Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Sign Out

Item(s) successfully added to cart

View Cart

View Cart

Turn up your volume for less with our limited-time offers! Shop Now

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Holemaking

- /

- Solid Carbide Drills

- /

- HP Drills • Steel • Stainless Steel • Cast Iron • Aluminum • High-Temperature Alloys

- /

- HP Drill • Coolant • Steel

- /

- B225_HP (~5 x D) • KCPK15 • F-Shank • HP Beyond Drills

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

B225_HP (~5 x D) • KCPK15 • F-Shank • HP Beyond Drills

HP Beyond™ Drills • Steel • Through Coolant

Features and benefits

- HP Beyond drills with through coolant for steel.

- Material-specific SC drill for super high-speed drilling of unalloyed and alloyed steel using standard through coolant or MQL.

- By combining unique Kennametal technologies, such as the HP point, flute geometry, and a new Beyond grade technology into one tool, the B22_HP is the ultimate high-volume production tool.

- HP point enables high feed rates by progressive rake angle.

- KCPK15™ Beyond grade is a multilayer, TiAlN-based coating with high hot hardness that enables high cutting speeds, even in MQL applications.

- The highly polished surface ensures superior chip evacuation even when low-pressure coolant is applied.

Uses and application

Drilling

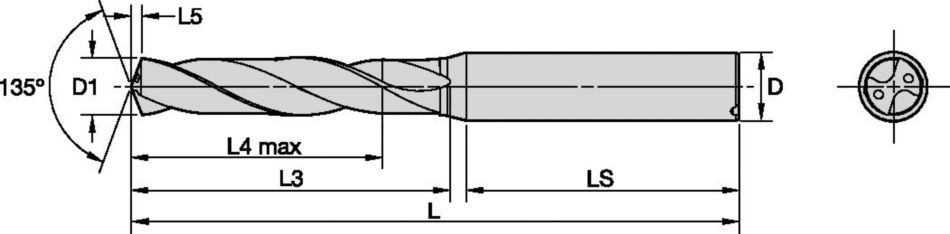

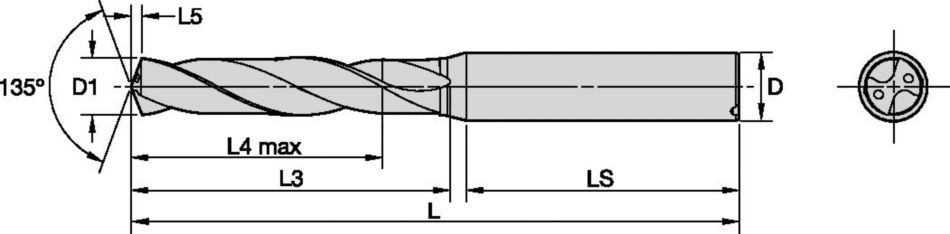

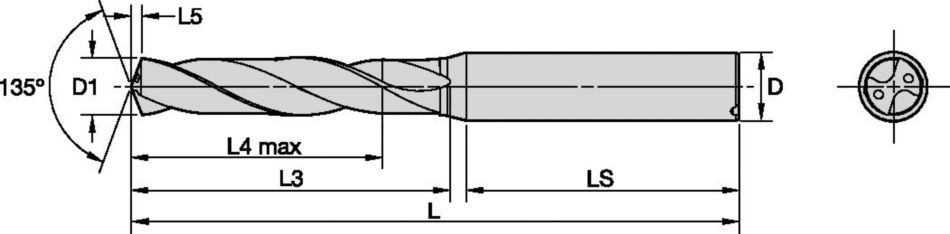

Tool Dimensions: 2flute/2margin/coolant

DIN number 6535

DIN number 6537

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Shank - Cylindrical Whistle Notch 2°

Helix Angle: 30°

| Tolerans • Metrik | ||

| Anma ölçüsü aralığı | D1 Tolerans m7 | D Tolerans h6 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 | |

| Tolerans • İnç | ||

| Anma ölçüsü aralığı | D1 Tolerans m7 | D Tolerans h6 |

| .0002/.0006 | .0000/-.0003 | |

| .0002/.0008 | .0000/-.0004 | |

| .0003/.0010 | .0000/-.0004 | |

| .0003/.0011 | .0000/-.0005 | |

Dimensions for Kennametal Solid Carbide Drills (B* Series)

| mm | KISA TİP* | UZUN TİP* | EKSTRA UZUN** | |||||||||

| Ø | DIN 6535 | ~3 x D | ~5 x D | ~8 x D | ||||||||

| D1 min | D1 maks | D | LS min | L | L3 | L4 | L | L3 | L4 | L | L3 | L4 |

| 1,000 | 1,400 | 4 | 28 | 58 | 7 | 5 | 58 | 9 | 6 | 58 | 12 | 10 |

| 1,401 | 1,900 | 4 | 28 | 58 | 9 | 6 | 58 | 12 | 9 | 58 | 18 | 15 |

| 1,901 | 2,300 | 4 | 28 | 58 | 13 | 9 | 58 | 18 | 14 | 66 | 26 | 22 |

| 2,301 | 2,990 | 4 | 28 | 58 | 17 | 12 | 58 | 22 | 17 | 66 | 30 | 25 |

| 3,000 | 3,750 | 6 | 36 | 62 | 20 | 14 | 66 | 28 | 23 | 78 | 40 | 33 |

| 3,751 | 4,750 | 6 | 36 | 66 | 24 | 17 | 74 | 36 | 29 | 87 | 49 | 41 |

| 4,751 | 6,000 | 6 | 36 | 66 | 28 | 20 | 82 | 44 | 35 | 94 | 56 | 48 |

| 6,001 | 7,000 | 8 | 36 | 79 | 34 | 24 | 91 | 53 | 43 | 105 | 67 | 57 |

| 7,001 | 8,000 | 8 | 36 | 79 | 41 | 29 | 91 | 53 | 43 | 110 | 72 | 61 |

| 8,001 | 10,000 | 10 | 40 | 89 | 47 | 35 | 103 | 61 | 49 | 122 | 80 | 68 |

| 10,001 | 12,000 | 12 | 45 | 102 | 55 | 40 | 118 | 71 | 56 | 141 | 94 | 79 |

| 12,001 | 14,000 | 14 | 45 | 107 | 60 | 43 | 124 | 77 | 60 | 155 | 108 | 91 |

| 14,001 | 16,000 | 16 | 48 | 115 | 65 | 45 | 133 | 83 | 63 | 171 | 121 | 101 |

| 16,001 | 18,000 | 18 | 48 | 123 | 73 | 51 | 143 | 93 | 71 | 185 | 135 | 113 |

| 18,001 | 20,000 | 20 | 50 | 131 | 79 | 55 | 153 | 101 | 77 | 200 | 148 | 124 |

| 20,001 | 22,000 | 20 | 50 | 141 | 86 | 60 | 167 | 112 | 85 | 217 | 162 | 136 |

| 22,001 | 25,000 | 25 | 56 | 153 | 95 | 65 | 184 | 126 | 98 | 238 | 180 | 150 |

| * D1 20 mm, DIN 6537K standardına göre | ||||||||||||

| * D1 | ||||||||||||

| ** Fabrika standardına göre | ||||||||||||

| Malzeme grubu |  |  | |||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| P | 0 | 140 | 240 | 290 | mm/dev | 0,08–0,15 | 0,09–0,18 | 0,12–0,21 | 0,14–0,29 | 0,15–0,33 | 0,17–0,37 | 0,19–0,43 | 0,22–0,49 |

| 1 | 130 | 240 | 290 | mm/dev | 0,09–0,18 | 0,11–0,21 | 0,14–0,25 | 0,16–0,34 | 0,18–0,39 | 0,20–0,43 | 0,22–0,51 | 0,26–0,58 | |

| 2 | 190 | 230 | 270 | mm/dev | 0,09–0,18 | 0,11–0,21 | 0,14–0,25 | 0,16–0,34 | 0,18–0,39 | 0,20–0,43 | 0,26–0,51 | 0,32–0,58 | |

| 3 | 130 | 160 | 190 | mm/dev | 0,10–0,18 | 0,12–0,21 | 0,14–0,26 | 0,16–0,34 | 0,19–0,39 | 0,24–0,46 | 0,27–0,51 | 0,34–0,60 | |

| 4 | 110 | 150 | 170 | mm/dev | 0,07–0,16 | 0,09–0,18 | 0,14–0,26 | 0,16–0,34 | 0,17–0,36 | 0,22–0,45 | 0,25–0,52 | 0,30–0,60 | |

| 5 | 60 | 80 | 90 | mm/dev | 0,06–0,14 | 0,08–0,16 | 0,10–0,20 | 0,14–0,25 | 0,16–0,28 | 0,18–0,32 | 0,22–0,40 | 0,26–0,48 | |

| 6 | 110 | 150 | 190 | mm/dev | 0,07–0,13 | 0,11–0,16 | 0,12–0,20 | 0,15–0,28 | 0,17–0,33 | 0,19–0,37 | 0,22–0,43 | 0,25–0,48 | |

| K | 1 | 120 | 150 | 200 | mm/dev | 0,08–0,11 | 0,14–0,20 | 0,20–0,28 | 0,25–0,35 | 0,29–0,40 | 0,32–0,43 | 0,36–0,50 | 0,40–0,55 |

| 2 | 80 | 120 | 160 | mm/dev | 0,08–0,11 | 0,13–0,17 | 0,19–0,26 | 0,23–0,30 | 0,25–0,36 | 0,30–0,40 | 0,34–0,46 | 0,37–0,50 | |

| 3 | 60 | 80 | 120 | mm/dev | 0,07–0,10 | 0,10–0,14 | 0,15–0,21 | 0,19–0,26 | 0,22–0,30 | 0,24–0,33 | 0,28–0,38 | 0,30–0,41 | |

| Malzeme grubu |  |  | |||||||||||

| Malzeme grubu | Kesme hızı | İnç | |||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| P | 0 | 460 | 790 | 950 | IPR | .003–.006 | .004–.007 | .005–.008 | .006–.011 | .006–.013 | .007–.015 | .008–.017 | .009–.019 |

| 1 | 430 | 790 | 950 | IPR | .004–.007 | .004–.008 | .006–.010 | .006–.013 | .007–.015 | .008–.017 | .009–.020 | .010–.023 | |

| 2 | 620 | 750 | 890 | IPR | .004–.007 | .004–.008 | .006–.010 | .006–.013 | .007–.015 | .008–.017 | .010–.020 | .013–.023 | |

| 3 | 430 | 520 | 620 | IPR | .004–.007 | .005–.008 | .006–.010 | .006–.013 | .008–.015 | .009–.018 | .011–.020 | .013–.024 | |

| 4 | 360 | 490 | 560 | IPR | .003–.006 | .004–.007 | .006–.010 | .006–.013 | .007–.014 | .009–.018 | .010–.021 | .012–.024 | |

| 5 | 200 | 260 | 300 | IPR | .002–.006 | .003–.006 | .004–.008 | .006–.010 | .006–.011 | .007–.013 | .009–.016 | .010–.019 | |

| 6 | 360 | 490 | 620 | IPR | .003–.005 | .004–.006 | .005–.008 | .006–.011 | .007–.013 | .008–.015 | .009–.017 | .010–.019 | |

| K | 1 | 390 | 490 | 660 | IPR | .003–.004 | .006–.008 | .008–.011 | .010–.014 | .011–.016 | .013–.017 | .014–.020 | .016–.022 |

| 2 | 260 | 390 | 520 | IPR | .003–.004 | .005–.007 | .008–.010 | .009–.012 | .010–.014 | .012–.016 | .013–.018 | .015–.020 | |

| 3 | 200 | 260 | 390 | IPR | .003–.004 | .004–.006 | .006–.008 | .008–.010 | .009–.012 | .009–.013 | .011–.015 | .012–.016 | |

|  | ||||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Malzeme grubu | Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| P | 0 | 140 | 240 | 290 | mm/r | 0,08–0,15 | 0,09–0,18 | 0,12–0,21 | 0,14–0,29 | 0,15–0,33 | 0,17–0,37 | 0,19–0,43 | 0,22–0,49 |

| 1 | 130 | 240 | 290 | mm/r | 0,09–0,18 | 0,11–0,21 | 0,14–0,25 | 0,16–0,34 | 0,18–0,39 | 0,20–0,43 | 0,22–0,51 | 0,26–0,58 | |

| 2 | 190 | 230 | 270 | mm/r | 0,09–0,18 | 0,11–0,21 | 0,14–0,25 | 0,16–0,34 | 0,18–0,39 | 0,20–0,43 | 0,26–0,51 | 0,32–0,58 | |

| 3 | 130 | 160 | 190 | mm/r | 0,10–0,18 | 0,12–0,21 | 0,14–0,26 | 0,16–0,34 | 0,19–0,39 | 0,24–0,46 | 0,27–0,51 | 0,34–0,60 | |

| 4 | 110 | 150 | 170 | mm/r | 0,07–0,16 | 0,09–0,18 | 0,14–0,26 | 0,16–0,34 | 0,17–0,36 | 0,22–0,45 | 0,25–0,52 | 0,30–0,60 | |

| 5 | 70 | 90 | 110 | mm/r | 0,06–0,14 | 0,08–0,16 | 0,10–0,20 | 0,14–0,25 | 0,16–0,28 | 0,18–0,32 | 0,22–0,40 | 0,26–0,48 | |

| 6 | 60 | 80 | 100 | mm/r | 0,06–0,14 | 0,08–0,16 | 0,10–0,20 | 0,14–0,25 | 0,16–0,28 | 0,18–0,32 | 0,22–0,40 | 0,26–0,48 | |

| K | 1 | 120 | 150 | 200 | mm/r | 0,08–0,11 | 0,14–0,20 | 0,20–0,28 | 0,25–0,35 | 0,29–0,40 | 0,32–0,43 | 0,36–0,50 | 0,40–0,55 |

| 2 | 80 | 120 | 160 | mm/r | 0,08–0,11 | 0,13–0,17 | 0,19–0,26 | 0,23–0,30 | 0,25–0,36 | 0,30–0,40 | 0,34–0,46 | 0,37–0,50 | |

| 3 | 60 | 80 | 120 | mm/r | 0,07–0,10 | 0,10–0,14 | 0,15–0,21 | 0,19–0,26 | 0,22–0,30 | 0,24–0,33 | 0,28–0,38 | 0,30–0,41 | |