Produkt podobny do:

KSEM PLUS™ B1 Heads 71.00 - 93.34mm / 2.795 - 3.674″

Głowice KSEM PLUS™ B1

Nr materiału6041937

Nr katalogowy ISOKSEMP7100FDS71B1MNr katalogowy ANSIKSEMP7100FDS71B1M

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

Drilling - Through Coolant

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Podsumowanie

- Parametry skrawania

- Do pobrania

- Pasujace produkty - strona maszyny

- Pasujace produkty - strona przedmiotu obrabianego

- Części zamienne

- Opinia

- Q&A

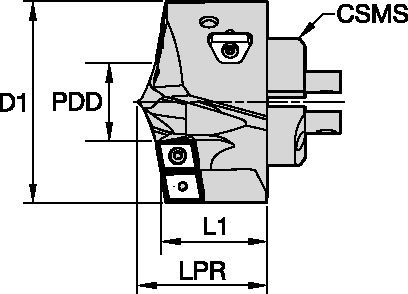

| Nr materiału | 6041937 |

| Nr katalogowy ISO | KSEMP7100FDS71B1M |

| Nr katalogowy ANSI | KSEMP7100FDS71B1M |

| [D1] Drill Diameter M | 71 mm |

| [D1] Drill Diameter M | 2.795 in |

| [PDD] Pilot Drill Cut Diameter | 26 mm |

| [PDD] Pilot Drill Cut Diameter | 1.024 in |

| [LPR] Protruding Length | 47.87 mm |

| [LPR] Protruding Length | 1.885 in |

| [L1] Insert Gage Length | 40 mm |

| [L1] Insert Gage Length | 1.575 in |

| [CSMS] System Size Machine Side | FDS71 |

| [SSC] Insert Seat Size | 5 |

Materiały przedmiotu obrabianego

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

Zastosowania

Drilling - Through Coolant

Właściwości i zalety

- Aby zapewnić 100% stabilność systemu, płytki KSEM stosowane z głowicami KSEM PLUS nie powinny być regenerowane.

- Głowice KSEM PLUS są dostarczane ze wszystkimi śrubami mocującymi płytkę.

- Głowice KSEM PLUS B1 są dostarczane z dwoma kluczami lub z trzema kluczami: jeden służydo mocowania płytek KSEM, a drugi — do mocowania płytek DFC™ i podkładek prowadzącychDPA, a także do zamontowania głowicy z korpusem wiertła. Może być również dołączony jedendodatkowy klucz, w zależności od rozmiaru podkładki prowadzącej.

- Chwyty KSEM PLUS należy zamawiać, używając rozmiaru złącza (CSMS) w celu określenia,która głowica pasuje do danego chwytu.

- Oznaczenie PDD na rysunku dotyczy wymiaru D1 płytek KSEM, HPGM oraz HPCM przeznaczonychdo stosowania z głowicami KSEM PLUS.

- Płytki (KSEM, DFC) do głowicy KSEM PLUS należy zamawiać oddzielnie.

Złóż nowe rozwiązanie aby obliczyc parametry posuwu i prędkości

Po złóżeniu rozwiązania wybierz ikonę "Posuwy i prędkości" a system pokaże rekomendowane wartości. Możesz doprecyzować wyniki dodając maszynę i jej specyfikacje lub zmień wartości początkowe Używając suwaki.

Parametry skrawania

| Metryczne | |||||||||||

| Grupa materiałowa | Warunki obróbki | Prędkość skrawania | Zalecana wartość posuwu w zależności od średnicy (fz) | ||||||||

| Zakres prędkości skrawania | |||||||||||

| Min. | Wartość początkowa | Maks. | Ø | KSEM 14….17 DFR/DFC04... 28.00 | KSEM 15….18 DFT/DFC05… 31,74 | KSEM 13….22 DFT/DFC06... 36,00 | KSEM 18….28 DFT/DFC07... 45,00 | KSEM 20….34 DFT/DFC09... 56,00 | |||

| P | 1 | S | 115 | 235 | 290 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 |

| U | 90 | 160 | 215 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 65 | 100 | 140 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 2 | S | 90 | 190 | 230 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,360 | 0,200–0,400 | 0,200–0,450 | |

| U | 71 | 130 | 170 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,360 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 80 | 110 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 3 | S | 90 | 180 | 230 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 70 | 120 | 170 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 70 | 106 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 4 | S | 90 | 140 | 220 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 70 | 110 | 160 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 80 | 110 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 5 | S | 90 | 130 | 210 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 70 | 100 | 150 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 70 | 100 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 6 | S | 70 | 90 | 180 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 50 | 75 | 120 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 40 | 60 | 100 | mm/obr. | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| M | 1 | S | 60 | 110 | 135 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 |

| U | 40 | 70 | 90 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 30 | 50 | 65 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 2 | S | 60 | 100 | 135 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 40 | 60 | 90 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 30 | 50 | 65 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 3 | S | 50 | 90 | 135 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 40 | 60 | 90 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 25 | 40 | 65 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| K | 1 | S | 90 | 170 | 230 | mm/obr. | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 |

| U | 60 | 120 | 160 | mm/obr. | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| I | 40 | 70 | 90 | mm/obr. | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| 2 | S | 90 | 160 | 220 | mm/obr. | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | |

| U | 60 | 110 | 160 | mm/obr. | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| I | 40 | 70 | 100 | mm/obr. | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| 3 | S | 90 | 150 | 210 | mm/obr. | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | |

| U | 60 | 100 | 150 | mm/obr. | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| I | 35 | 60 | 90 | mm/obr. | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| N | 1 | S | 150 | 240 | 360 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 |

| U | 100 | 160 | 240 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 100 | 160 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 2 | S | 150 | 220 | 360 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 150 | 240 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 100 | 160 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 3 | S | 150 | 200 | 360 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 4 | S | 150 | 200 | 360 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 5 | S | 150 | 200 | 360 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 6 | S | 150 | 200 | 360 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 7 | S | 110 | 220 | 260 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 70 | 140 | 170 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 45 | 90 | 110 | mm/obr. | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| S | 1 | S | 25 | 50 | 75 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 |

| U | 20 | 40 | 60 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 15 | 30 | 50 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 2 | S | 20 | 40 | 60 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 15 | 30 | 45 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 12 | 25 | 35 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 3 | S | 20 | 40 | 60 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 15 | 30 | 45 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 12 | 25 | 40 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 4 | S | 20 | 40 | 60 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 15 | 30 | 45 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 12 | 25 | 40 | mm/obr. | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| Calowe | |||||||||||

| Grupa materiałowa | Warunki obróbki | Prędkość skrawania | Zalecana wartość posuwu w zależności od średnicy (fz) | ||||||||

| Zakres prędkości skrawania [SFM] | |||||||||||

| Min. | Wartość początkowa | Maks. | Ø | KSEM 14….17 DFR/DFC04... 1.102 | KSEM 15….18 DFT/DFC05… 1.250 | KSEM 13….22 DFT/DFC06... 1.417 | KSEM 18….28 DFT/DFC07... 1.772 | KSEM 20….34 DFT/DFC09... 2.205 | |||

| P | 1 | S | 370 | 775 | 944 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 |

| U | 290 | 532 | 698 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 205 | 327 | 451 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| 2 | S | 295 | 623 | 755 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | |

| U | 233 | 427 | 558 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| I | 164 | 262 | 361 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| 3 | S | 295 | 591 | 755 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | |

| U | 230 | 394 | 558 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| I | 164 | 230 | 361 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| 4 | S | 295 | 459 | 722 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | |

| U | 230 | 361 | 525 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| I | 264 | 262 | 361 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| 5 | S | 295 | 427 | 689 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | |

| U | 230 | 328 | 689 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| I | 164 | 230 | 492 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| 6 | S | 230 | 295 | 591 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | |

| U | 164 | 246 | 394 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| I | 131 | 197 | 328 | Cal/obrót | 0.006–0.011 | 0.006–0.011 | 0.008–0.014 | 0.008–0.016 | 0.008–0.018 | ||

| M | 1 | S | 197 | 361 | 443 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 |

| U | 131 | 230 | 295 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 98 | 164 | 213 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| 2 | S | 197 | 328 | 443 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | |

| U | 131 | 197 | 295 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 98 | 164 | 213 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| 3 | S | 164 | 295 | 443 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | |

| U | 131 | 197 | 295 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 82 | 131 | 213 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| K | 1 | S | 295 | 558 | 755 | Cal/obrót | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 |

| U | 197 | 394 | 525 | Cal/obrót | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | ||

| I | 131 | 230 | 295 | Cal/obrót | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | ||

| 2 | S | 295 | 525 | 722 | Cal/obrót | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | |

| U | 197 | 361 | 525 | Cal/obrót | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | ||

| I | 131 | 230 | 328 | Cal/obrót | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | ||

| 3 | S | 295 | 492 | 689 | Cal/obrót | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | |

| U | 197 | 328 | 492 | Cal/obrót | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | ||

| I | 115 | 197 | 295 | Cal/obrót | 0.007–0.012 | 0.007–0.012 | 0.009–0.014 | 0.009–0.017 | 0.012–0.019 | ||

| N | 1 | S | 492 | 787 | 1181 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 |

| U | 328 | 525 | 787 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 197 | 328 | 525 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| 2 | S | 492 | 722 | 1181 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | |

| U | 328 | 492 | 787 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 197 | 328 | 525 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| 3 | S | 492 | 722 | 1181 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | |

| U | 328 | 492 | 787 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 197 | 328 | 525 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| 4 | S | 492 | 722 | 1181 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | |

| U | 328 | 492 | 787 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 197 | 328 | 525 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| 5 | S | 492 | 722 | 1181 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | |

| U | 328 | 492 | 787 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 197 | 328 | 525 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| 6 | S | 492 | 656 | 1181 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | |

| U | 328 | 459 | 787 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 197 | 295 | 525 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| 7 | S | 361 | 722 | 853 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | |

| U | 230 | 459 | 558 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| I | 148 | 295 | 361 | Cal/obrót | 0.005–0.008 | 0.005–0.008 | 0.006–0.011 | 0.006–0.013 | 0.008–0.016 | ||

| S | 1 | S | 82 | 164 | 246 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 |

| U | 66 | 131 | 197 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 49 | 98 | 164 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| 2 | S | 66 | 131 | 197 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | |

| U | 49 | 98 | 148 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 39 | 82 | 115 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| 3 | S | 66 | 131 | 197 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | |

| U | 49 | 98 | 148 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 39 | 82 | 131 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| 4 | S | 66 | 131 | 197 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | |

| U | 49 | 98 | 148 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| I | 39 | 82 | 131 | Cal/obrót | 0.005–0.010 | 0.005–0.010 | 0.006–0.011 | 0.006–0.013 | 0.008–0.014 | ||

| Metryczne | |||||||||||

| Warunki obróbki | Prędkość skrawania | ||||||||||

| Zakres prędkości skrawania | Zalecana wartość posuwu w zależności od średnicy (fz) | ||||||||||

| Grupa materiałowa | Min. | Wartość początkowa | Maks. | Ø | KSEM 14….17 DFR/DFC04... 28,00 | KSEM 15….18 DFT/DFC05… 31,75 | KSEM 13….22 DFT/DFC06... 36,00 | KSEM 18….28 DFT/DFC07... 45,00 | KSEM 20….34 DFT/DFC09... 56,00 | ||

| P | 1 | S | 115 | 235 | 290 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 |

| U | 90 | 160 | 215 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 65 | 100 | 140 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 2 | S | 90 | 190 | 230 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,360 | 0,200–0,400 | 0,200–0,450 | |

| U | 71 | 130 | 170 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,360 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 80 | 110 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 3 | S | 90 | 180 | 230 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 70 | 120 | 170 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 70 | 106 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 4 | S | 90 | 140 | 220 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 70 | 110 | 160 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 80 | 110 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 5 | S | 90 | 130 | 210 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 70 | 100 | 150 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 50 | 70 | 100 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| 6 | S | 70 | 90 | 180 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | |

| U | 50 | 75 | 120 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| I | 40 | 60 | 100 | mm/dev | 0,160–0,280 | 0,160–0,280 | 0,200–0,320 | 0,200–0,400 | 0,200–0,450 | ||

| M | 1 | S | 60 | 110 | 135 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 |

| U | 40 | 70 | 90 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 30 | 50 | 65 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 2 | S | 60 | 100 | 135 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 40 | 60 | 90 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 30 | 50 | 65 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 3 | S | 50 | 90 | 135 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 40 | 60 | 90 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 25 | 40 | 65 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| K | 1 | S | 90 | 170 | 230 | mm/dev | 0,180 - 0,300 | 0,180 - 0,300 | 0,216 - 0,360 | 0,240 - 0,420 | 0,300 - 0,480 |

| U | 60 | 120 | 160 | mm/dev | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| I | 40 | 70 | 90 | mm/dev | 0,180 - 0,300 | 0,180 - 0,300 | 0,216 - 0,360 | 0,240 - 0,420 | 0,300 - 0,480 | ||

| 2 | S | 90 | 160 | 220 | mm/dev | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | |

| U | 60 | 110 | 160 | mm/dev | 0,180 - 0,300 | 0,180 - 0,300 | 0,216 - 0,360 | 0,240 - 0,420 | 0,300 - 0,480 | ||

| I | 40 | 70 | 100 | mm/dev | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| 3 | S | 90 | 150 | 210 | mm/dev | 0,180 - 0,300 | 0,180 - 0,300 | 0,216 - 0,360 | 0,240 - 0,420 | 0,300 - 0,480 | |

| U | 60 | 100 | 150 | mm/dev | 0,180–0,300 | 0,180–0,300 | 0,216–0,360 | 0,240–0,420 | 0,300–0,480 | ||

| I | 35 | 60 | 90 | mm/dev | 0,180 - 0,300 | 0,180 - 0,300 | 0,216 - 0,360 | 0,240 - 0,420 | 0,300 - 0,480 | ||

| N | 1 | S | 150 | 240 | 360 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 |

| U | 100 | 160 | 240 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 100 | 160 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 2 | S | 150 | 220 | 360 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 150 | 240 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 100 | 160 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 3 | S | 150 | 200 | 360 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 4 | S | 150 | 200 | 360 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 5 | S | 150 | 200 | 360 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 6 | S | 150 | 200 | 360 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 100 | 140 | 240 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 60 | 90 | 160 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| 7 | S | 110 | 220 | 260 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | |

| U | 70 | 140 | 170 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| I | 45 | 90 | 110 | mm/dev | 0,120–0,200 | 0,120–0,200 | 0,144–0,280 | 0,160–0,320 | 0,200–0,400 | ||

| S | 1 | S | 25 | 50 | 75 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 |

| U | 20 | 40 | 60 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 15 | 30 | 50 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 2 | S | 20 | 40 | 60 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 15 | 30 | 45 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 12 | 25 | 35 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 3 | S | 20 | 40 | 60 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 15 | 30 | 45 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 12 | 25 | 40 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| 4 | S | 20 | 40 | 60 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | |

| U | 15 | 30 | 45 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

| I | 12 | 25 | 40 | mm/dev | 0,130–0,250 | 0,130–0,250 | 0,160–0,280 | 0,160–0,320 | 0,200–0,360 | ||

Tolerancja

| D1 | Tolerancja h8 + / - |

| .500–.709 | +.000/-.0010 |

| +.000/-.0013 | |

| +.000/-.0015 |

| D1 | Tolerancja h8 + / - |

| 12,5–18 | +0,000/-0,027 |

| +0,000/-0,033 | |

| +0,000/-0,039 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data