Making the Grade

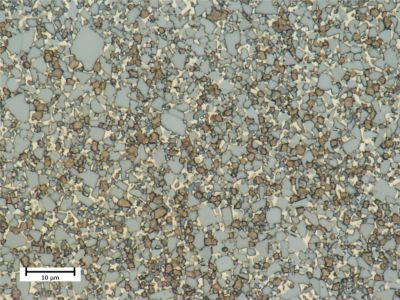

When the WC powder is then blended with powdered binders, typically Cobalt or Nickle, as well as other additives, you create a “graded powder”. Each grade has different amounts of WC and binders added, as well as varying grain size of the WC powder. Centrifuge wear parts are typically 6-10% binder, with balance made of WC, and grain sizes of under 1 micron to 3 microns in size, and with corrosion resistant additives.

Shaping the Powder

Pressing the graded powder in a die with a hydraulic press is the most economical method for smaller parts that are mass produced. Our centrifuge tiles are made using this method.

Manufacturing large or complex parts like feed and discharge nozzles, require the graded powder to be compacted into “billets” by hydrostatic pressure. By whichever of the two methods the carbide has been compacted, it is still very soft, chalk like material and is referred to as “green’’. If required, the green compact can be shaped by conventional methods of turning, drilling, milling, or grinding to create a “preform”. We are also able to produce carbide preforms using Additive Manufacturing.

Sintering

The carbide “preform’’ is then placed on a tray that is loaded into a sintering furnace and heated to the melting point of the binder, generally 2,500°F to 2,800°F. Sintering causes the part to shrink by about 20% in linear measurement and approximately 50% by volume. After cooling, you are left with a hard carbide blank.

Finishing

The carbide can be used “as-sintered” and brazed to steel, as with our tiles, epoxied and mounted with steel for certain discharge nozzles, or even finished to exact tolerances for components with critical fit.