubna geometria) | |||||

| odporność na zużycie |  | ciągliwość | ||||

| Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek | |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC515M | .E..GP | KC515M | – | – |

KDMB Ball Nose Platform • .312"

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| – | (Lekka geometria) | – | (Zgrubna geometria) | |||

| – | odporność na zużycie |  | ciągliwość | |||

| – | Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | – | – | – | – |

| K3 | .E..GP | KC515M | – | – | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| (Lekka geometria) | (Zgrubna geometria) | |||||

| odporność na zużycie |  | ciągliwość | ||||

| Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek | |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | – | – | – | – |

| K3 | .E..GP | KC515M | – | – | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

KDMB Ball Nose Platform • .375"

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| – | (Lekka geometria) | – | (Zgrubna geometria) | |||

| – | odporność na zużycie |  | ciągliwość | |||

| – | Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| (Lekka geometria) | (Zgrubna geometria) | |||||

| odporność na zużycie |  | ciągliwość | ||||

| Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek | |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

KDMB Ball Nose Platform • .500"

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| – | (Lekka geometria) | – | (Zgrubna geometria) | |||

| – | odporność na zużycie |  | ciągliwość | |||

| – | Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| (Lekka geometria) | (Zgrubna geometria) | |||||

| odporność na zużycie |  | ciągliwość | ||||

| Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek | |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

KDMB Ball Nose Platform • .625"

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| – | (Lekka geometria) | – | (Zgrubna geometria) | |||

| – | odporność na zużycie |  | ciągliwość | |||

| – | Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| (Lekka geometria) | (Zgrubna geometria) | |||||

| odporność na zużycie |  | ciągliwość | ||||

| Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek | |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

KDMB Ball Nose Platform • .750"

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| – | (Lekka geometria) | – | (Zgrubna geometria) | |||

| – | odporność na zużycie |  | ciągliwość | |||

| – | Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| (Lekka geometria) | (Zgrubna geometria) | |||||

| odporność na zużycie |  | ciągliwość | ||||

| Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek | |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

KDMB Ball Nose Platform • 1.00"

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| – | (Lekka geometria) | – | (Zgrubna geometria) | |||

| – | odporność na zużycie |  | ciągliwość | |||

| – | Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| (Lekka geometria) | (Zgrubna geometria) | |||||

| odporność na zużycie |  | ciągliwość | ||||

| Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek | |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

KDMB Ball Nose Platform • 1.25"

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| – | (Lekka geometria) | – | (Zgrubna geometria) | |||

| – | odporność na zużycie |  | ciągliwość | |||

| – | Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | – | – | – | – |

| K3 | .E..GP | KC515M | – | – | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | ||

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

| Grupa materiałowa | Obróbka lekka | Obróbka średnia | Obróbka ciężka | |||

| (Lekka geometria) | (Zgrubna geometria) | |||||

| odporność na zużycie |  | ciągliwość | ||||

| Geometria | Gatunek | Geometria | Gatunek | Geometria | Gatunek | |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | – | – | – | – |

| K3 | .E..GP | KC515M | – | – | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | ||

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data