Why are Flat Bottom Drills Needed?

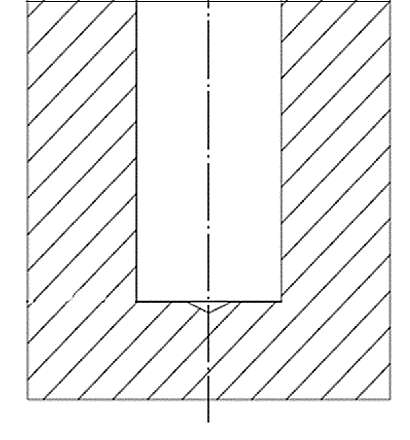

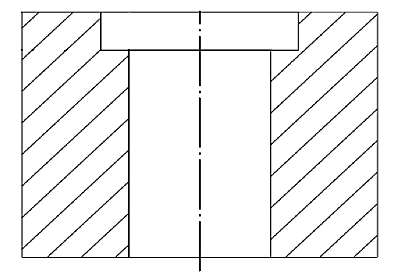

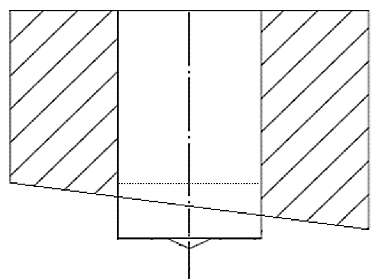

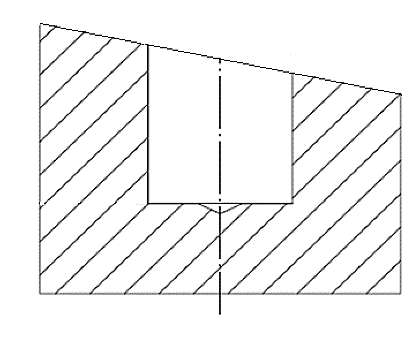

Perhaps the most common example of a flat bottom hole is one that's counterbored, which allows a socket head cap screw to sit flush with the upper surface of whatever component it's bolted to. Creating this shape requires a cutting tool with a 180-degree point. It could be a specialty tool with an obvious name—a counterbore—but in many shops, the most expedient solution is to modify an appropriately-sized drill bit and use it to cut the feature (more on this shortly). That, or interpolate the counterbore with an end mill, assuming a CNC machining center is available.